Transparent conductive laminate, method for producing same, and electrostatic capacitance type touch panel

A transparent conductive layer and transparent conductive technology, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, chemical instruments and methods, etc., can solve the problems of reduced visibility, increased manufacturing process, complicated manufacturing process, etc. Achieve high visibility and easy alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] A polyethylene terephthalate film (manufactured by Toray Co., Ltd., thickness: 100 μm) having an ultraviolet absorbing function was used as a transparent substrate, and a resin layer of the following composition was coated on both sides of the transparent substrate using a micro-gravure coater The coating liquid for formation was dried at 60° C. for 1 minute, and cured by ultraviolet rays to form a resin layer.

[0116] [Composition of Coating Liquid for Resin Layer Formation]

[0117] Resin: 100 parts by weight of Ziguang UV-7605B (manufactured by Nippon Synthetic Chemicals Co., Ltd.)

[0118]Initiator: 4 parts by weight of Irgacyua 184 (manufactured by Chiba Japan Co., Ltd.)

[0119] Solvent: 100 parts by weight of methyl acetate

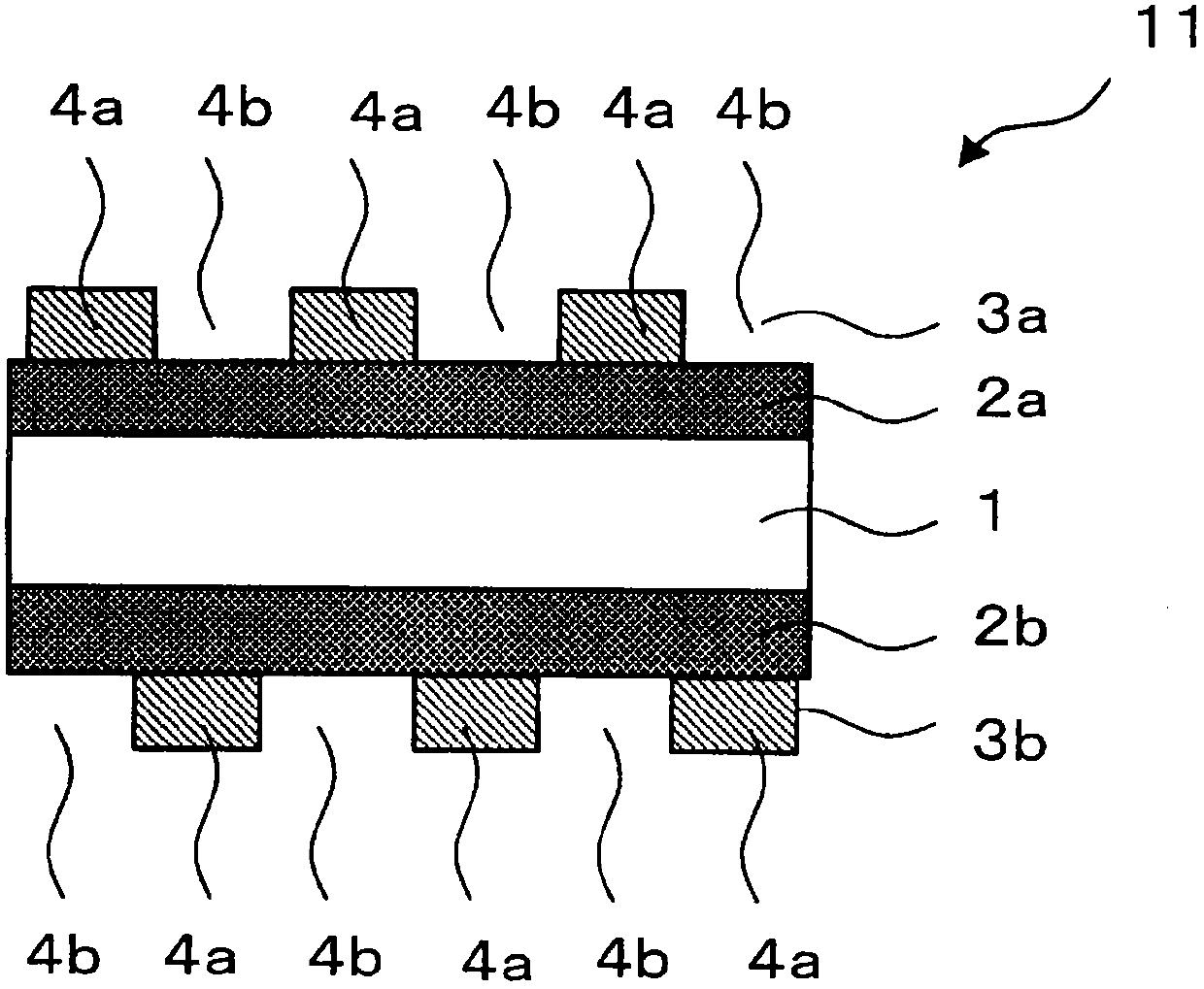

[0120] Next, on both surfaces of the resin layer formed on both surfaces of the transparent substrate, ITO was formed into a film of 30 nm by a sputtering method to form a transparent conductive layer. Then, use such as Figure 12 and ...

Embodiment 2

[0126] In addition to using a polyethylene terephthalate film (manufactured by Toray Co., Ltd., thickness: 100 μm) that does not have an ultraviolet absorbing function as a transparent substrate, and containing 0.5 parts by weight of a triazine-based ultraviolet absorbing film in the coating liquid for forming a resin layer, Agent (2-{4-[(2-hydroxy-3-tridecyloxypropyl)oxy]-2-hydroxyphenyl}-4,6-bis(2,4-dimethylphenyl) -1,3,5-triazine), using the same conditions and methods as in Example 1, a conductive pattern region and a nonconductive pattern region were formed on the transparent conductive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com