Quick-dry thin acrylic-acid protective coating and HDPE (high-density polyethylene) self-adhesive film waterproof roll protective coating layer

A protective coating and protective coating technology, applied in the field of chemical materials, can solve the problems of poor construction quality, short building life, damage to waterproof structures, etc., and achieve the effects of high production efficiency, low overall cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

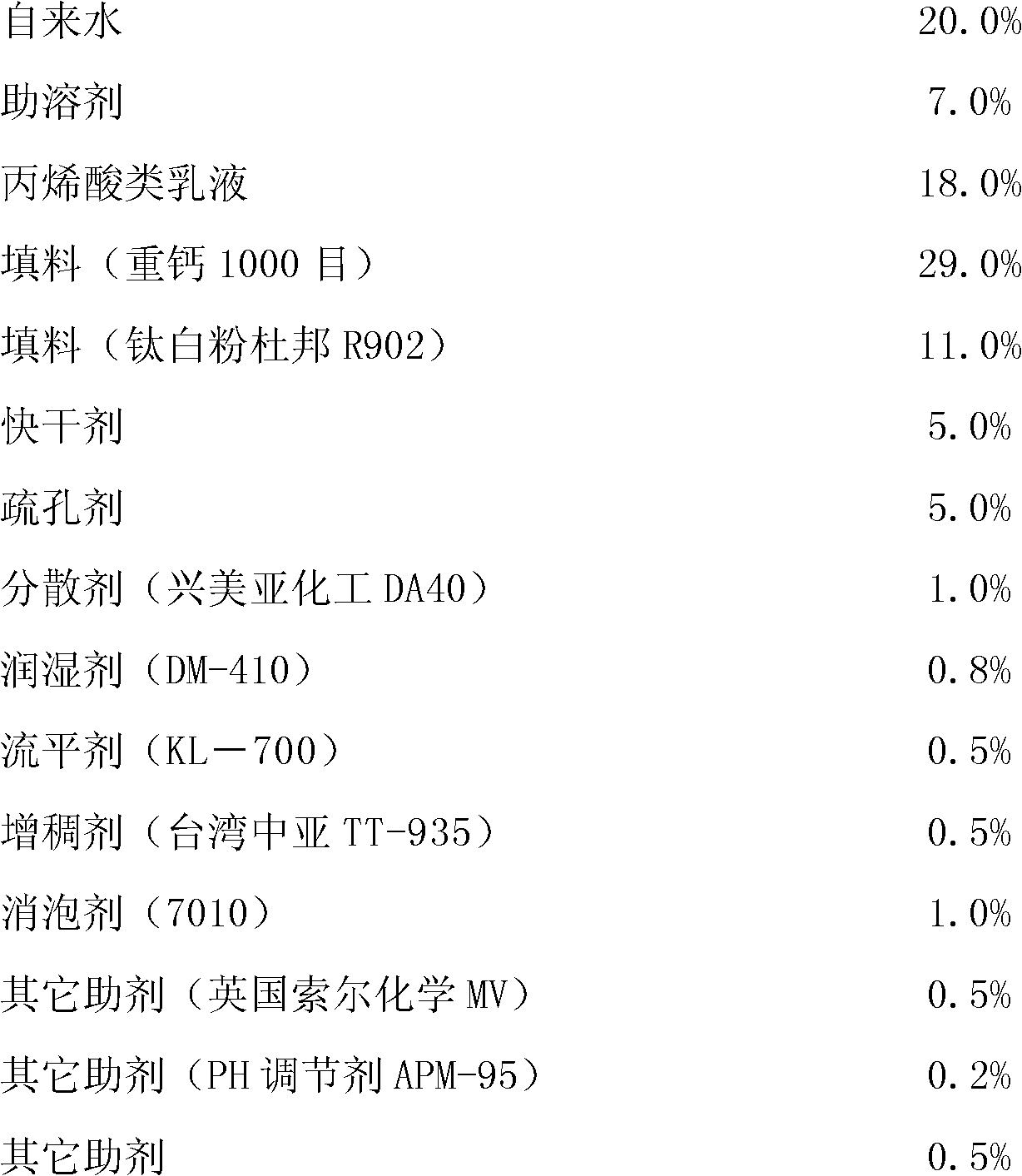

[0064] 1. Formulation of quick-drying and thin-coating acrylic protective coating

[0065]

[0066] 2. Preparation method of quick-drying and thin-coating type acrylic protective coating

[0067] 1) Accurately weigh tap water according to the formula, add it to the dispersion tank, stir at about 100 rpm;

[0068] 2) Accurately weigh the dispersant, wetting agent and defoamer, add them to the dispersing tank, stir at a low speed (100 rpm) for 3 minutes, and stir evenly;

[0069] 3) Increase the stirring speed to 200 rpm, slowly and evenly add the accurately weighed pigments, fillers, and anti-fungal agents, and add them in 10-15 minutes, increase the stirring speed to 960 rpm, and carry out high-speed dispersion for 2 hours. Degree, qualified spare.

