Superheated steam generator

A technology of superheated steam and generating device, applied in induction heating device, coil device, steam superheating and other directions, can solve the problems of poor heat transfer efficiency, lengthened heating body, small heat transfer area, etc., to improve efficiency and temperature. Controllability and the effect of large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

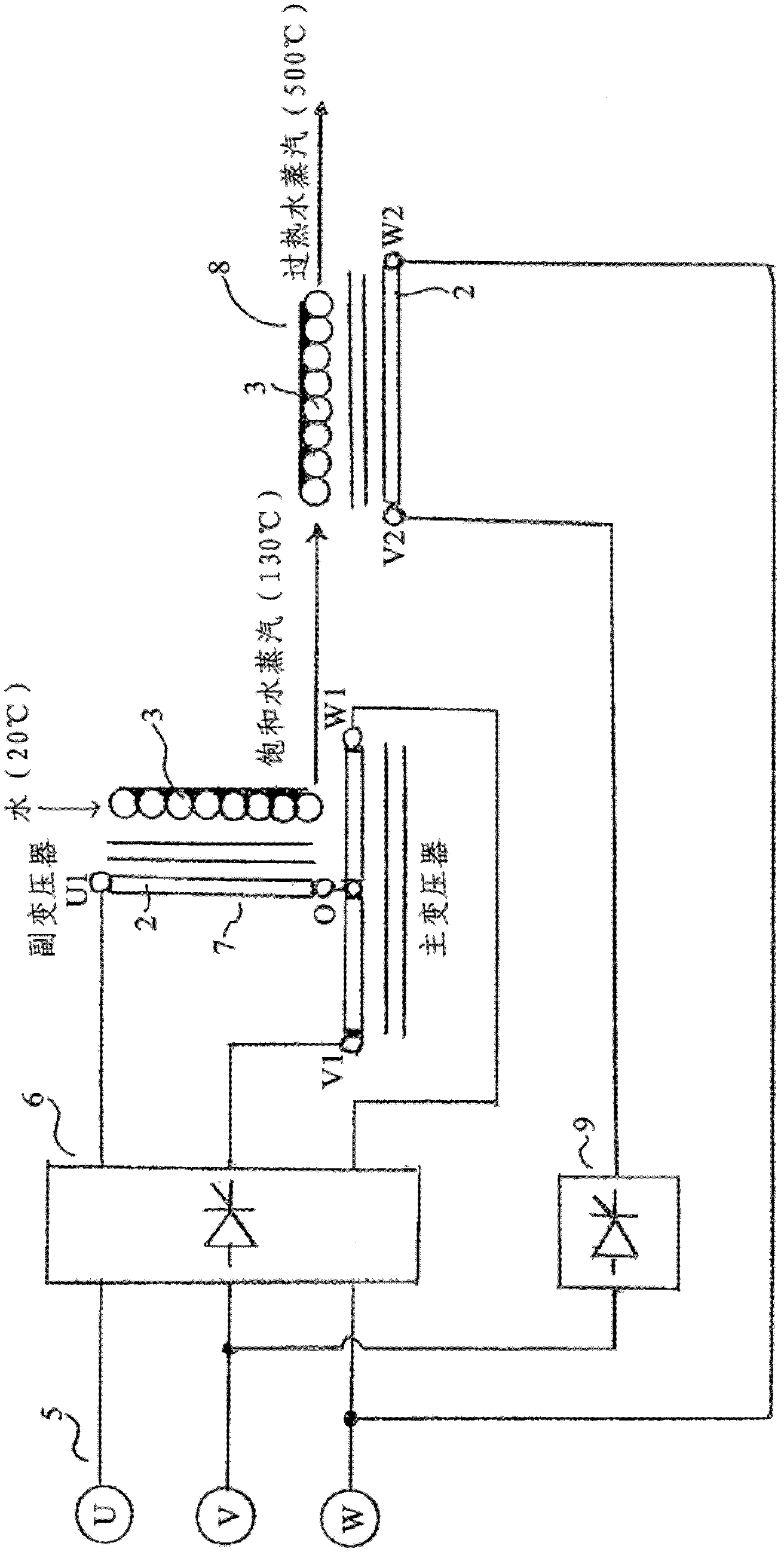

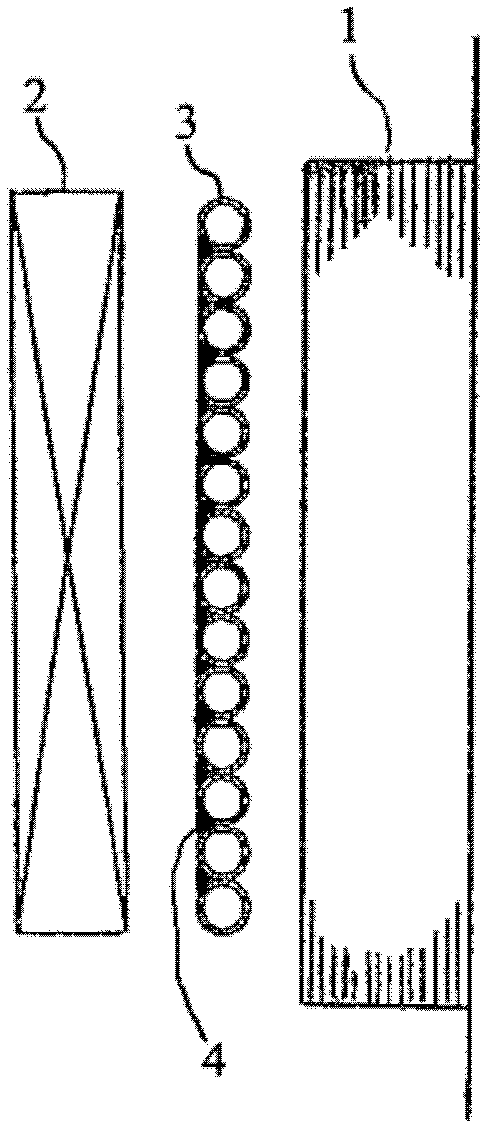

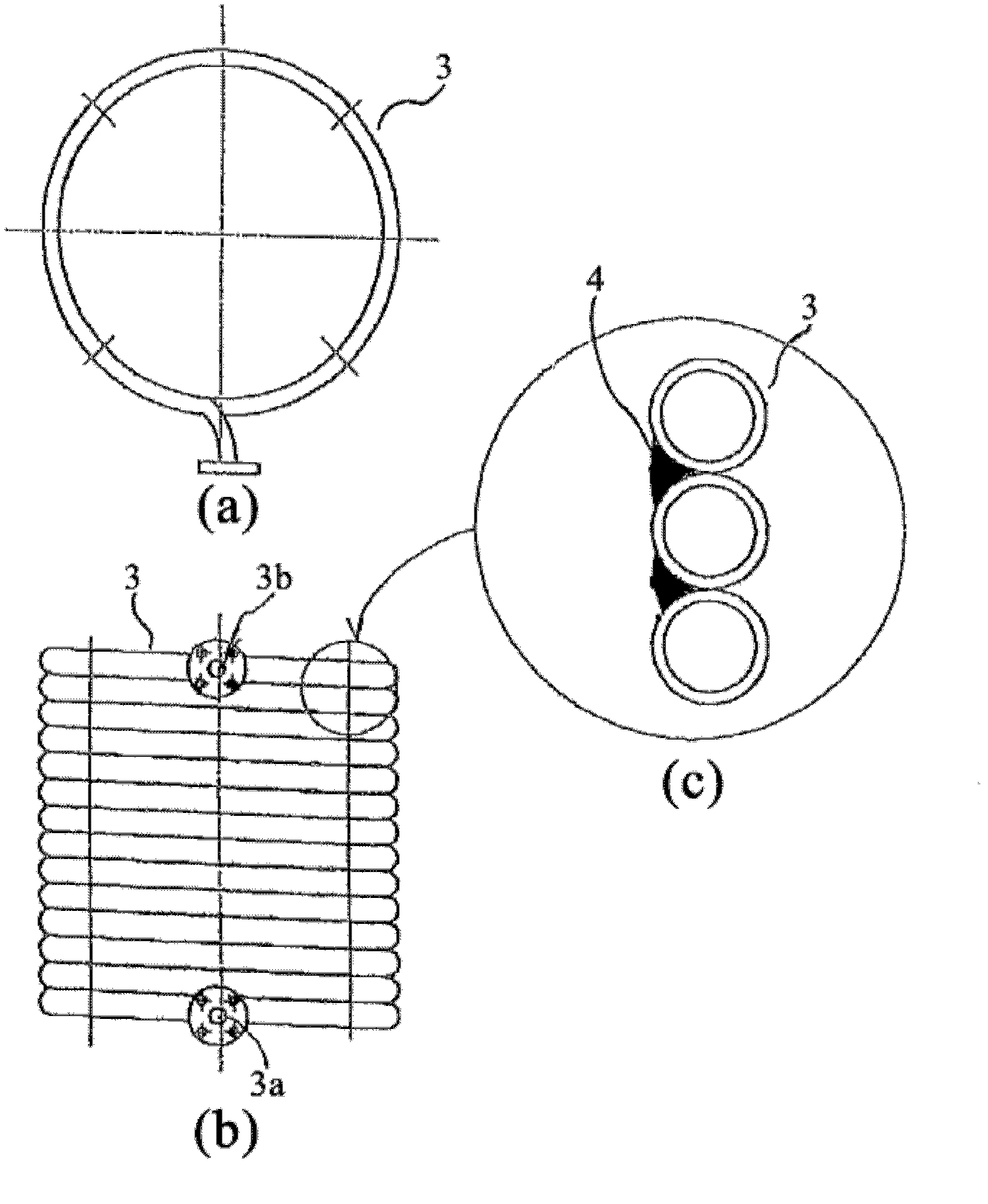

[0056] First, refer to figure 2 and image 3 The basic structure of an induction heater used in a superheated steam generator will be described. figure 2Among them, the iron core 1 constitutes a closed magnetic circuit (hereinafter referred to as the iron core, and the figure shows the column core part wound with coils), the primary coil 2 is wound on the iron core, and the conductor tube 3 is composed of SUS (stainless steel) wound on the iron core, etc. , the solder joint 4 mechanically connects and fixes the conductor pipe 3 and electrically connects the conductor pipe 3 . TIG welding is used to mechanically connect and fix the adjacent