Metal ceramic cutting tool and preparation method thereof

A technology of cermets and cutting tools, which is applied in metal processing equipment, cutting tools for lathes, milling cutters, etc., can solve the problems of high brittleness, low overall performance and service life of cutting tools, and low toughness, and achieve improved oxidation resistance, Improves toughness and prevents formation of brittle phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

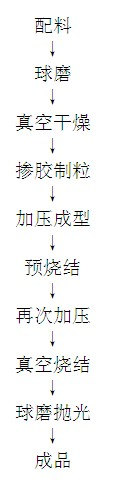

[0019] The present invention also provides a preparation method of the cermet cutter, such as figure 1 shown, including the following steps:

[0020] A. The raw materials are TiCN 30-60wt%, TiB 5-15wt%, VC 0-3wt%, MoC 10-20wt%, Ni 0-10wt%, Cu 0.5-5wt%, WC 0-15wt%, al 2 o 3 5-30wt%, TaC 0-10wt% mixed and ball milled, then dried under vacuum;

[0021] B. After adding a forming agent to the mixture of step A, granulate, pressurize and form to obtain a green body;

[0022] C. Pre-sintering the green body under vacuum to obtain a semi-finished product;

[0023] D. Pressurize the semi-finished product again, carry out vacuum sintering at a temperature higher than that of pre-sintering, and obtain a finished cermet tool after surface treatment.

[0024] In the present invention, in step A, the ball-to-material ratio during ball milling is 5:1-8:1, and the ball milling time is 24-48h. The ball milling can be carried out using a ball mill jar or a ball mill barrel, which is not ...

Embodiment 1

[0033] (1) Ingredients: Weigh raw materials according to the following parts by weight: 40 parts of TiCN, 8 parts of TiB, 2 parts of VC, 14 parts of MoC, 5 parts of Ni, 2 parts of Cu, 6 parts of WC, Al 2 o 3 19 parts, 4 parts of TaC, put the above raw materials into the alloy ball mill barrel in proportion, the ratio of ball to material is 8:1, and use absolute ethanol as the medium liquid ball mill for 24 hours; after the ball milling is completed, dry it under vacuum at a drying temperature of 70°C , The drying time is 8h.

[0034] (2) Add the molding agent PEG to the vacuum-dried system, and then granulate, and then carry out pressure molding with a pressure of 50 tons and a pressure molding time of 2 minutes to obtain a green body.

[0035](3) Pre-sinter the green body at 800°C for 60 minutes in vacuum to obtain a semi-finished tool; then pressurize the semi-finished tool again with a pressure of 70 tons for 4 minutes; then vacuum sinter at 1400°C for 1 hour, and finally...

Embodiment 2

[0038] (1) Ingredients: Weigh raw materials according to the following parts by weight: 42 parts of TiCN, 10 parts of TiB, 1 part of VC, 12 parts of MoC, 5 parts of Ni, 3 parts of Cu, 6 parts of WC, Al 2 o 3 16 parts, 5 parts of TaC, put the above raw materials into the alloy ball mill barrel in proportion, the ratio of ball to material is 6:1, and use absolute ethanol as the medium liquid ball mill for 40h; after the ball mill is completed, dry it under vacuum at a drying temperature of 100°C , The drying time is 8h.

[0039] (2) Add the molding agent PEG to the vacuum-dried system, and then granulate, and then carry out pressure molding with a pressure of 60 tons and a pressure molding time of 1 min to obtain a green body.

[0040] (3) Vacuum pre-sintering the green body at 900°C for 60 minutes to obtain a semi-finished tool; then pressurize the semi-finished tool again with a pressure of 70 tons for 4 minutes; then vacuum sinter at 1500°C for 1 hour, and finally Rough gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com