Double-rotor controlled alternate-running engine

An engine, dual-rotor technology, used in rotary piston engines, rotary or oscillating piston engines, engine components, etc., to solve problems such as scavenging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

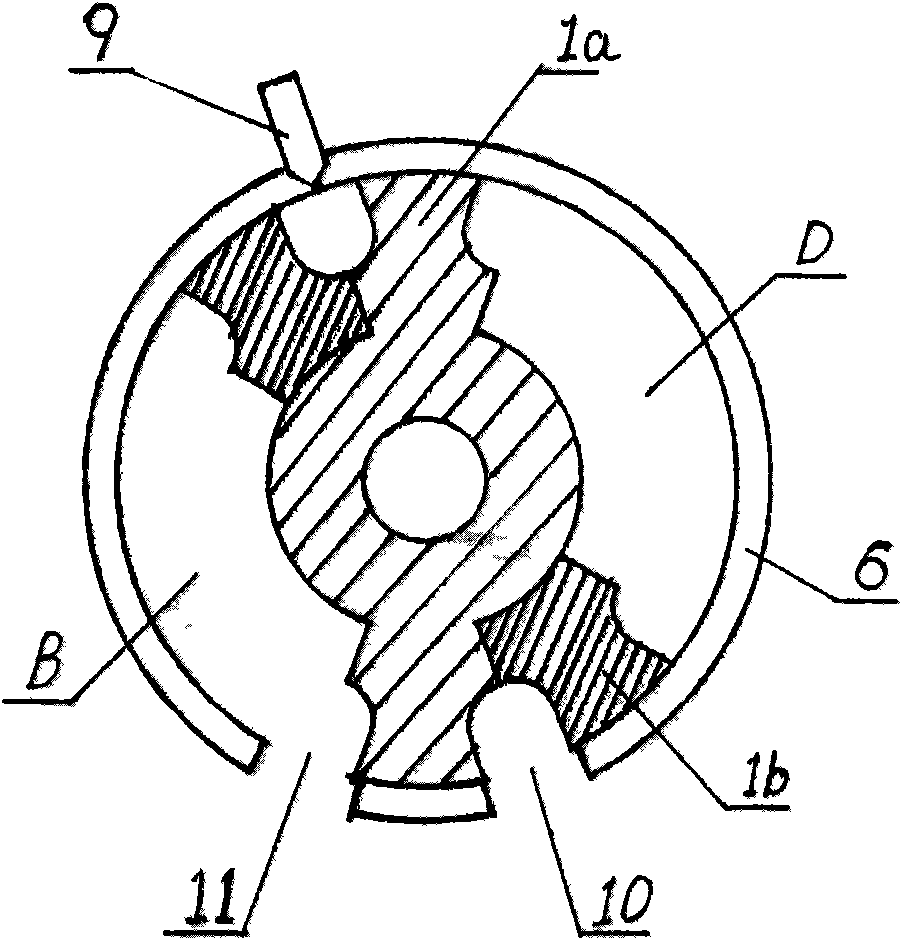

[0192] First illustrate the working principle of the engine of the present invention with Fig. 1, 2, 3, 4:

[0193] The engine in the picture is one of the different inventions of the same concept, that is, the rotor-driven controller, and the reciprocating part is an engine with a reciprocating frame:

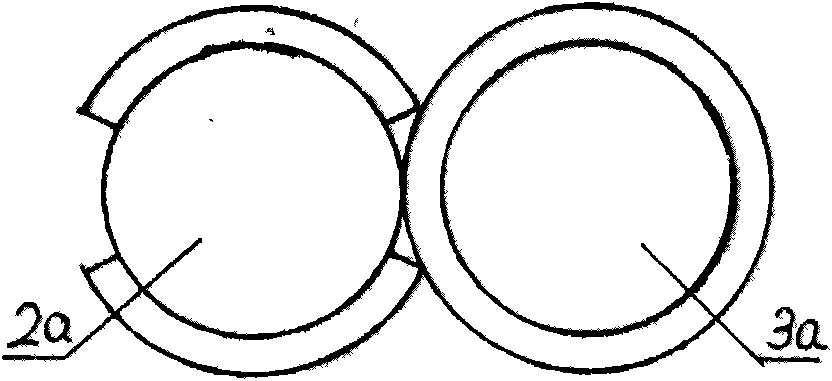

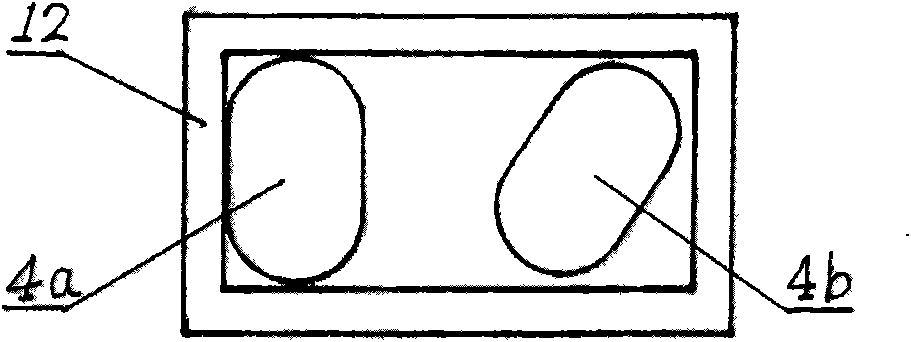

[0194] Picture 1-1 It is the diagram of the engine starting to work. The sector pistons (17) of one rotor (1a) and the other rotor (1b) are close together, the rotor (1a) cannot rotate, the spark plug or high-pressure nozzle (9) ignites or injects oil, and the rotor (1b) starts to rotate. Figure 1-2 Be that the tooth-missing position of the rotor gear (2a) of the rotor (1a) is opposite to the transmission gear (3a). Figure 1-3 It is the reciprocating part (12) in the controller that locks the control wheel (4a) of the rotor (1a), and the control wheel (4b) of the rotor (1b) rotates to jack up the reciprocating part (12). Figure 1-4 It is the rotor gear (2b) of the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com