Water control sheet, gas diffusion sheet, membrane-electrode assembly and polymer electrolyte fuel cell

A solid polymer, membrane electrode assembly technology, used in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of insufficient drainage and gas diffusion, and achieve excellent drainage and gas diffusion. , Excellent drainage and excellent operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

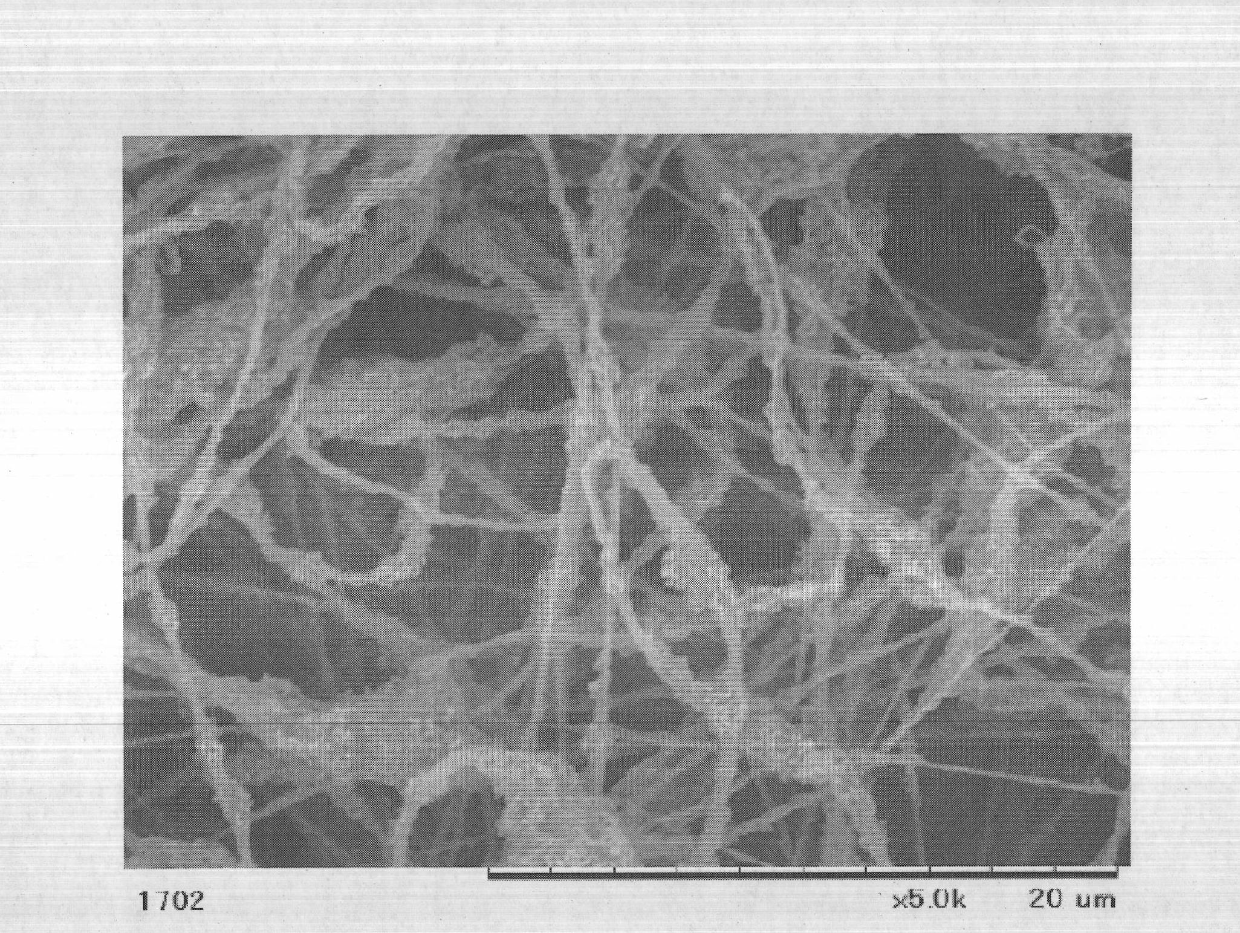

[0086] Conductive fibers spun from the first spinning solution by electrospinning were piled up on carbon paper placed on the counter electrode (conductive porous sheet, product of Toray Co.; weight per unit area: 84 g / m 2 , thickness 190μm), made of carbon paper-moisture management sheet (average fiber diameter: 380nm, weight per unit area: 6g / m 2 , Thickness: 25μm, porosity 87%) composed of gas diffusion sheet. The electron micrograph of the gas diffusion sheet is shown in figure 1 . figure 1 It was shown that in the conductive fiber, the polyvinylidene fluoride resin contained carbon black inside, and a part of the carbon black was exposed. In addition, the conductive fibers are continuous long fibers, and the long fibers are in an intertwined state during spinning. In addition, even if the moisture management sheet is peeled off from the gas diffusion sheet, the moisture management sheet remains independent and has form stability for single use. In addition, th...

