Miniature electrical liquid controller without tank

An electro-hydraulic controller and programming controller technology, applied in valve details, engine components, valve operation/release devices, etc., can solve the problems of wasting resources, motor overheating, and high cost of construction, and achieve convenient operation and reliable work. , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

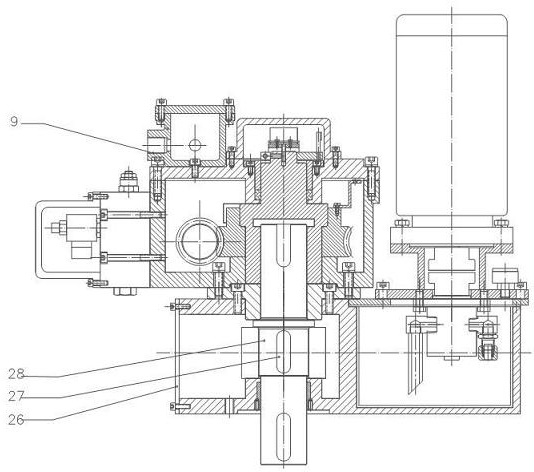

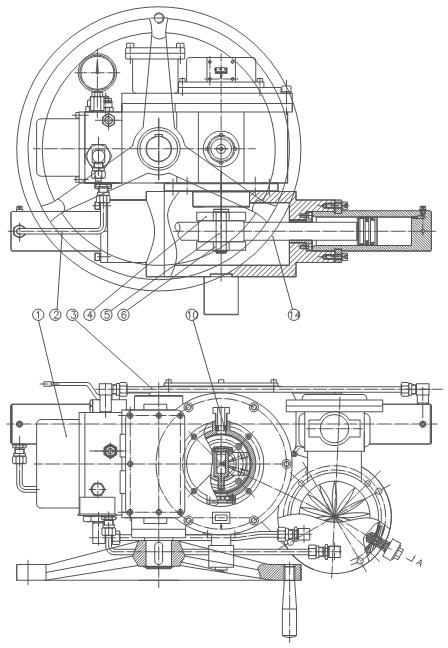

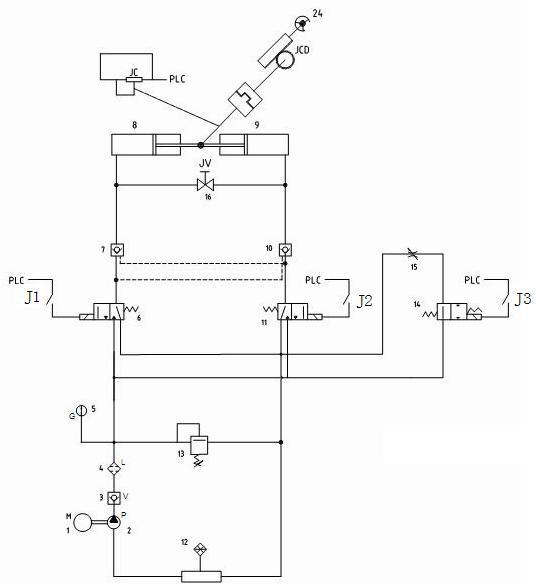

[0014] The present invention will be described in detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0015] The invention consists of a control system and a hydraulic system.

[0016] The control system of the present invention includes 4 operation modes such as instrument automatic control mode, instrument point operation control mode, fast shut-off or open operation mode, and on-site manual operation mode. The rotation angle sensor 17, the first electromagnetic valve 6, the second electromagnetic Valve 11, third solenoid valve 14, explosion-proof motor 1, first signal isolator G1, second signal isolator G2, solid state relay SSR and control circuit. The control circuit includes PLC control unit, valve control unit, SP / PV signal conversion circuit, control room, display unit and power supply unit. The hydraulic system consists of motor 1, gear pump 2, one-way valve 3, filter 4, pressure gauge 5, air filter 12, overflow valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com