Titaniferous-spinel-added gunning mix for steel converter

A steel-making converter and spinel technology, which is applied in the field of gunning materials and gunning materials for steel-making converters, can solve the problems of poor corrosion resistance and erosion resistance, low use efficiency, and short service life, and achieve improved Anti-erosion and erosion resistance, improved production efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

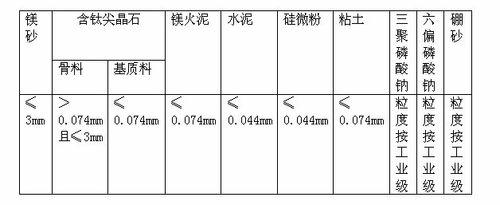

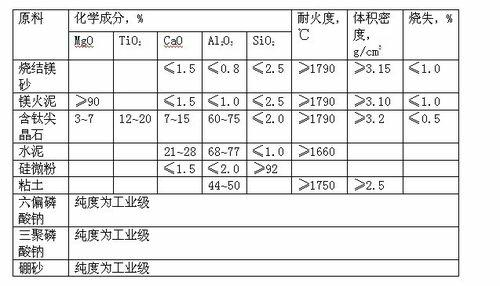

[0065] According to the performance index and particle size requirements of raw materials, by weight percentage, 50% of magnesia, 5% of titanium-containing spinel as aggregate, 10% of titanium-containing spinel as matrix material, 21% of magnesium fire clay, cement 1.5%, microsilica powder 2%, clay 3%, sodium tripolyphosphate 0.5%, sodium hexametaphosphate 4%, borax 3%, add magnesia and titanium-containing spinel to the mixing equipment first, and then sieve the borax Then add it together with magnesium fire clay, and finally add sodium hexametaphosphate, sodium tripolyphosphate, cement, silicon micropowder and clay fine powder. After fully stirring, it will be inspected and packaged to obtain the finished gunning material for steelmaking converter.

Embodiment 2

[0067] According to the performance index and particle size requirements of raw materials, by weight percentage, 60% of magnesia, 4% of titanium-containing spinel as aggregate, 6% of titanium-containing spinel as matrix material, 20% of magnesium fire clay, cement 2%, microsilica powder 3%, clay 1%, sodium tripolyphosphate 1%, sodium hexametaphosphate 1%, borax 2%, add magnesia and titanium-containing spinel to the mixing equipment first, and then sieve the borax Then add it together with magnesium fire clay, and finally add sodium hexametaphosphate, sodium tripolyphosphate, cement, silicon micropowder and clay fine powder. After fully stirring, it will be inspected and packaged to obtain the finished gunning material for steelmaking converter.

Embodiment 3

[0069] According to the performance index and particle size requirements of raw materials, by weight percentage, 53% of magnesia, 6% of titanium-containing spinel as aggregate, 8% of titanium-containing spinel as matrix material, 20% of magnesium fire clay, cement 1.4%, 4% silica powder, 1.5% clay, 0.1% sodium tripolyphosphate, 2% sodium hexametaphosphate, 4% borax, first add magnesia and titanium-containing spinel to the mixing equipment, and then sieve the borax Then add it together with magnesium fire clay, and finally add sodium hexametaphosphate, sodium tripolyphosphate, cement, silicon micropowder and clay fine powder. After fully stirring, it will be inspected and packaged to obtain the finished gunning material for steelmaking converter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com