Thick steel plates for high heat input welding and production method thereof

A high-energy-input welding and manufacturing method technology, which is applied in the field of iron and steel metallurgy and iron and steel materials, can solve problems such as insufficient improvement of the toughness of the heat-affected zone of welding, and achieve the effect of improving the performance of high-energy-input welding and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

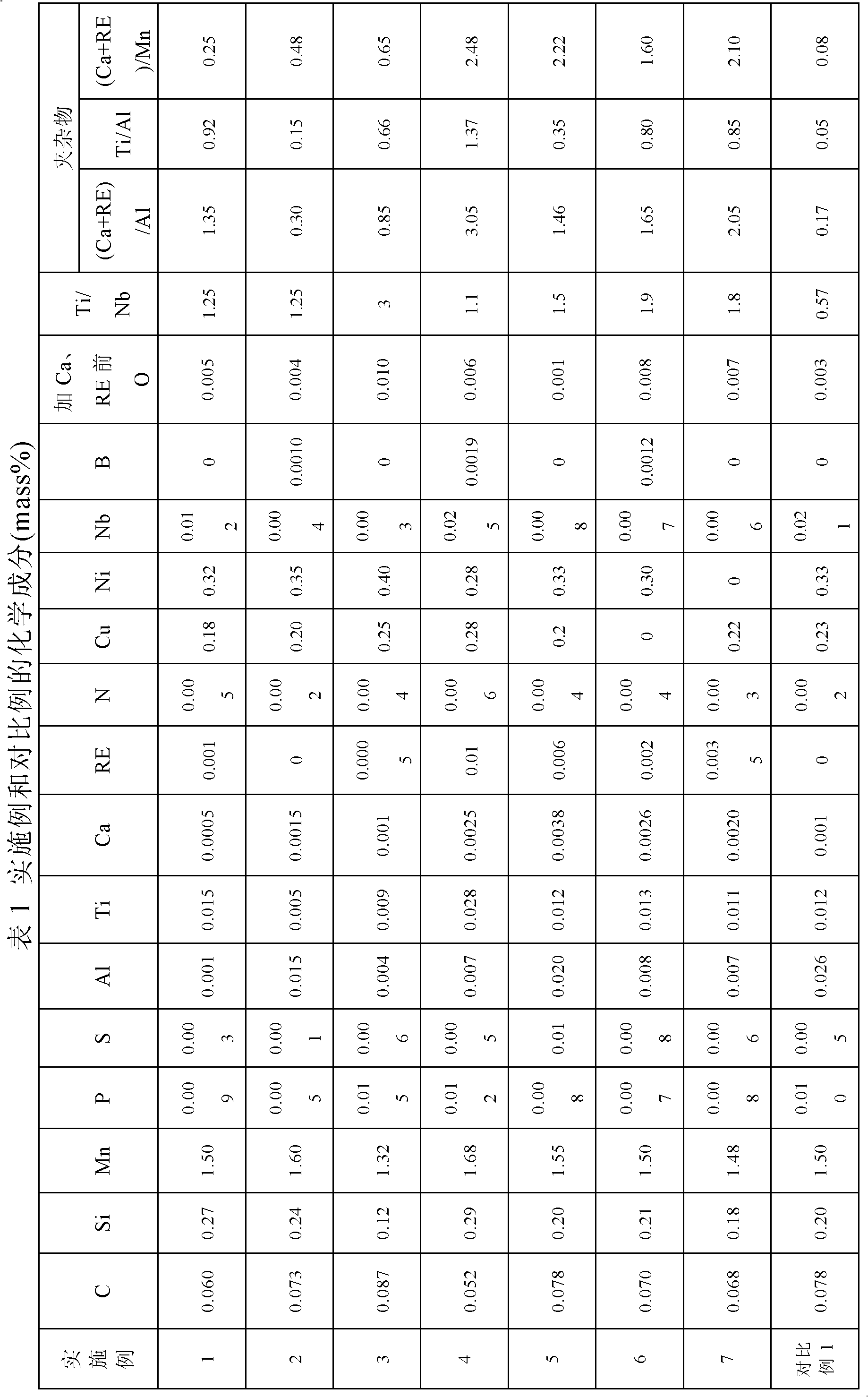

[0056] The present invention will be further described below in conjunction with embodiment.

