Matrix type sapphire substrate and preparation method thereof

A sapphire substrate and matrix technology, applied in the field of sapphire, can solve the problems of increased production cost, inability to recycle, waste of resources, etc., and achieve the effects of improving chip heat dissipation, saving costs, and reducing damage to the backside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

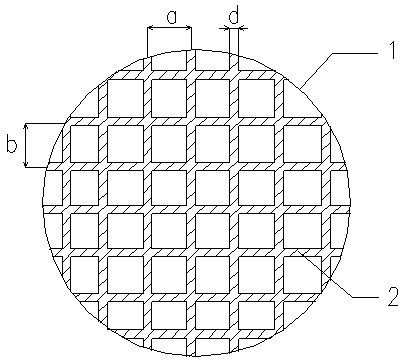

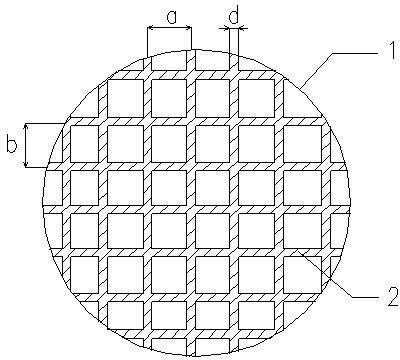

[0054] see figure 1 , a kind of matrix type sapphire substrate that the present invention relates to, comprises substrate body 1, and the material of described substrate body 1 is the cutting sheet of sapphire, grinding sheet or polishing sheet, and the thickness of described substrate body 1 is 200um~ 1200um, the surface of the substrate body 1 is provided with criss-cross grooves 2, the depth of the grooves 2 is 1nm~500um, the width d of the grooves 2 is 0.1nm~5.0mm, the vertical and horizontal The staggered grooves 2 divide the surface of the substrate body 1 into a matrix pattern, the distance a between the longitudinal grooves 2 is 1 mm to 50 mm, and the distance b between the horizontal grooves 2 is 1 mm to 50 mm. 1 can be in any shape. As a preference, the shape of the substrate body 1 is circular, and the diameter of the circular substrate body 1 is 25-300 mm. As a preference, the substrate body 1 The shape of the substrate body 1 is square, and the side length of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com