Preparation method of thermoplastic elastomer PP special material with high fluidity and excellent permanent deformation resistance

A thermoplastic elastomer, permanent deformation technology, applied in the field of preparation of thermoplastic elastomer PP special materials, can solve the problems of high injection pressure, equipment energy consumption, large wear, high production cost, etc., to improve quality and output, high shear Power and excellent performance

Inactive Publication Date: 2012-08-15

HEILONGJIANG XINDA ENTERPRISE GRP

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the thermoplastic elastomer materials prepared by the two methods have certain improvements in the impact performance, oil resistance, oxidation resistance, ozone resistance and other properties of thermoplastic elastomers, they are not stable in the fluidity of thermoplastic elastic injection molding. There is no better improvement, especially for injection molding materials. Poor fluidity will cause the phenomenon of material shortage and weld marks in the product, which will greatly reduce the mechanical properties of the product. Energy consumption and wear are also quite large, resulting in high production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

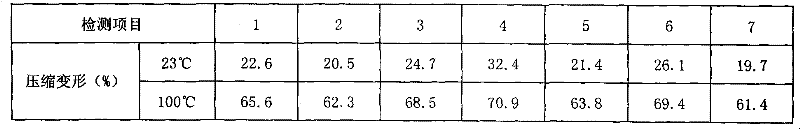

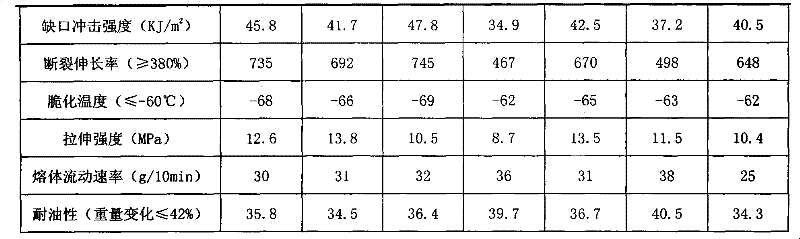

Embodiment 1-7

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a preparation method of a thermoplastic elastomer PP special material with high fluidity and excellent permanent deformation resistance. The product related in the invention facilitates low pressure injection moulding and extrusion moulding, is easy for demoulding after moulding, and has a clear product profile. The product also has good impact resistance, weatherability, ultraviolet resistance, heat resistance, oil resistance, chemical resistance, and solvent resistance which are better than those of general chloroprene rubber. The particular preparation method comprises the following steps: adding polypropylene, an elastomer, a softener, an anti-oxidant, an additive into a high speed mixer for mixing, performing melt extrusion by a double screw extruder for granulation, metering and adding a vulcanizer at a glass fiber port position during melt extrusion, and performing vulcanization crosslinking. The invention relates to a formula which comprises 50-80 parts of polypropylene, 20-50 parts of elastomers, 0-0.5 parts of softeners, 0.1-2 parts of vulcanizers, 0.1-1 parts of assisted vulcanizers, 0.5-2 parts of anti-oxidants, 0.2-1.0 parts of additives.

Description

Technical field: [0001] The invention relates to a preparation method of a thermoplastic elastomer PP special material with high fluidity and excellent permanent deformation resistance. The material prepared according to the method is applied to windshield sealing strips of high-end automobiles and high-speed trains, automobile airbag covers, anti-corrosion Dust cover, various gaskets and sealing strips, shockproof seat cushion, etc. technical background: [0002] In the era of rapid development of the automobile industry, the lightweight of automobiles is a problem that everyone pays attention to, and the safety of automobiles is the focus of everyone's attention. With the rapid increase of automobile production every year, the price of automobiles shows a downward trend. This leads to the shrinking of the performance of automobile materials, while German, Japanese, and American cars pay more attention to comfort and safety. Therefore, these high-end cars have strict requir...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/12C08L23/08C08L23/16C08L61/06C08K5/01C08K5/14

Inventor 宋阳鲍红光马俊杰翟春熙

Owner HEILONGJIANG XINDA ENTERPRISE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com