Supporting pressurization grinding roller combination module for vertical roller mill

A vertical roller mill and grinding roller technology, applied in grain processing and other directions, can solve the problems of increased height and weight of the grinding table supporting the mill, increased vibration and noise of the mill, and increased single mass of the grinding roller, etc. To achieve the effect of small vibration, small vibration of the mill, and increased dynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

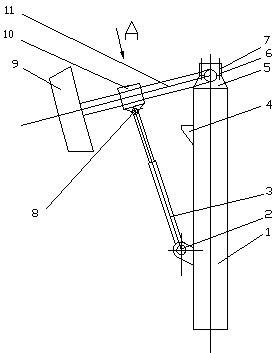

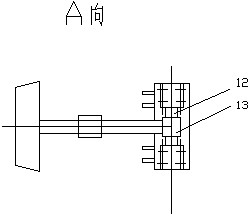

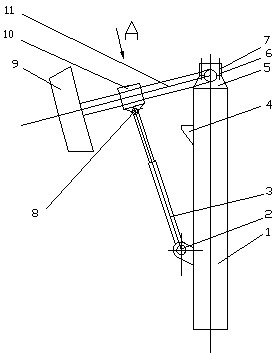

[0017] As shown in the accompanying drawing, the support 4 and the bearing seat 5 are welded on the column 1, the bearing and the bearing cover 6 are installed through the bolt 7, and the support 4 is used to install the mill ring shell and the mill shell; the two bearing seats on the same column A rotary shaft 12 is installed on the 5, and the rotary shaft 12 forms a rocker arm with the grinding roller shaft 11 through the shaft sleeve 13; the grinding roller 9 is installed on the grinding roller shaft 11, and the shaft sleeve 10 is also installed on the grinding roller shaft. One end of the hydraulic (pneumatic) spring 3 is connected, and the other end of the hydraulic (pneumatic) spring 3 is connected with the column through the pin 2. In this way, the supporting column, the rocker arm for connecting force transmission, the grinding roller for grinding and the hydraulic (pneumatic) spring for grinding and pressurization are combined into one module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com