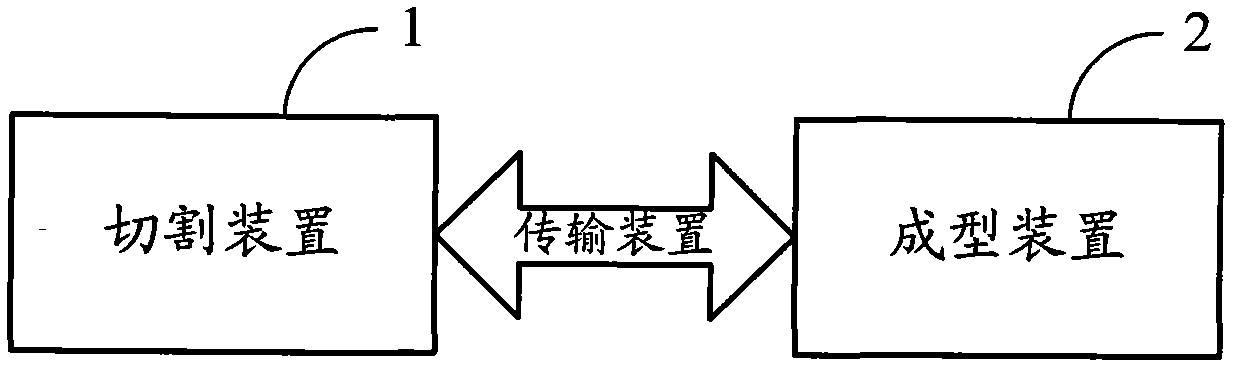

Glass/ceramic deep processing molding method and molding equipment

A molding method and deep processing technology, which is applied in the field of glass/ceramic deep processing molding methods and molding equipment, can solve the problems of ceramic parts molding and processing difficulties, and achieve the effect of improving the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

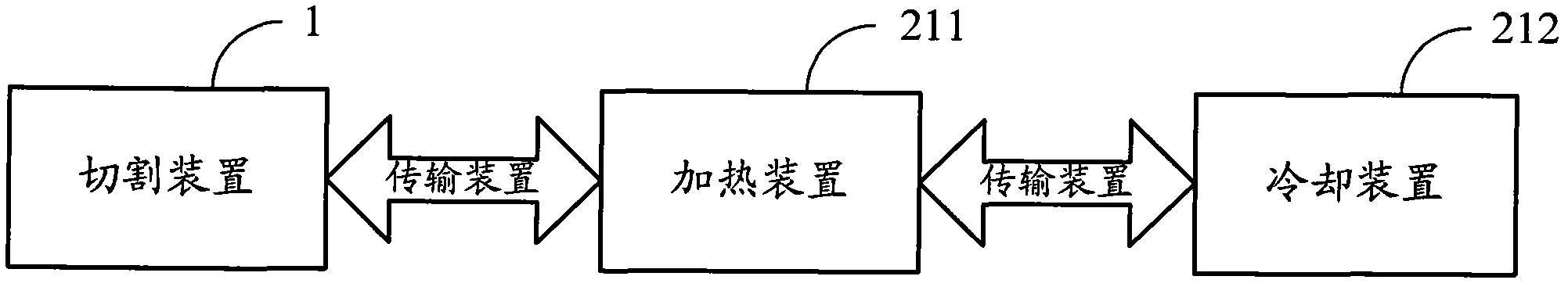

Embodiment 1

[0039] Step A11, heating the glass / ceramics to be formed with cracks in whole or in part;

[0040] Step A12, quenching the glass / ceramic on one side, so that the cracks grow along the quenching direction, so as to realize the molding of the glass / ceramic.

Embodiment 2

[0042] Step A21, locally heating the area to be formed of the glass / ceramic to be formed;

[0043] Step A22, quenching the glass / ceramics on one side to generate cracks, and making the cracks grow along the quenching direction to realize the molding of the glass / ceramics.

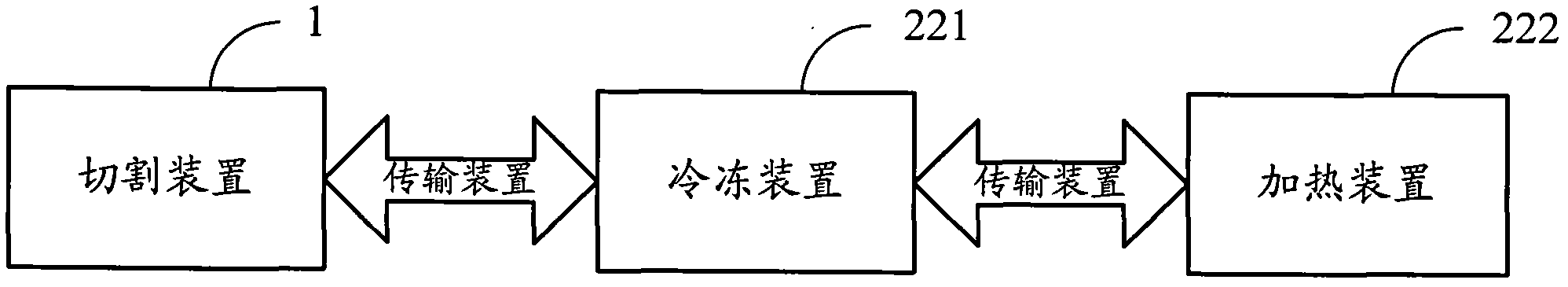

Embodiment 3

[0045] Step A31, freezing the glass / ceramic to be formed with cracks in whole or in part;

[0046] In step A32, the glass / ceramic is suddenly heated on one side, so that cracks grow along the direction of the sudden heating, and the glass / ceramic is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com