Extreme-ultraviolet-projection photoetching objective lens

A projection light, extreme ultraviolet technology, applied in microlithography exposure equipment, optics, optical components, etc., can solve the problems of reduced field of view lithography performance, reduced optical modulation transfer function, reduced lithography performance, etc., to achieve excellent imaging. quality, improve lithography resolution, reduce the difficulty of processing and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

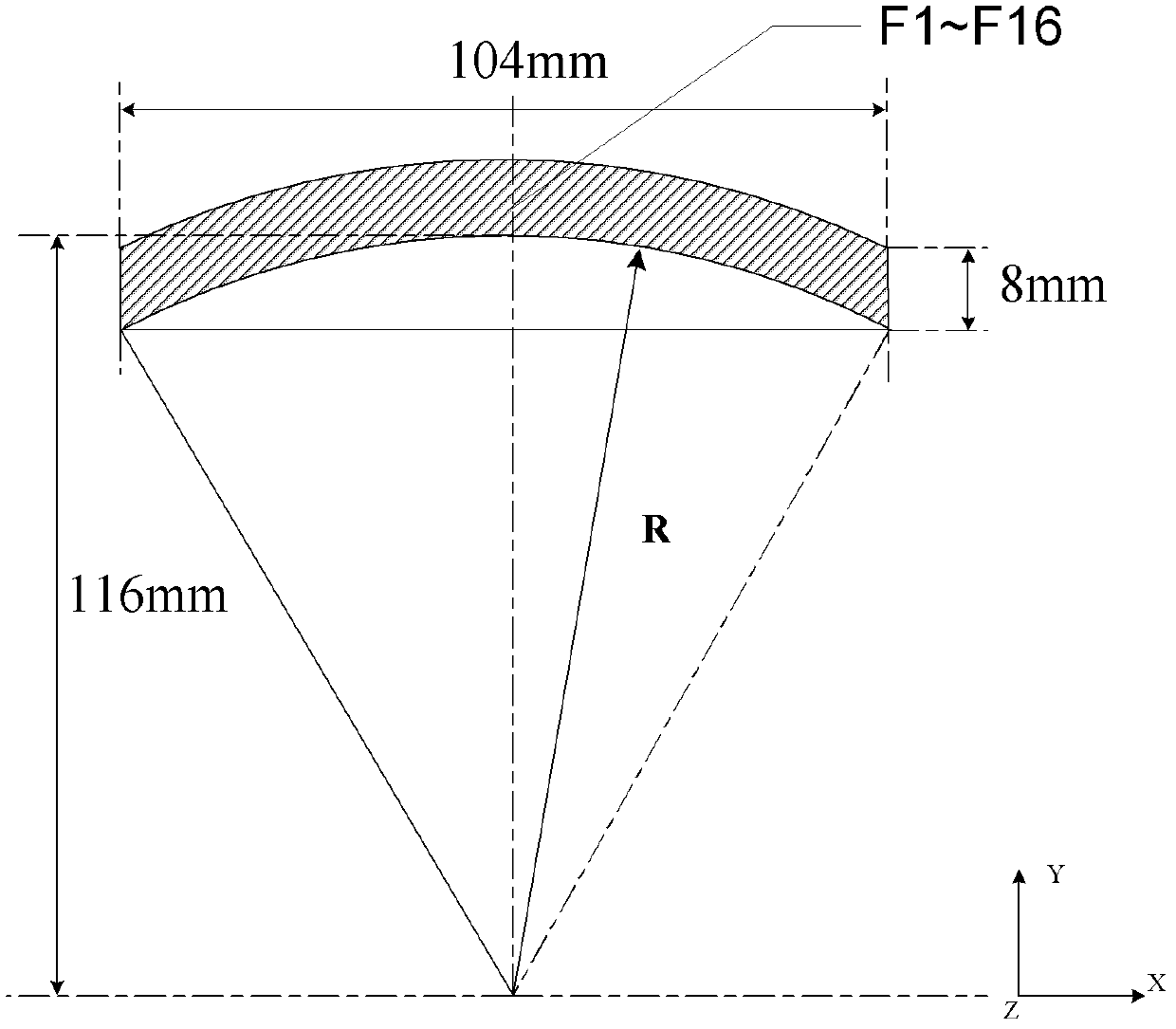

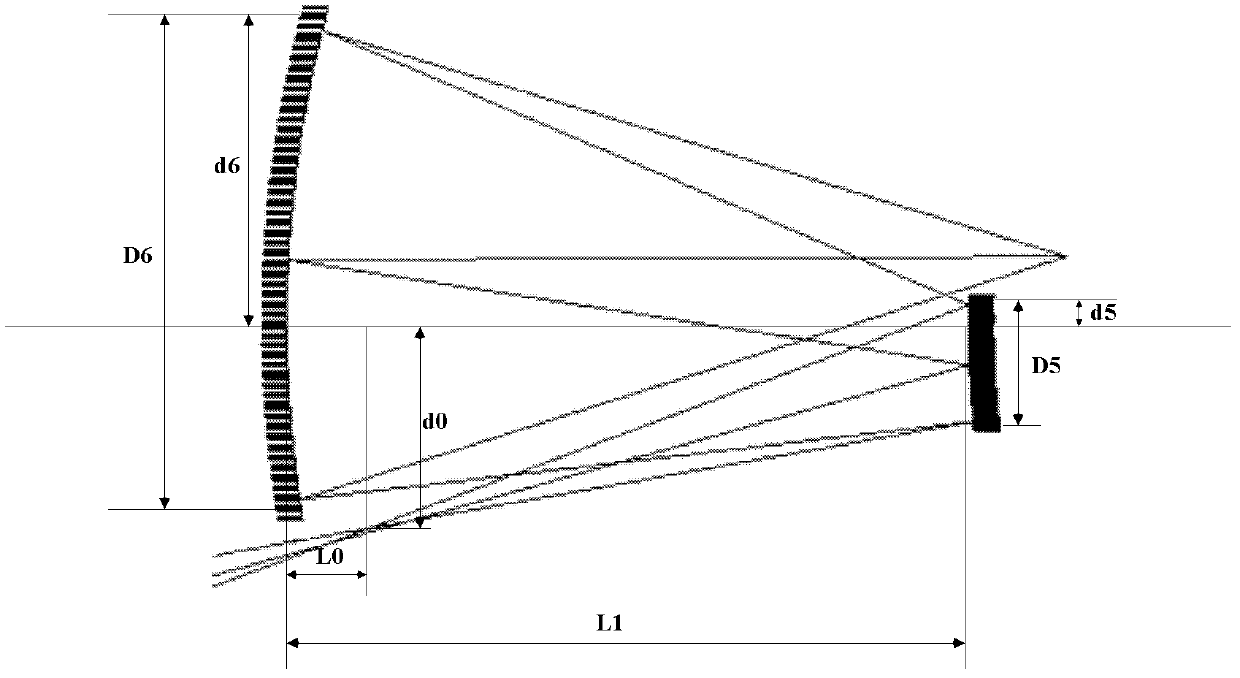

[0052] The extreme ultraviolet projection lithography objective lens of the present invention includes a first mirror group and a second mirror group, and the first mirror group includes a circular diaphragm and four reflecting mirrors, wherein the four reflecting mirrors are respectively the first reflecting mirror M1 and the second reflecting mirror. Two reflecting mirrors M2, the third reflecting mirror M3 and the fourth reflecting mirror M4, the second mirror group includes two reflecting mirrors, which are respectively the fifth reflecting mirror M5 and the sixth reflecting mirror M6; The positional relationship between the circular diaphragms is: first mirror M1, circular diaphragm, second mirror M2, third mirror M3, fourth mirror M4, fifth mirror M5, sixth mirror M6 .

[0053] Table 1 shows the specific design parameters of each lens in this embodiment; a negative sign in front of the radius value indicates that the center of curvature of the lens is located on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com