Ecological floating island phosphorous removal composite medium and preparation method thereof

A composite matrix, ecological floating island technology, applied in chemical instruments and methods, biological treatment devices, biological water/sewage treatment, etc., can solve problems such as poor phosphorus removal effect in repairing river water bodies, and save raw material costs and adsorption capacity. Reduced, good pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

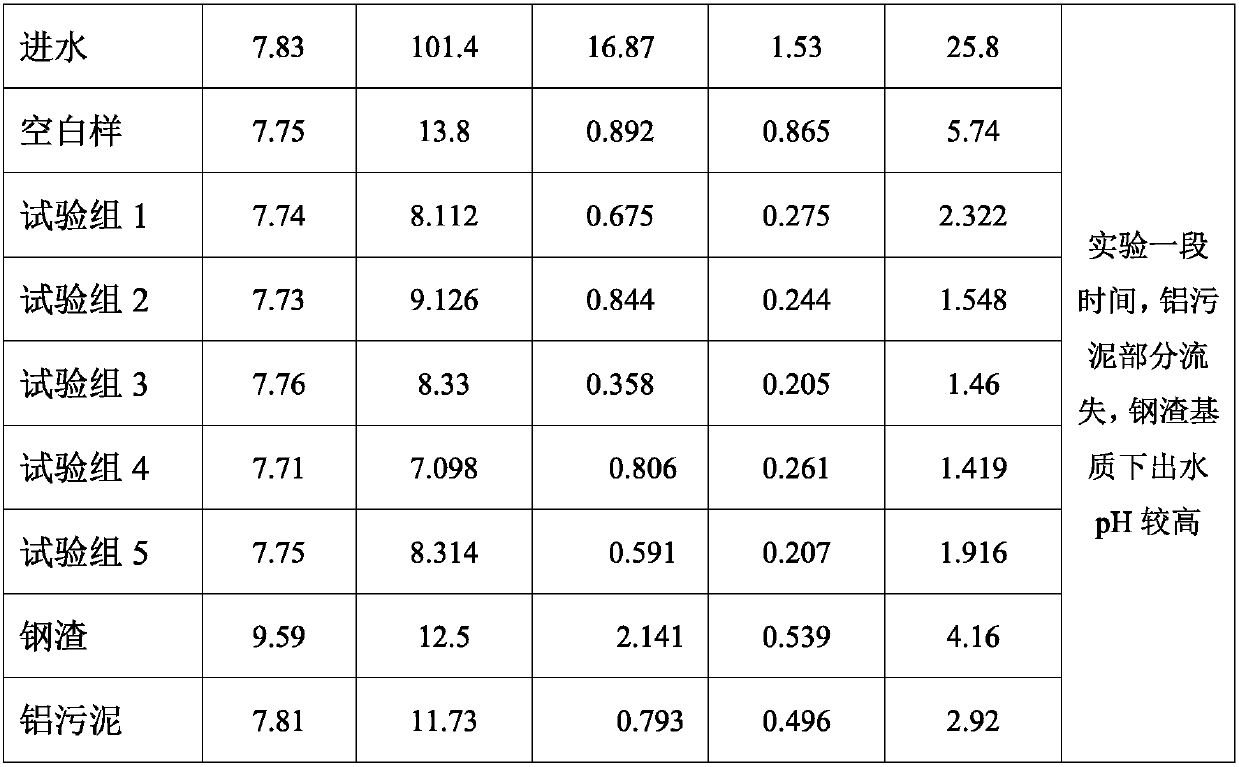

Examples

Embodiment 1

[0030] A method for preparing the ecological floating island phosphorus removal composite matrix, the specific preparation process is as follows:

[0031] S1, aluminum sludge, steel slag and coconut shell fiber are carried out drying pretreatment respectively, mix after being ground into powder and make aluminum sludge powder, steel slag powder and coconut shell fiber powder;

[0032] S2. Take by weight percentage 40% of aluminum sludge powder, 20% of steel slag powder, 20% of coconut fiber powder, 10% of binder and 10% of starch prepared in step S1 for subsequent use;

[0033] S3, mixing the aluminum sludge powder, steel slag powder and coconut fiber powder taken in step S2 to obtain the first mixed powder;

[0034] S4. Add the binder and starch weighed in step S2 to the first mixed powder prepared in step S3, stir well, add water, granulate, heat treat at medium and high temperature, and cool to obtain an ecological floating island Use phosphorus removal composite matrix pa...

Embodiment 2

[0048] Embodiment 2 is another implementation method of embodiment 1, wherein the same technical solutions as in embodiment 1 are omitted and will not be repeated, and only the technical solutions different from embodiment 1 will be described below.

[0049] A method for preparing the ecological floating island phosphorus removal composite matrix, the specific preparation process is as follows:

[0050] S1, aluminum sludge, steel slag and coconut shell fiber are carried out drying pretreatment respectively, mix after being ground into powder and make aluminum sludge powder, steel slag powder and coconut shell fiber powder;

[0051] S2. Take by weight percentage 45% of aluminum sludge powder, 22% of steel slag powder, 15% of coconut fiber powder, 10% of binder and 8% of starch prepared in step S1 for subsequent use;

[0052] S3, mixing the aluminum sludge powder, steel slag powder and coconut fiber powder taken in step S2 to obtain the first mixed powder;

[0053] S4. Add the ...

Embodiment 3

[0063] Embodiment 3 is another implementation method of embodiment 1, wherein the same technical solutions as in embodiment 1 are omitted and will not be repeated, and only the technical solutions different from embodiment 1 will be described below.

[0064] A method for preparing the ecological floating island phosphorus removal composite matrix, the specific preparation process is as follows:

[0065] S1, aluminum sludge, steel slag and coconut shell fiber are carried out drying pretreatment respectively, mix after being ground into powder and make aluminum sludge powder, steel slag powder and coconut shell fiber powder;

[0066] S2. Take by weight percentage 50% of the aluminum sludge powder, 20% of the steel slag powder, 12% of the coconut fiber powder, 10% of the binder, and 8% of the starch prepared in the step S1 for subsequent use;

[0067] S3, mixing the aluminum sludge powder, steel slag powder and coconut fiber powder taken in step S2 to obtain the first mixed powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com