Ferroalloy mine heat furnace system with waste heat power generation system

A waste heat power generation and submerged arc furnace technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of waste heat resources, thermal pollution of workers' production environment, etc., and achieve the effect of saving secondary energy and reducing thermal pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

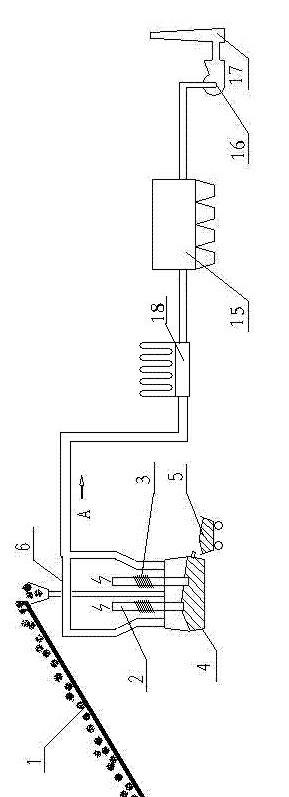

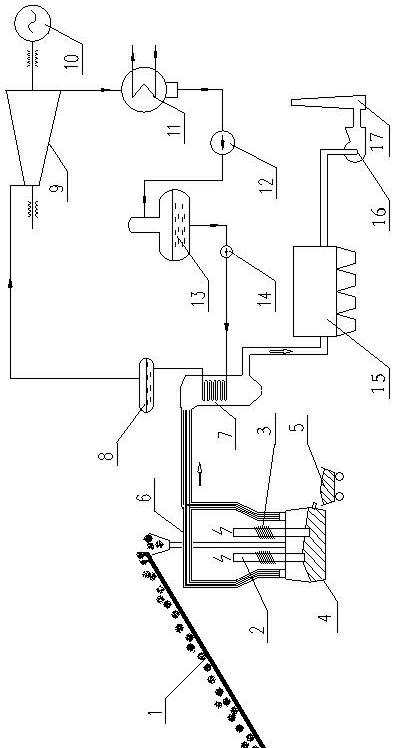

Embodiment 1

[0018] like figure 2 As shown, the ferroalloy submerged arc furnace system with waste heat power generation system in this embodiment includes: feeding system 1, electrode holding, pressing and lifting system 2, electrode water cooling system 3, submerged arc furnace body 4, and tapping system 5 , waste heat power generation system and dust removal system, etc. The waste heat power generation system includes: high temperature flue 6, waste heat boiler 7, power generation system and water treatment system, etc. The power generation system includes a steam turbine 9 and a generator 10 , the water treatment system includes a condenser 11 , a condensed water pump 12 , a deaerator 13 and a feed water pump 14 ; the dust removal system includes a dust removal fan 16 and a discharge chimney 17 . The high-temperature flue 6 can adopt an inner heat-insulation flue in the form of inner heat preservation, a heat-resistant stainless steel flue or a vaporization cooling flue that adopts a...

Embodiment 2

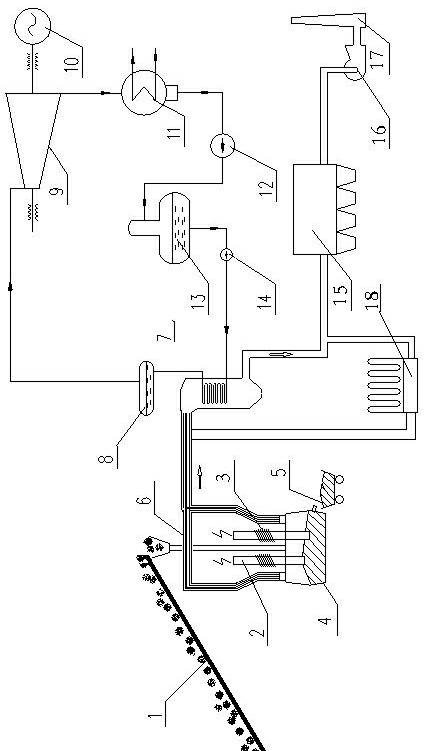

[0021] like image 3 As shown, the composition and structural form of the ferroalloy submerged arc furnace system in this embodiment are basically the same as in embodiment 1, the difference is that a surface cooler 18 is also arranged in the ferroalloy submerged arc furnace system in this embodiment, the The surface cooler 18 is arranged in parallel with the waste heat power generation system as a bypass of the waste heat power generation system between the high temperature flue gas pipeline 6 and the dust removal system. This system retains the surface cooler 18 in the flue gas dedusting system of the submerged arc furnace originally designed, so that the waste heat boiler 7 acts as a parallel bypass of the surface cooler 18, and when the waste heat boiler 7 is running, the surface cooler is closed by operating the flue valve 18 this branch and open the waste heat boiler 7 this branch, the heat of the high-temperature flue gas of the submerged arc furnace is replaced from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com