Composite fiber preparation method of microwave-assisted diamond-like carbon film covered glass fiber

A technology of diamond film and glass fiber, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of decreased mechanical strength of tensile properties, restrictions on wide application, and incompatibility with social and environmental protection development, etc., to achieve Effects of improving mechanical strength, stabilizing chemical properties, and realizing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

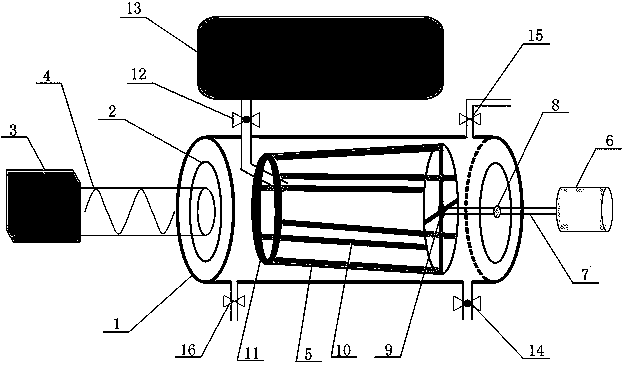

[0030] A microwave-assisted diamond-like film-coated glass fiber composite fiber preparation method, comprising the following steps:

[0031] (1) Start the microwave plasma chemical vapor deposition system, and pump the vacuum in the cylindrical stainless steel vacuum chamber 1 to 10 through the pumping valve 16 -3 Below Pa;

[0032] (2) Pass natural gas into the cylindrical stainless steel vacuum chamber 1 through the inlet valve 15 in the microwave plasma chemical vapor deposition system, so that it evenly fills the entire cylindrical stainless steel vacuum chamber 1;

[0033] (3) Start the microwave source 3 in the microwave plasma chemical vapor deposition system, so that the microwave generated by the microwave source 3 enters the cylindrical stainless steel vacuum chamber 1 from the left quartz window 2 through the waveguide 4, and the microwave in the microwave plasma chemical vapor deposition system Plasma is excited in the conical metal drum 5 to fully decompose natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com