[0057] In the embodiment of the present invention, the alloy composition in the molten steel is adjusted during the refining process. And deoxidize by adding alloys of corresponding elements in the order of Si, Mn, Al, Ti. While ensuring the composition of the alloy, add Fe at the end 2 o 3 powder, and CaSi alloy and / or rare earth ferrosilicon. The CaSi alloy contains 30% Ca, the balance is Si, and the particle size is 0.1-5mm. The rare earth ferrosilicon contains 30.6% RE, 47.4% Si, the balance is Fe, and the particle size is 0.1-5mm.

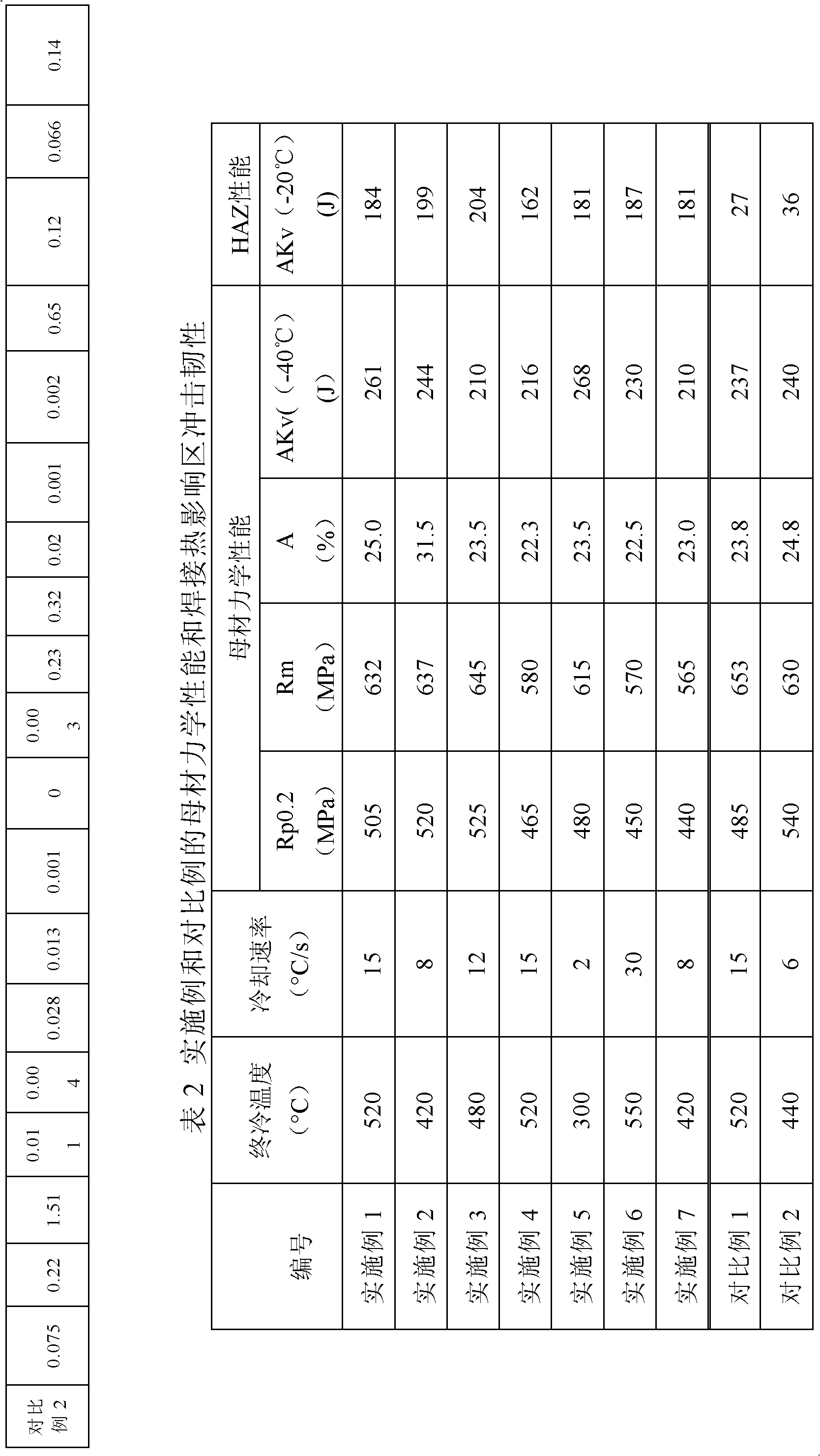

[0058] Then the billet is heated to 1250°C, the initial rolling temperature is 1000-1150°C, and the cumulative reduction rate is 50%; the finish rolling temperature is 700-850°C, and the cumulative reduction rate is 67%; The cooling rate of °C / s is water-cooled to a final cooling temperature of 300-550 °C.

[0059] The welding thermal simulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com