Embodiment 2

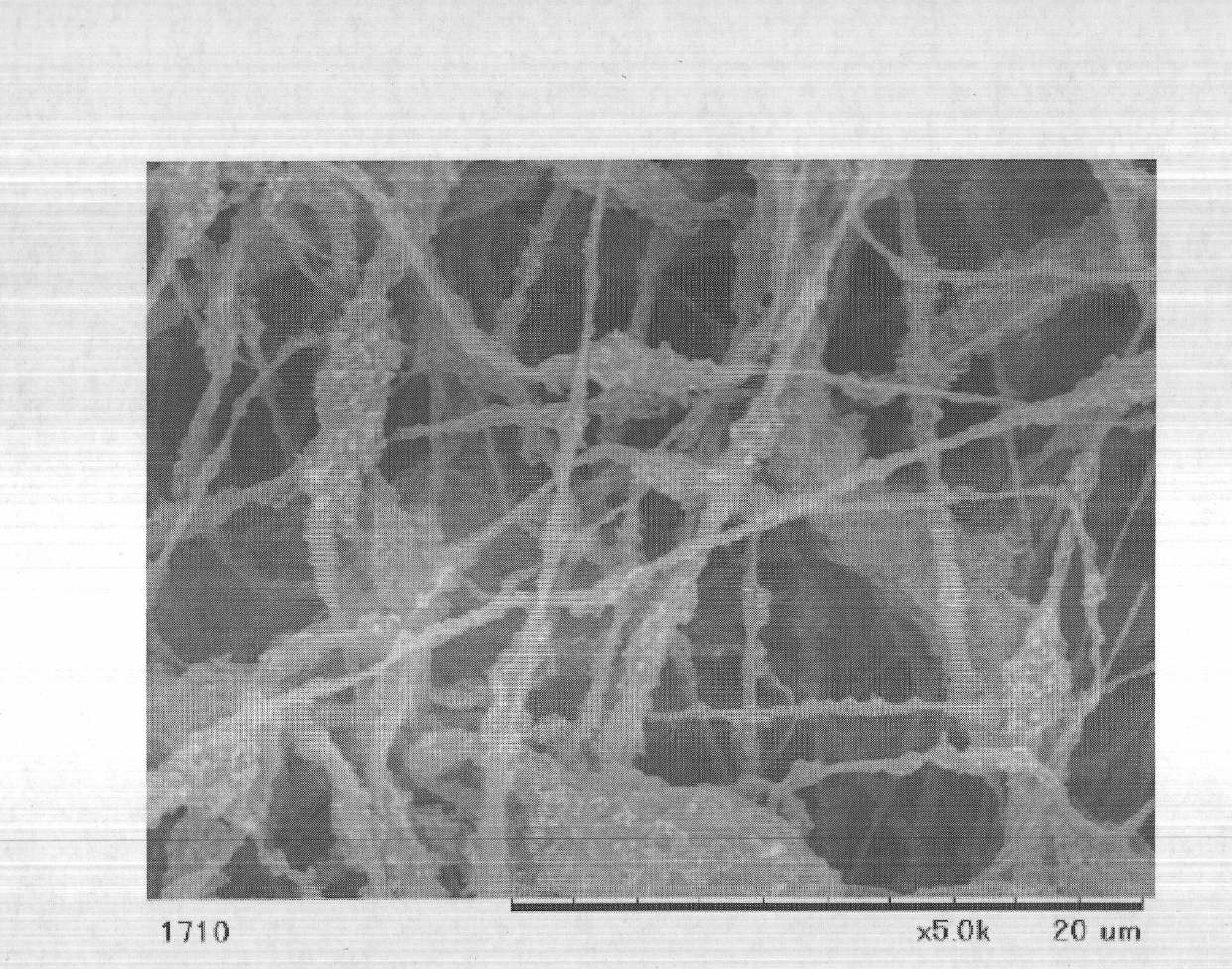

[0094] The weight per unit area of the moisture management sheet is 15g / m 2 Besides, a carbon paper-moisture management sheet (average fiber diameter: 480nm, weight per unit area: 15g / m2) was produced in the same manner as in Example 1. 2 , Thickness: 60μm, porosity 86%) composed of gas diffusion sheet. The electron micrograph of the gas diffusion sheet is shown in figure 2 . figure 2 It was shown that in the conductive fiber, the polyvinylidene fluoride resin contained carbon black inside, and a part of the carbon black was exposed. In addition, the conductive fibers are continuous long fibers, and the long fibers are in an intertwined state during spinning. In addition, even if the moisture management sheet is peeled off from the gas diffusion sheet, the moisture management sheet remains independent and has form stability for single use.