[0070] 4) Accurately weigh the emulsion and porosity agent, then slowly and evenly add it to the paint mixing tank, the feeding is completed in 5-8 minutes, disperse at a low speed (200 rpm) for 5 minutes, and stir evenly;

...

Embodiment 2

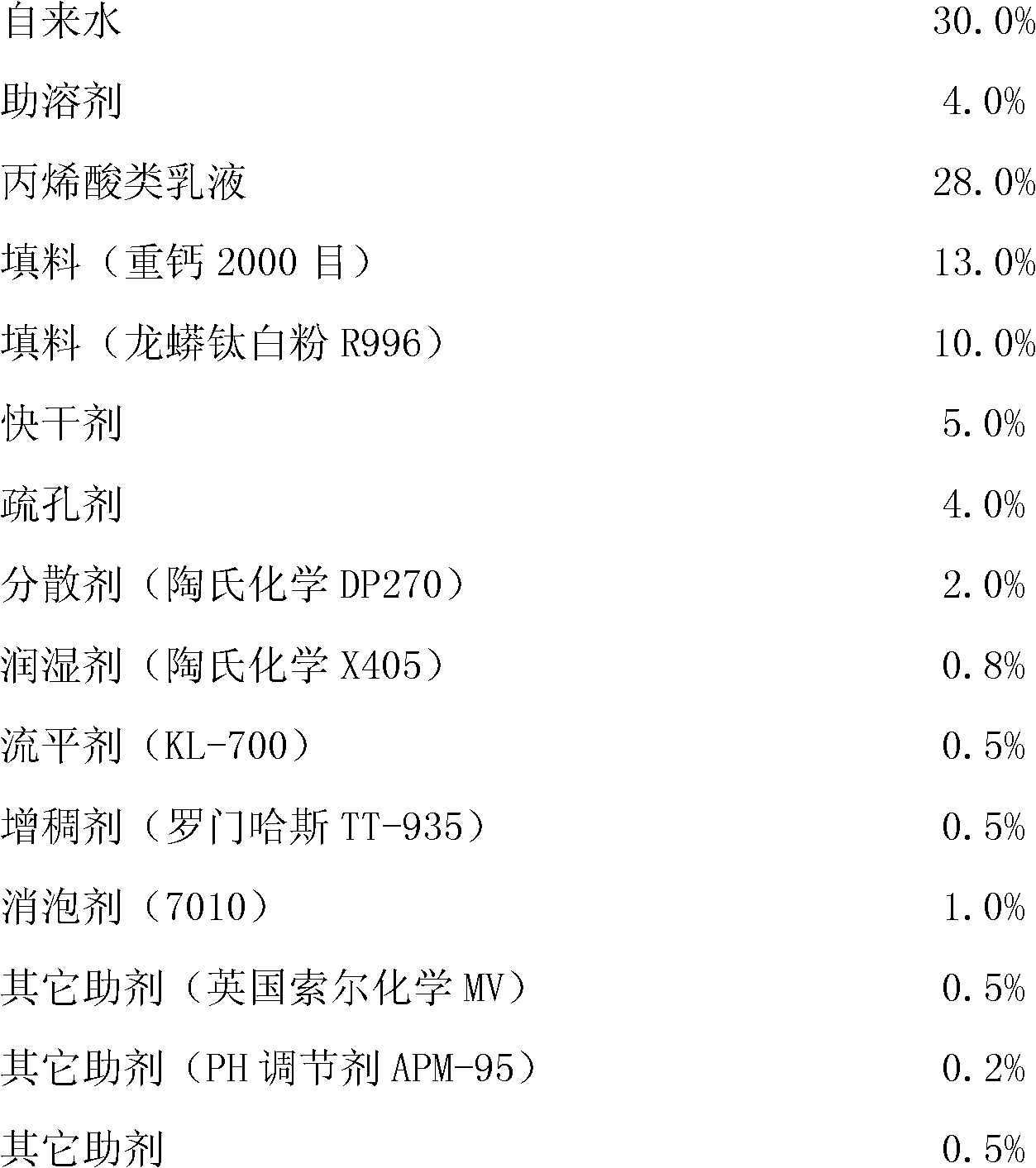

[0079] 1. Formulation of quick-drying and thin-coating acrylic protective coating

[0080]

[0081] 2. Preparation method of quick-drying and thin-coating type acrylic protective coating

[0082] The preparation method is the same as in Example 1.

