Method for improving quality of low-grade zinc oxide and removing fluorine, chlorine and arsenic in low-grade zinc oxide by reducing and roasting in rotary kiln

A low-grade zinc oxide and rotary kiln technology, applied in the field of arsenic removal, low-grade zinc oxide rotary kiln reduction roasting, defluorination, and dechlorination, can solve problems such as arsenic pollution and poor comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The low-grade zinc oxide raw material contains the following ingredients:

[0021] Zn Pb Fe As F Cl moisture 46.58 18.67 2.53 0.713 0.25 0.27 1.2

[0022] The low-grade zinc oxide raw material is added to the rotary kiln, and roasted under the conditions of high temperature and slight negative pressure in the kiln. The temperature inside the kiln is 900°C, and the temperature at the kiln tail is 550°C. For 1.5 hours, fluorine and chlorine compounds undergo physical and chemical changes, promote the decomposition of lead and zinc fluorine and chlorine compounds into a gaseous state, low-boiling point fluorine and chlorine compounds volatilize, and enter the multi-pipe lead removal system and bag dust collection with furnace gas and lead-containing smoke system and desulfurization tower tail gas treatment system, and the roasted low-level zinc oxide is cooled to the rotary kiln to obtain the finished product.

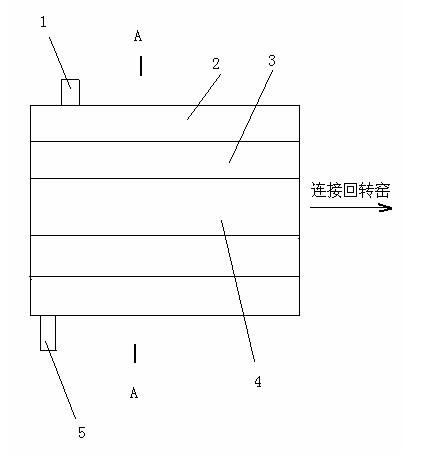

[0023] The rotary kiln is...

Embodiment 2

[0025] The raw material of low zinc oxide contains the following components: (%)

[0026] Zn Pb Fe As F Cl moisture 40 18.67 2.53 0.713 0.25 0.27 1.2

[0027] The low-grade zinc oxide raw material is added to the rotary kiln, and roasted under the conditions of high temperature and slight negative pressure in the kiln. The temperature inside the kiln is 950°C, the temperature at the end of the kiln is 650°C, the rotary kiln speed is controlled at 1.5 revolutions per minute, and the roasting time is 1 hour, following process is identical with embodiment 1. The rotary kiln is connected to a gas-coal mixed fuel burner, and the gas temperature in the first ring is 210°C.

[0028] The calcined sand produced by the rotary kiln of the above two embodiments is as follows: (%)

[0029] Zn Pb F Cl Zn can be As 1# 68.54 3.26 0.021 0.05 66.52 0.35 2# 68.15 3.46 0.027 0.04 66.84 0.30 average 68.35 3.36 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com