Reel cigarette pack production system based on printing quality online detection and defect treatment method

A technology of printing quality and production system, which is applied in the field of cigarette label production system and defect processing, can solve the problems of failing to meet customer quality requirements, easy fatigue of human eyes, and low production efficiency, so as to reduce loss, improve corporate image, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The product is inspected online during the bronzing process to record the exact location of all defects, and then the entire printed product is cut into 6 strips on the slitting machine, and the 8000-meter large roll is divided into 2000-meter / roll small rolls (this For example, 1 large roll can be cut into 4 cars, a total of 24 small rolls); the server software will automatically convert the product defects detected on the hot stamping machine to the corresponding small rolls after automatic conversion through preset conditions, and automatically judge Which small rolls are defective rolls (unqualified rolls); the unqualified rolls are rewound on the quality inspection machine and leave the factory, and the qualified rolls can be shipped directly.

[0039] 1. The first step of the process: bronzing + testing

[0040] (1) Process description

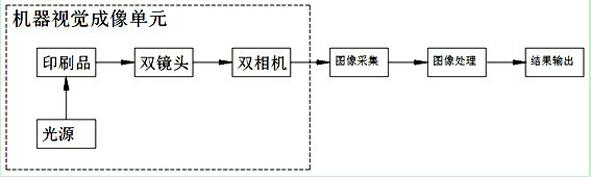

[0041] The first step of the process is to carry out online inspection on the double-station flat-bed flat-fed web stamping mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com