Preparation method of large-area sequential controllable surface-enhanced Raman active substrate

A surface-enhanced Raman and active substrate technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of small substrate area, poor substrate repeatability, complex process, etc., achieve orderly and controllable substrate structure, and prepare substrates. Large area and good substrate repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

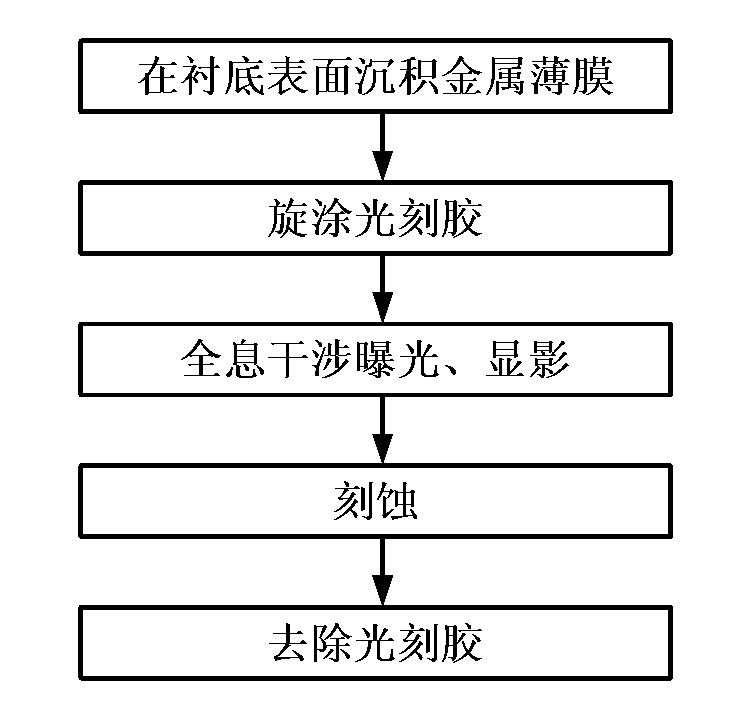

[0020] see figure 1 As shown, the present invention provides a method for preparing a large-area ordered and controllable surface-enhanced Raman active substrate, comprising the following steps:

[0021] Step 1: Take a substrate, the material of which is glass, single crystal Si, sapphire, GaAs or GaN. The taken substrate is cleaned to remove surface impurities. For glass, sapphire, GaAs or GaN substrates, first scrub the polished surface of the substrate with cotton soaked in acetone; place it in acetone and absolute ethanol for 5 minutes (temperature 55°C); Rinse with water 40 times; then soak in acetone and dry with nitrogen to complete the cleaning of the glass substrate. For a single crystal Si substrate, first scrub the polished surface of the substrate with cotton soaked in acetone; place it in acetone and absolute ethanol in sequence for 5 minutes (temperature 55 ° C); rinse with deionized water 40 times; Boil it with a mixed solution of sulfuric acid and hydrogen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com