Production method of halide alcohol dehalogenase

The technology of a halohydrin dehalogenase and a production method, which is applied in the field of bioengineering, can solve the problem of low activity of the halohydrin dehalogenase, and achieve the effects of increasing yield and improving enzyme activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] A specific embodiment of halohydrin dehalogenase produced by the present invention is:

[0026] (1) Construct genetically engineered bacteria and prepare shake flask seed medium and fermentation medium.

[0027] (2) Activate the slant of the genetically engineered bacteria for 24 hours, then inoculate the activated genetically engineered bacteria into a 300 mL shake flask with a seed medium filling volume of 50 mL, and inoculate at 37°C at 220 r / The rotation speed of min was oscillating for 10 hours, and then the above-mentioned oscillating culture solution was inserted into the secondary shaking flask at an inoculum volume ratio of 25% according to the volume ratio of the inoculum / shaking flask seed medium, and then oscillating for 10 hours under the same conditions to obtain Seed liquid; two times of shaking flask culture is just to expand the culture amount of the strain, which is a routine operation.

[0028] (3) Put the seed liquid after shaking culture i...

Embodiment 1

[0033] Under other conditions being the same, this example uses three common carbon sources instead of glycerol as the carbon source in the fermentation medium to compare the effects of different carbon sources on the enzymatic activity of the produced halohydrin dehalogenase (see Table 1). The results showed that when lactose, sucrose and glucose were used as carbon sources, the enzyme activity was low when the addition amount was 0.6% (v / v), and the enzyme activity did not increase significantly or even decreased when the addition amount increased to 5.0%.

[0034] Table 1 The effect of carbon source on bacterial growth and enzyme production

[0035]

Embodiment 2

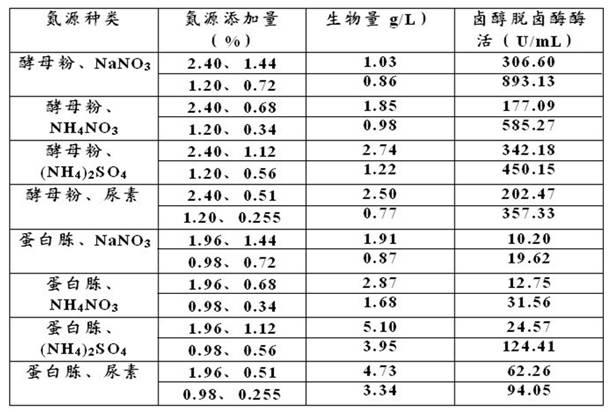

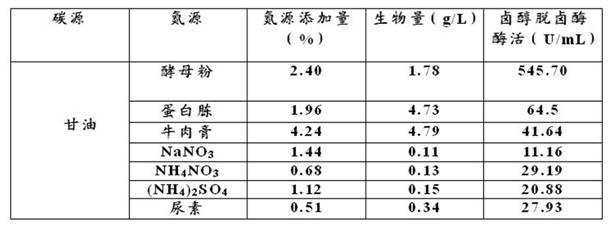

[0037] Glycerol was selected as the carbon source of the fermentation medium. Under other conditions being the same, three organic nitrogen sources including yeast powder and four inorganic nitrogen sources were used as the nitrogen sources of the fermentation medium respectively. The moles are equal to compare the effects of different nitrogen sources on the enzymatic activity of the produced halohydrin dehalogenase (see Table 2). It can be seen from Table 2 that when yeast powder is used as nitrogen source, the enzyme activity is as high as 545.7U / mL, while the biomass is only 1.78g / L; when peptone and beef extract are used as nitrogen source, although the unit enzyme activity is higher than Inorganic nitrogen sources, but the bacteria grow too fast, and a large amount of nutrients are consumed in the increase of biomass; while using inorganic nitrogen sources, although the enzyme production capacity of the bacteria is high, the total enzyme content is not high due to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com