[0083] 3. Forming process of HDPE self-adhesive film waterproof membrane protective coating

[0084] The molding process is the same as in Example 1.

Embodiment 3

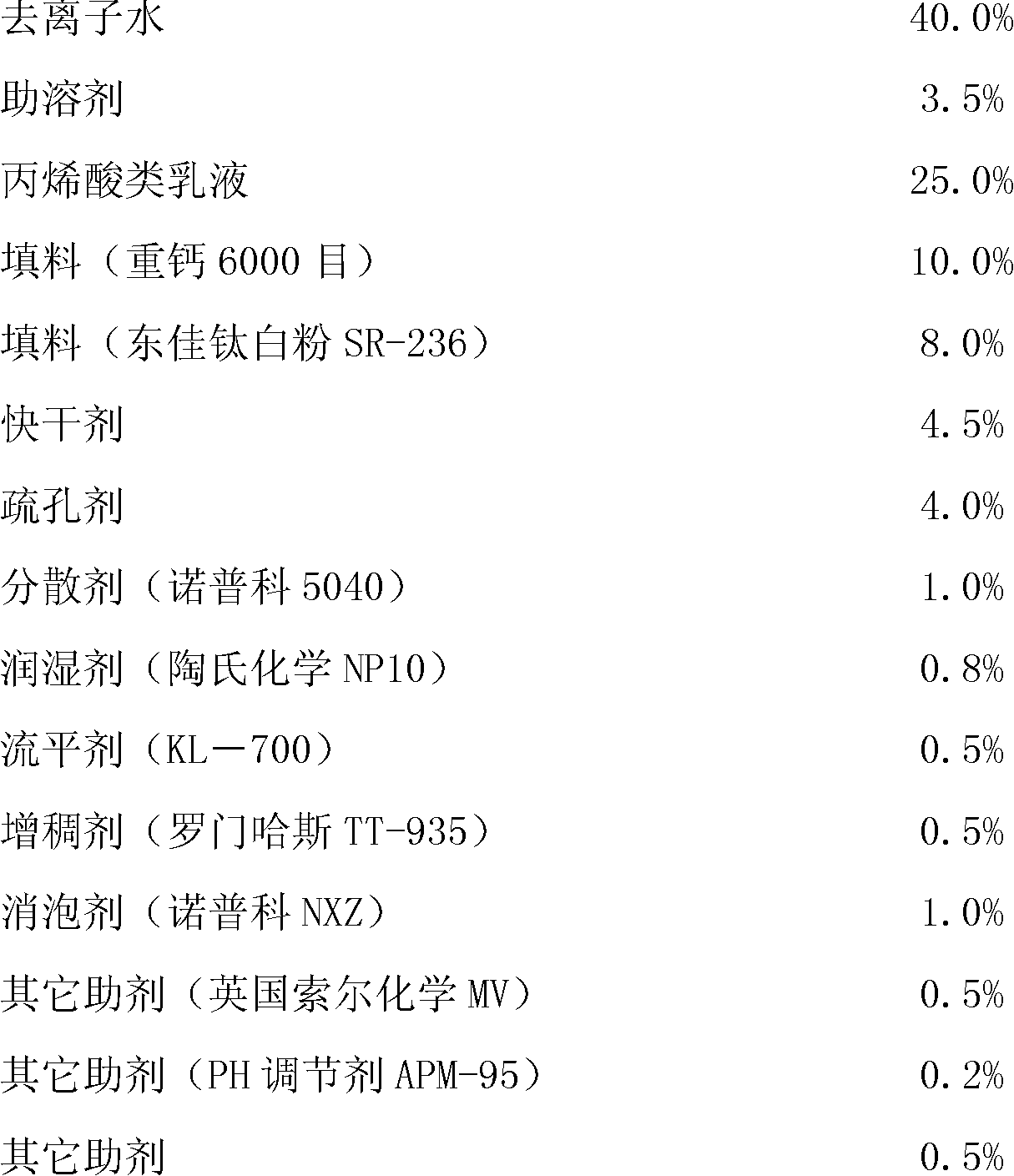

[0086] 1. Formulation of quick-drying and thin-coating acrylic protective coating

[0087]

[0088] 2. Preparation method of quick-drying and thin-coating type acrylic protective coating

[0089] The preparation method is the same as in Example 1.

[0090] 3. Forming process of HDPE self-adhesive film waterproof membrane protective coating

[0091] The molding process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com