Special primer for heavy-duty machinery

A technology of heavy machinery and primer, applied in the direction of coating, anti-corrosion coating, epoxy resin coating, etc., can solve the problems of low cost performance of pollution, anti-corrosion and insufficient performance of supporting construction, etc. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

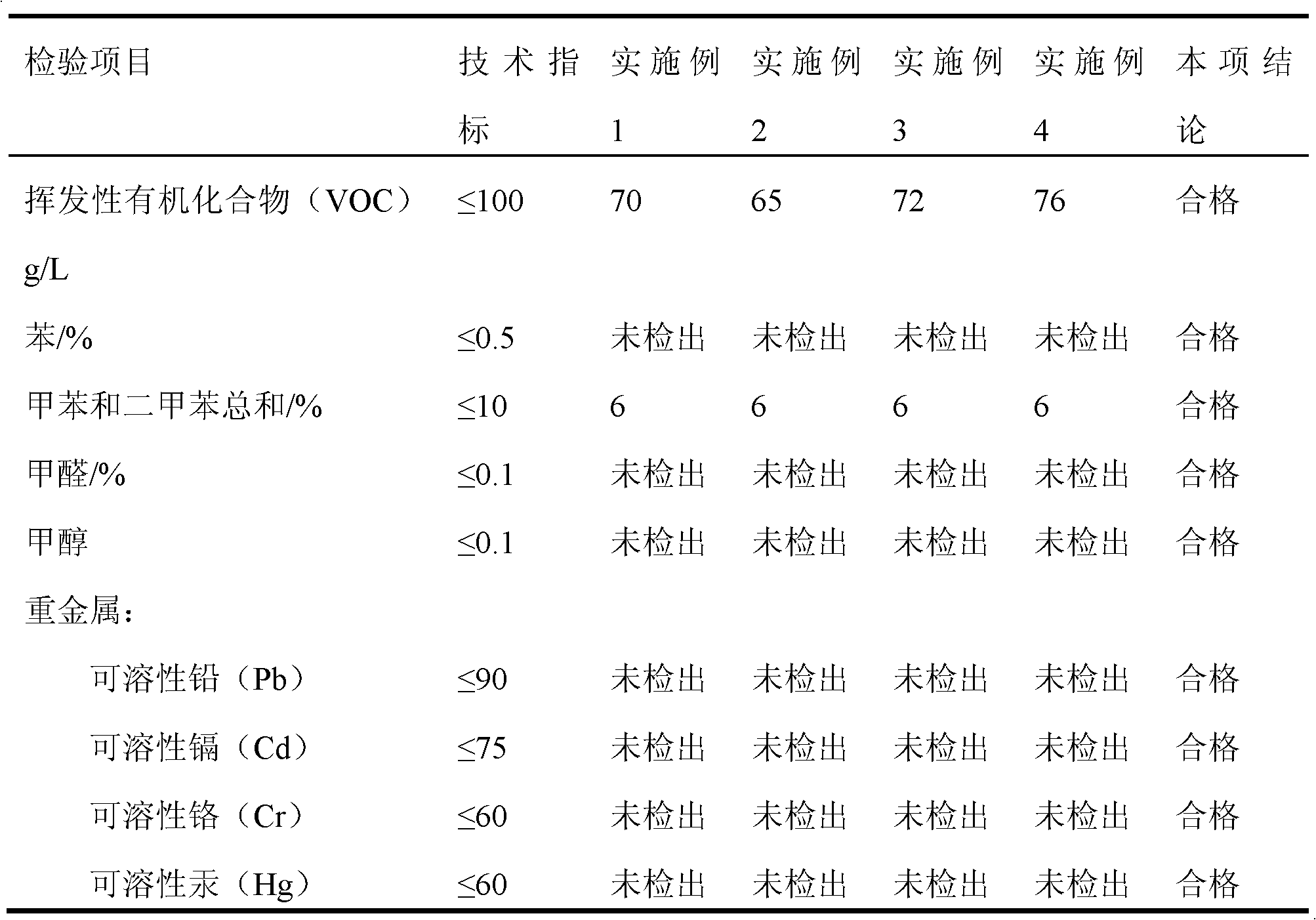

Examples

Embodiment 1

[0027] Put 450g of bisphenol A into the dissolution kettle, then pass through 900g of epichlorohydrin, heat the jacket with water vapor and raise the temperature to above 70°C to dissolve. After completely dissolving, use a pump to press into a stirred reactor, use quaternary ammonium salt as a catalyst, slowly add 265mL of NaOH solution with a mass fraction of 30%, and control the reaction temperature during this process to be 50-55°C. After the dropwise addition of the NaOH solution is completed, raise the temperature to 70-75°C and keep for 1 hour, then raise the temperature to 100°C and reduce the pressure to 94.66kPa, and recover excess epichlorohydrin for recycling. Then add methyl isobutyl ketone (MIBK) which is 20% by mass of the resin liquid (previously prepared mixture) to dissolve the resin liquid, leave to stand and separate after stirring. Add the resin liquid and methyl isobutyl ketone solution in the upper layer into the water separator, stir, heat, maintain, st...

Embodiment 2

[0030]Put 500g of bisphenol A into the dissolution kettle, then pass through 1200g of epichlorohydrin, heat the jacket with water vapor and raise the temperature to above 70°C to dissolve. After completely dissolving, pump it into a stirred reactor, use quaternary ammonium salt as a catalyst, slowly add 260mL NaOH solution with a mass fraction of 30%, and control the reaction temperature during this process to 50-55°C. After the dropwise addition of the NaOH solution is completed, raise the temperature to 70-75°C and keep for 1 hour, then raise the temperature to 100°C and reduce the pressure to 94.66kPa, and recover excess epichlorohydrin for recycling. Then add methyl isobutyl ketone (MIBK) which is 25% by mass of the resin liquid (previously prepared mixture) to dissolve the resin liquid, leave to stand and separate after stirring. Add the resin liquid and methyl isobutyl ketone solution in the upper layer into the water separator, stir, heat, maintain, stand still and remo...

Embodiment 3

[0033] Put 400g of bisphenol A into the dissolution kettle, then pass through 850g of epichlorohydrin, heat the jacket with water vapor and raise the temperature to above 70°C to dissolve. After completely dissolving, use a pump to press into a stirred reactor, use quaternary ammonium salt as a catalyst, slowly add 250mL NaOH solution with a mass fraction of 30%, and control the reaction temperature during this process to 50-55°C. After the dropwise addition of the NaOH solution is completed, raise the temperature to 70-75°C and keep for 1 hour, then raise the temperature to 100°C and reduce the pressure to 94.66kPa, and recover excess epichlorohydrin for recycling. Then add methyl isobutyl ketone (MIBK) which is 20% by mass of the resin liquid (previously prepared mixture) to dissolve the resin liquid, leave to stand and separate after stirring. Add the resin liquid and methyl isobutyl ketone solution in the upper layer into the water separator, stir, heat, maintain, stand st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com