conductor tubes 3 and to electrically connect the adjacent conductor tubes 3 , so that the conductor tube 3 becomes a secondary coil with one turn that electrically short-circuits the secondary coil. Under this structure, if an AC voltage is applied to the primary coil 2, an alternating magnetic flux is generated in the iron core 1, and ...

Embodiment 2

[0067] The superheated steam generating device of this embodiment 2, like embodiment 1, is also composed of two induction heaters through the conductor pipe connecting the secondary coils of the two induction heaters, as the primary coil of each induction heater. The coil also uses a conductor tube, and water flows through the conductor tube. refer to Figure 6 and Figure 7 The induction heater used in this Example 2 will be described. Figure 6 shows the column core 11 that forms a closed magnetic circuit by the connecting core 11b, the conductor tube 12 made of copper wound on the column core (the primary coil, the illustrated example is a conductor tube with a quadrilateral cross-sectional shape), and the coil is wound on the column core. Conductor pipe 13 made of SUS or the like on the iron core (secondary coil, the illustrated example is a conductor pipe with a circular cross-sectional shape), insulating paper 15 and solvent-free insulating adhesive layer 16 .

[0068...

Embodiment 3

[0078] In the above embodiment 1 and embodiment 2, two induction heaters are used to form the superheated steam generating device, so a T-connected transformer structure and a single-phase transformer structure are used, which causes the structure of the superheated steam generating device to be complicated. It takes trouble in production. Embodiment 3 makes the structure of the superheated steam generator simpler. In said embodiment 1 and embodiment 2, two induction heaters are used, but in embodiment 3, one induction heater generating saturated water vapor among the two is divided into two, and a total of three induction heaters are used. The superheated steam generation device is constructed, and the closed magnetic circuit core (connecting core) is generalized to form a three-phase transformer structure with three columns (three cores wound with coils). With the above configuration, the phase-to-phase voltage of the three-phase AC power supply can be applied to the primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com