MOS element manufacturing method for reducing damage caused by hot carriers injection

A MOS device, injection damage technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as threshold voltage degradation, MOS device failure, energy bond breakage, etc., to reduce damage, reduce gate The effect of polar current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

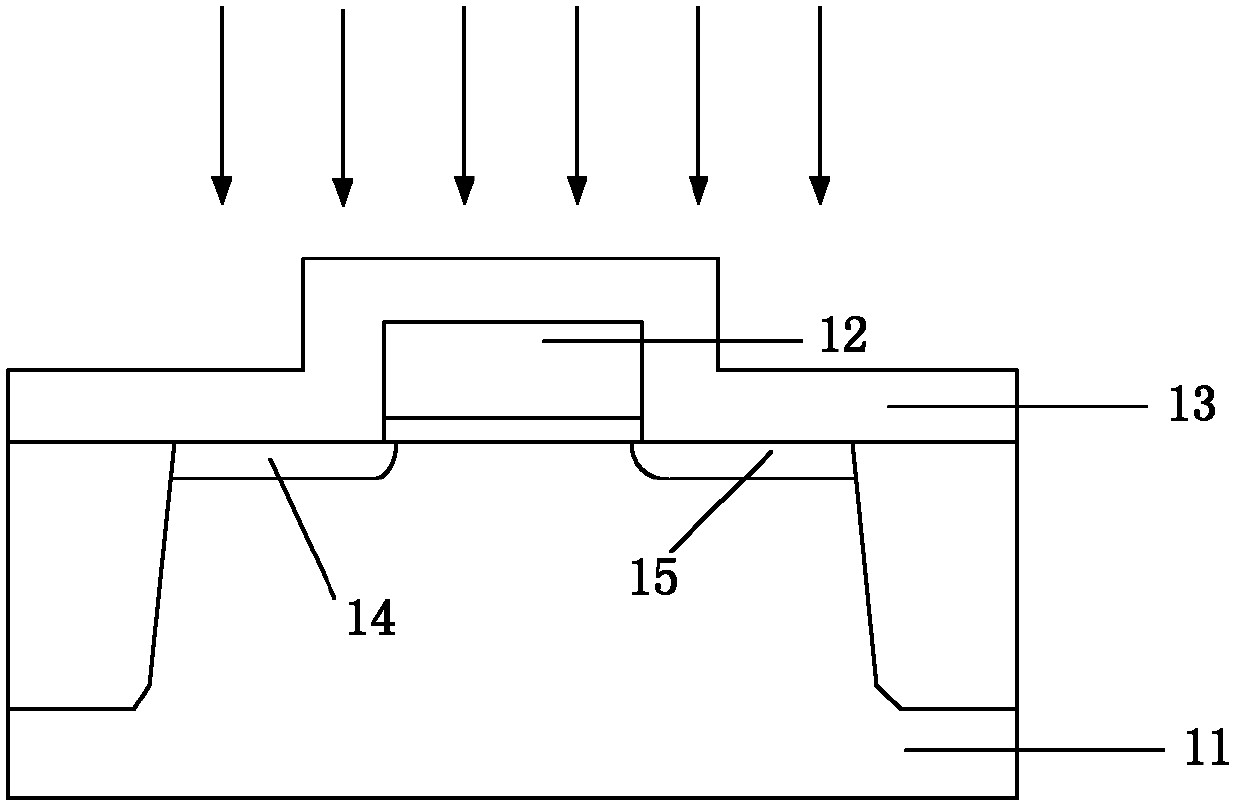

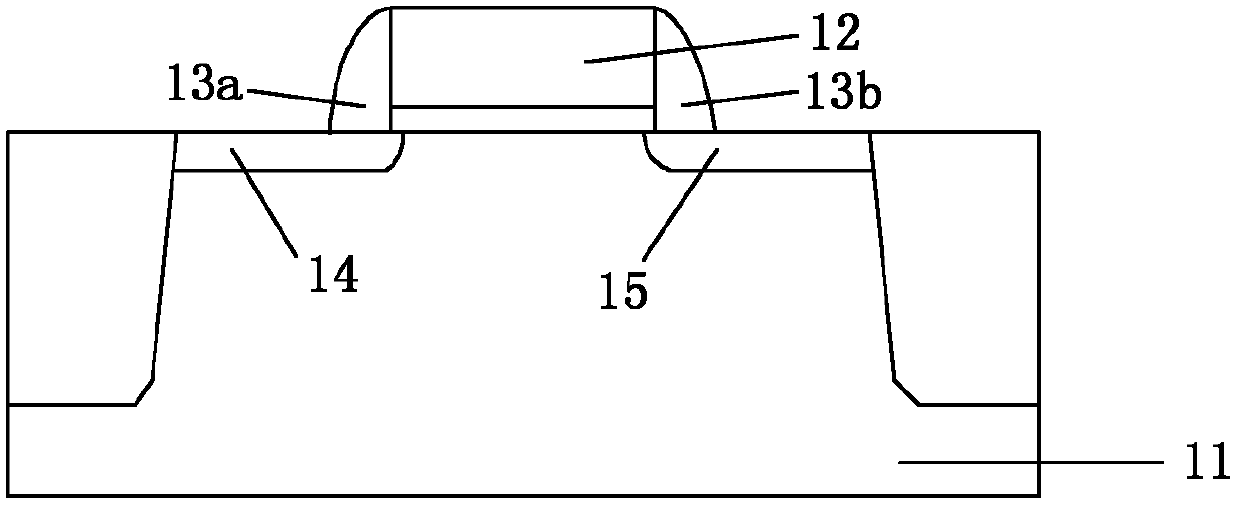

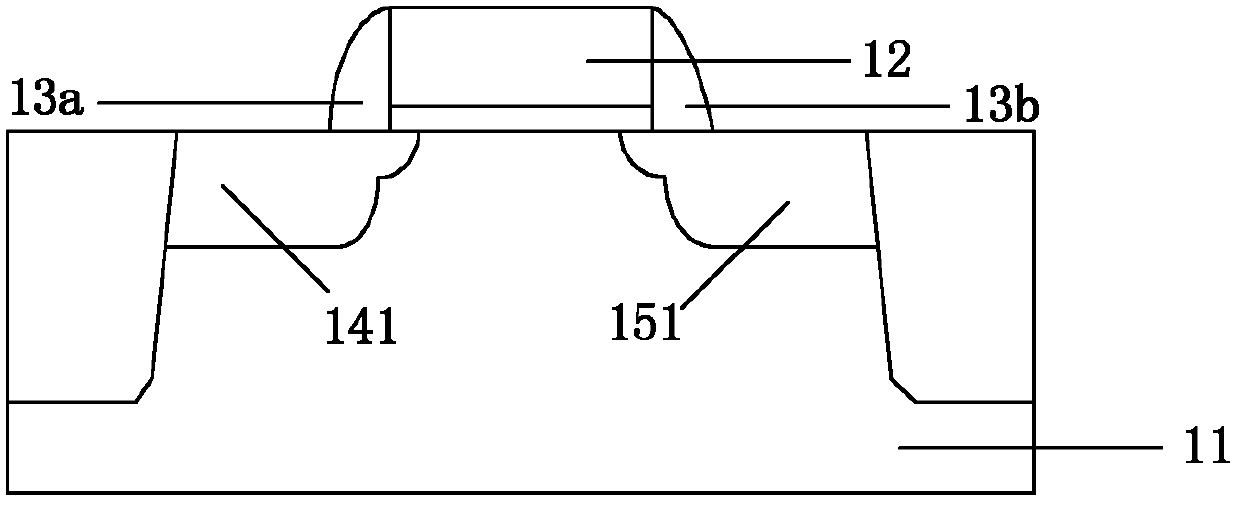

[0014] Please refer to Figure 2A-Figure 2F , taking the NMOS device in the CMOS transistor process as an example, the MOS device manufacturing method for reducing hot carrier injection damage of the present invention includes:

[0015] First, if Figure 2A As shown, a gate structure 22 is formed on a substrate 21, and the substrate 21 includes a source region and a drain region. The source region refers to the source extension region and the source heavily doped region to be formed later region, similarly, the drain region refers to the region where the drain extension region and the heavily doped drain region will be formed subsequently;

[0016] Then, if Figure 2B As shown, the gate structure 22 is used as a mask, and the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com