Embodiment 3

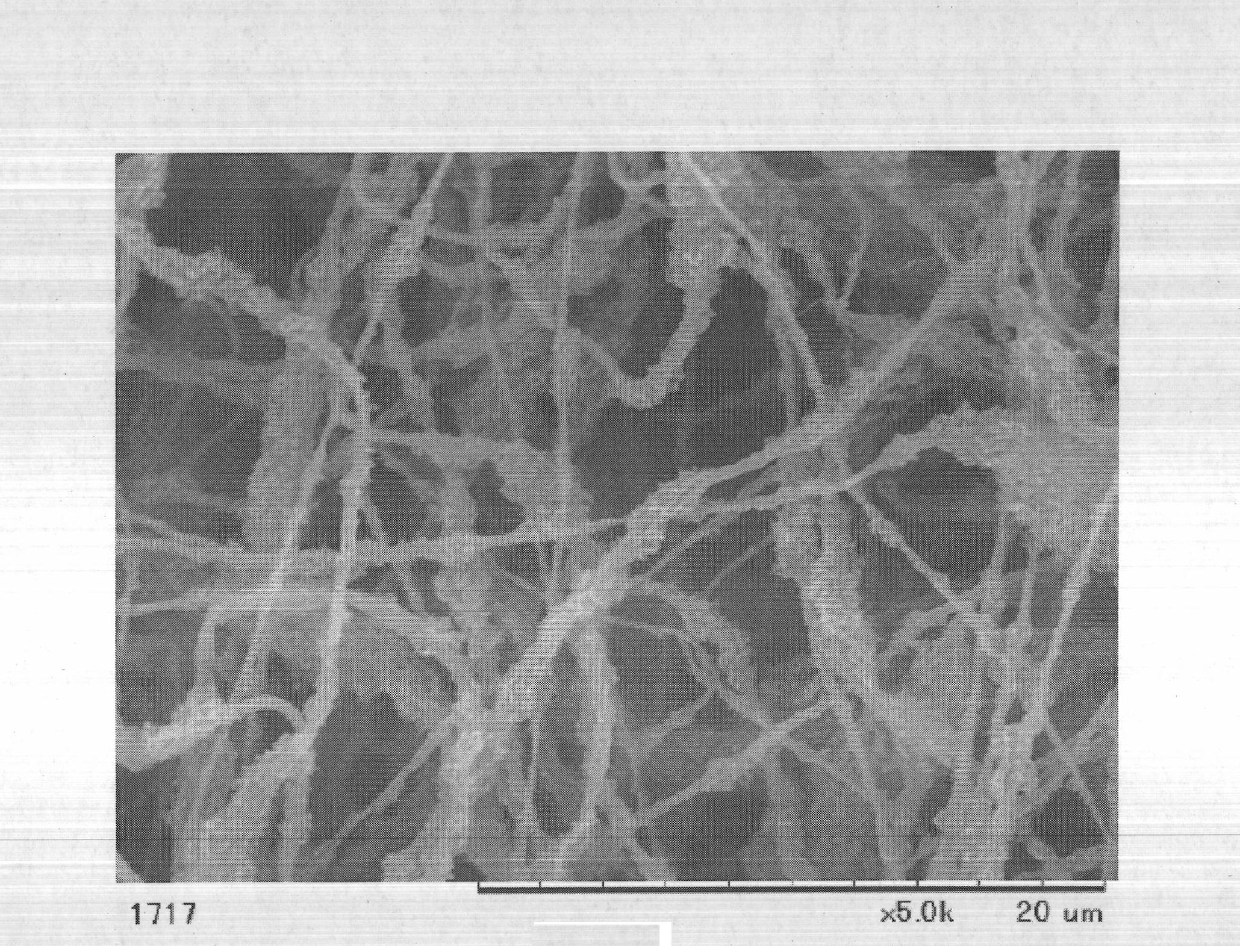

[0096] Except not using carbon paper, on the stainless steel drum that is used as counter electrode, pile up conductive fiber, by the same method as embodiment 2, made moisture management sheet (average fiber diameter: 420nm, weight per unit area: 15g / m 2 , Thickness: 60μm, porosity 86%). Electron micrographs of the moisture management sheet are shown in image 3 . image 3 It was shown that in the conductive fiber, the polyvinylidene fluoride resin contained carbon black inside, and a part of the carbon black was exposed. In addition, the conductive fibers are continuous long fibers, and the long fibers are in an intertwined state during spinning. In addition, even if the moisture management sheet is peeled off from the stainless steel drum, the moisture management sheet remains independent and has the form stability for single use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com