Ultrahigh voltage electrostatic sand-planting equipment

An electrostatic sand planting and ultra-high voltage technology, applied in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve the problems of insulation system breakdown, unstable quality, difficulty in transportation, installation, commissioning and maintenance, etc., and achieve improvement reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but this embodiment is not intended to limit the present invention, and all similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

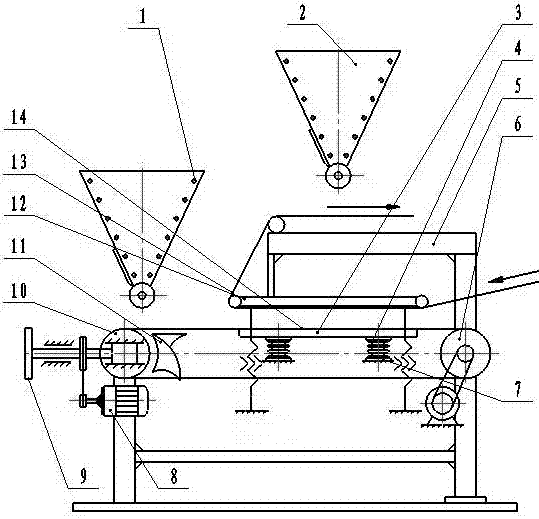

[0020] Such as figure 1 As shown, the ultra-high voltage electrostatic sand planting equipment of the present invention includes an electrostatic sand planting hopper system 1, a gravity sand planting hopper system 2, a sand delivery system 3, an ultra high voltage flat panel capacitor system 4, a bracket 5, a power transmission sand delivery roller 6, Insulation support mechanism 7, electric deviation correction mechanism 8, manual deviation correction mechanism 9, tensioning and deviation correction roller 10, additional sand discharge plate 11, low voltage plate support and height adjustment mechanism 12, abrasive cloth 13 and insulating abrasive belt 14, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com