High-pressure injection module for ordinary hydraulic injection molding machines

A high-pressure injection and injection molding machine technology, applied in the field of high-pressure injection modules, can solve the problems of injection pressure increase, high price, and system pressure should not be too high, and achieve the effect of small changes, low cost of changes, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

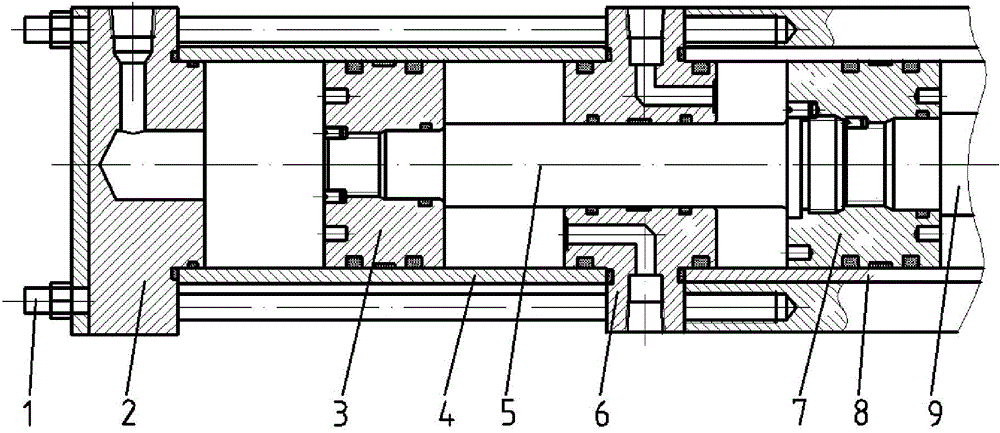

[0012] figure 1 Shown is a hydraulic cylinder for boosting, which is composed of end cover 2, boosting piston 3, boosting cylinder body 4, boosting piston rod 5 and connecting flange 6, etc. The pull rod screw 1 of 6 is connected in series with the original injection molding machine injection hydraulic cylinder cylinder 8. One end of the booster piston rod 5 is connected to the booster piston 3, and the other end is connected to the connecting piston 7 in the cylinder body 8 of the original injection molding machine injection hydraulic cylinder through the connecting flange 6, that is, connected to the original injection molding machine injection piston rod 9 , so as to realize the synchronous action of the booster piston 3 and the connecting piston 7, and the connection methods are all threaded connections.

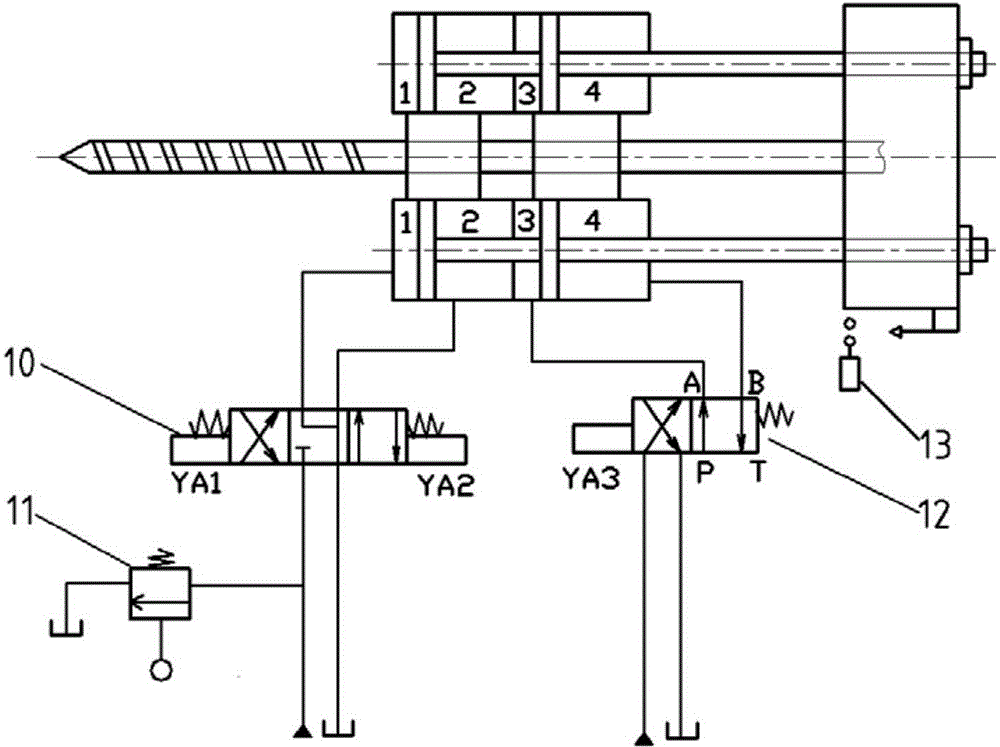

[0013] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com