The load port of the valve control unit independently controls the multi-cylinder flow distribution hydraulic system

A flow distribution and hydraulic system technology, applied in the directions of fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc., can solve problems such as inability to change flow distribution according to different requirements, inability to intervene in flow distribution, and energy loss. , to achieve good controllability and energy saving, reduce the minimum flow, maintain the effect of the highest pressure flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

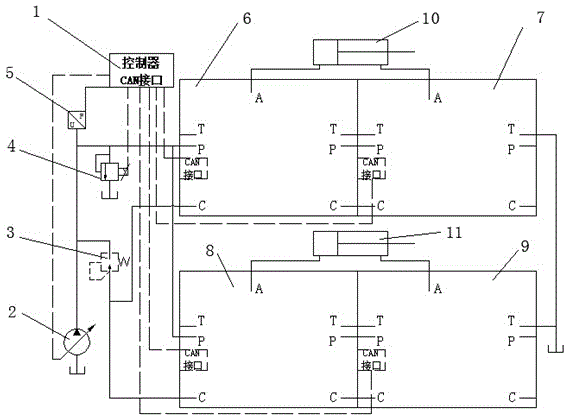

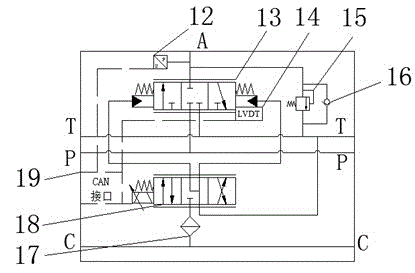

[0024] Such as figure 1 As shown, the present invention includes a controller 1, a variable displacement pump 2, a pressure reducing valve 3, a proportional relief valve 4, a first pressure sensor 5, four valve control units 6, 7, 8, 9 with the same structure, and two The hydraulic cylinders 10, 11; the oil outlet of the variable pump 2 are respectively connected to the oil inlet of the proportional relief valve 4, the oil inlet of the pressure reducing valve 3, the first pressure sensor 5, the oil inlet P of the first valve control unit 6, The oil inlet P of the second valve control unit 7, the oil inlet P of the third valve control unit 8, and the oil inlet P of the fourth valve control unit 9 are connected; the oil outlets of the pressure reducing valve 3 are respectively connected with the first valve control unit 6 The pilot oil port C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com