Surface defect detecting system of crystalline silicon polished wafer

A technology for defect detection and polishing, which is applied in the direction of optical testing for defects/defects, can solve problems such as high price, limited resolution, complex system, etc., and achieve the effects of increasing competitiveness, improving detection speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention are described in detail in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the embodiment.

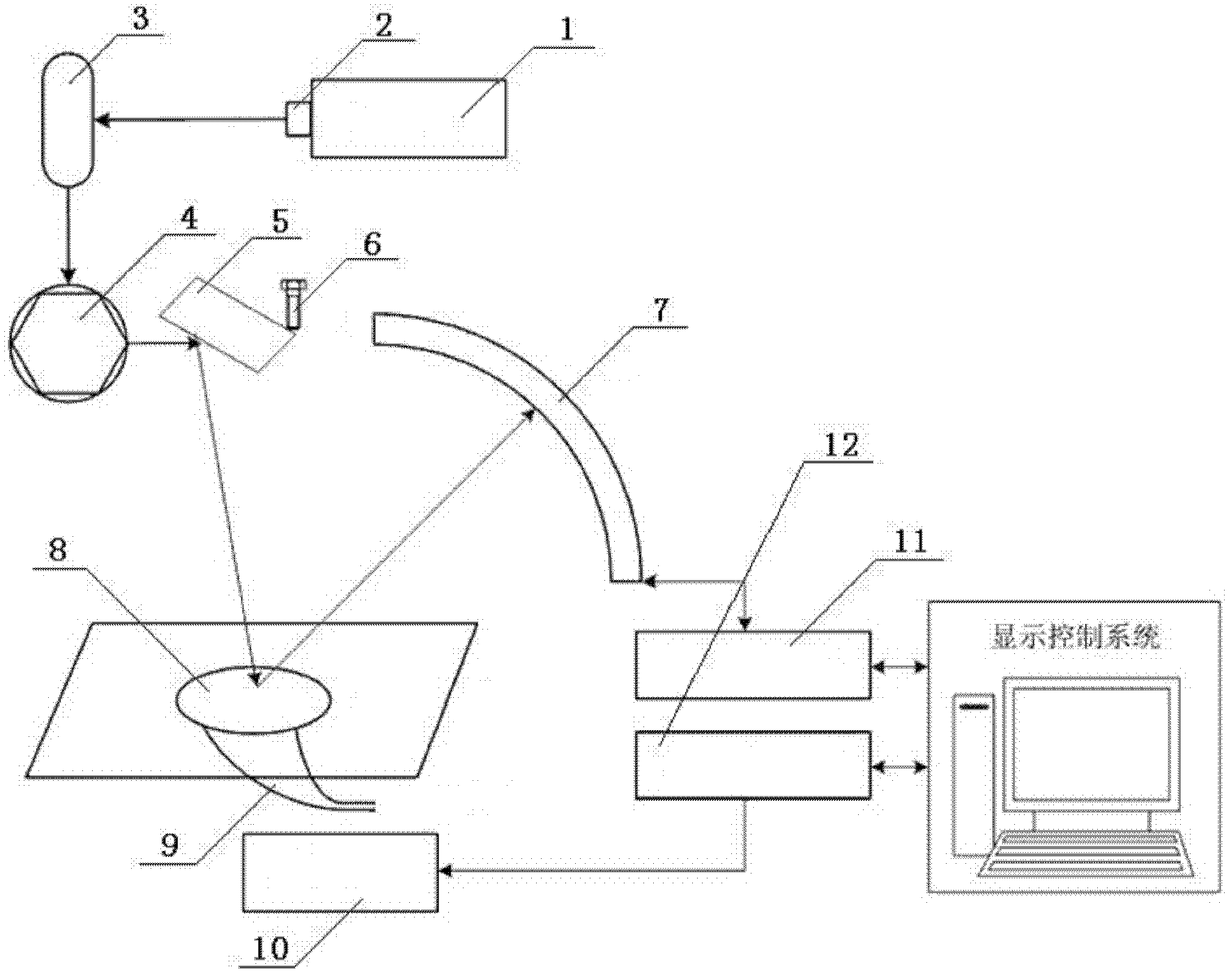

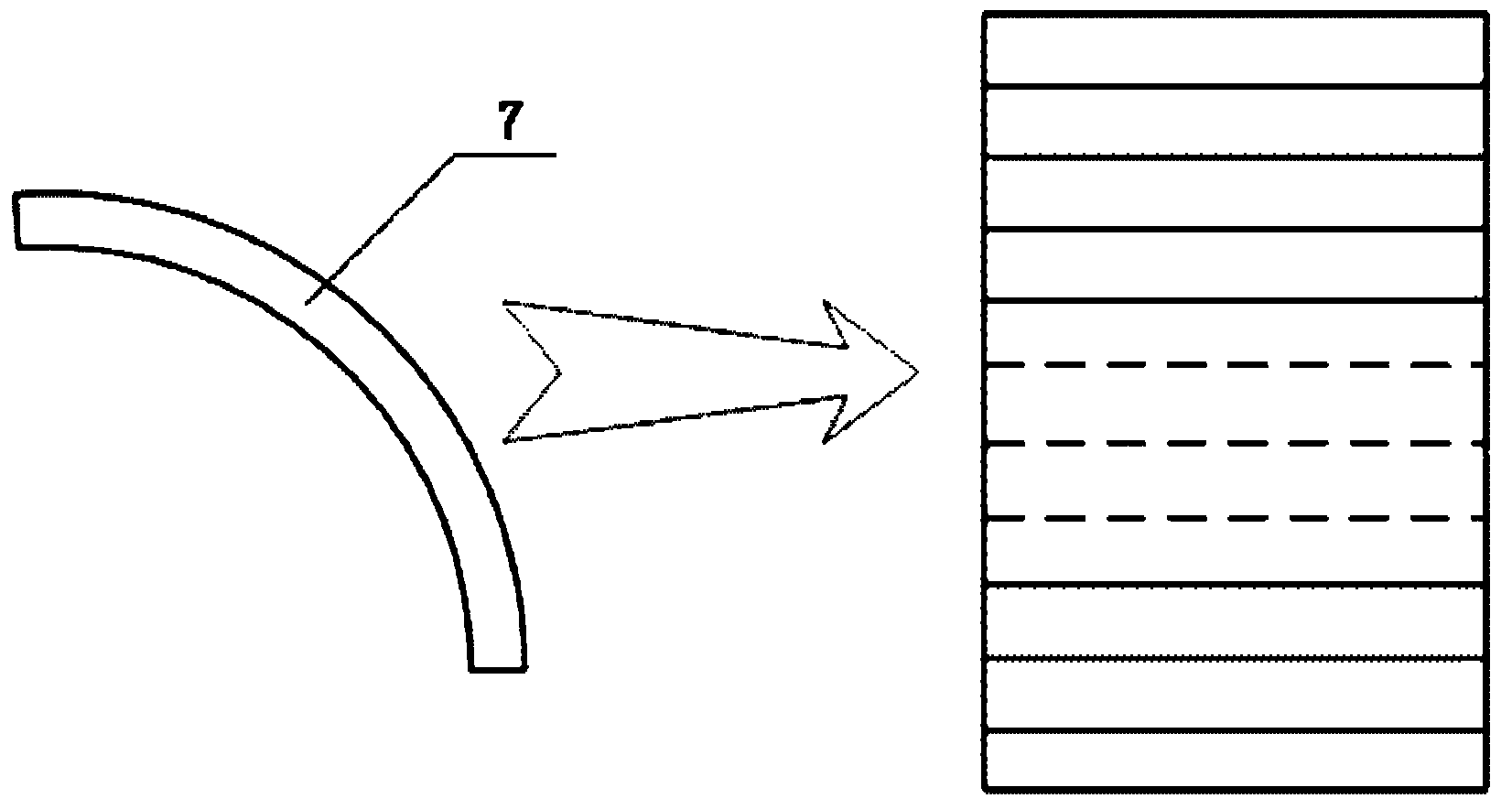

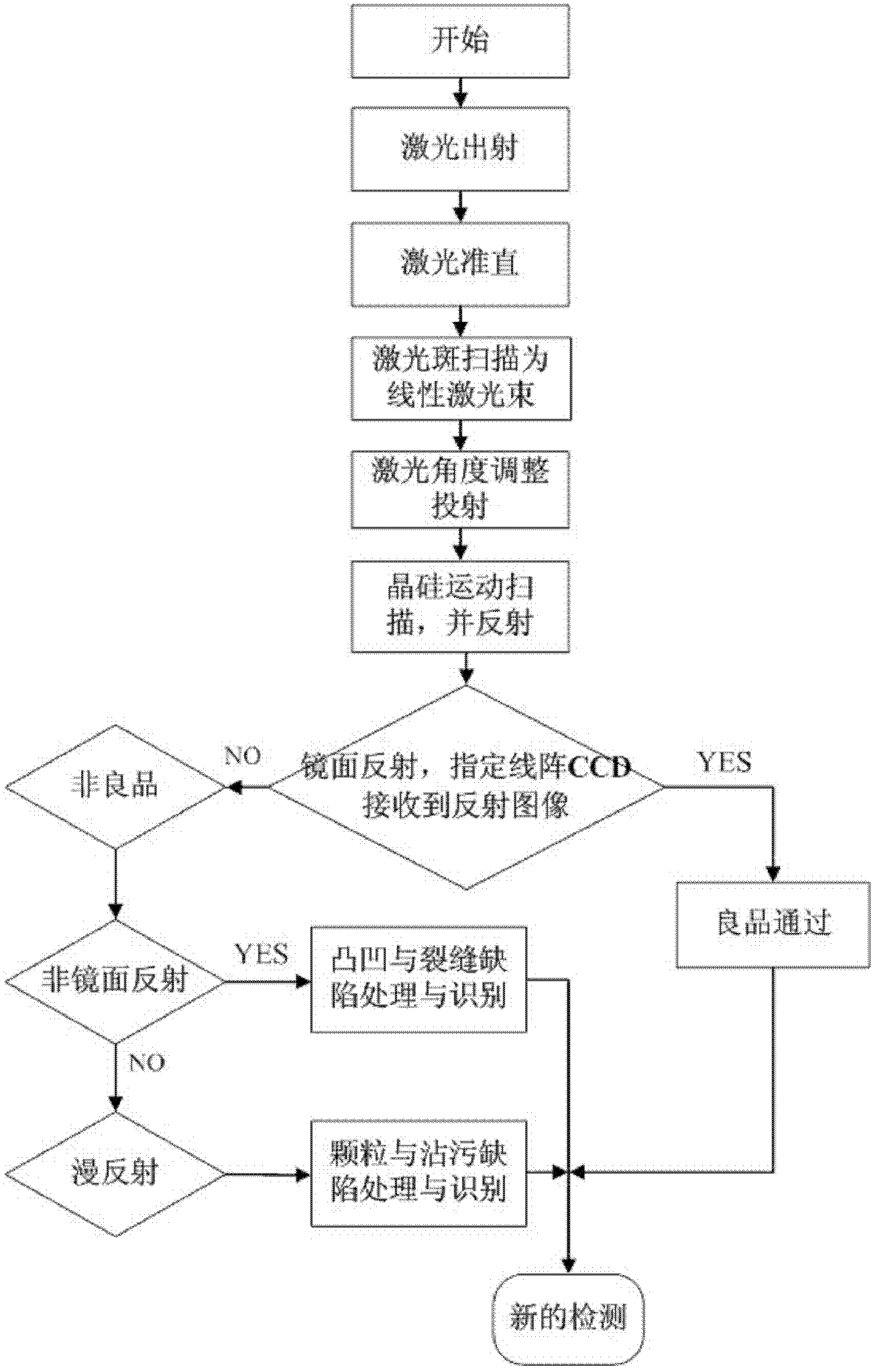

[0032] refer to Figure 1 ~ Figure 3 A surface defect detection system for a polished crystal silicon wafer includes a laser module, an optical scanning module, a pattern detection module, a movement module for a polished crystal silicon wafer, and a display and control module. The laser module is connected with the optical scanning module, the optical scanning module is fixed on the side above the polished crystal silicon wafer to be detected, and the pattern detection module is fixed on the polished silicon wafer to be detected with a π / 2 radian relative to the The other side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com