Black-increasing agent for high-temperature infrared-radiation energy-saving coating and preparation method of black-increasing agent

An energy-saving coating, high-temperature infrared technology, applied in coatings, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of unstable performance and high cost of infrared radiation coatings, achieve stable radiation rate, prolong service life, excellent durability abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

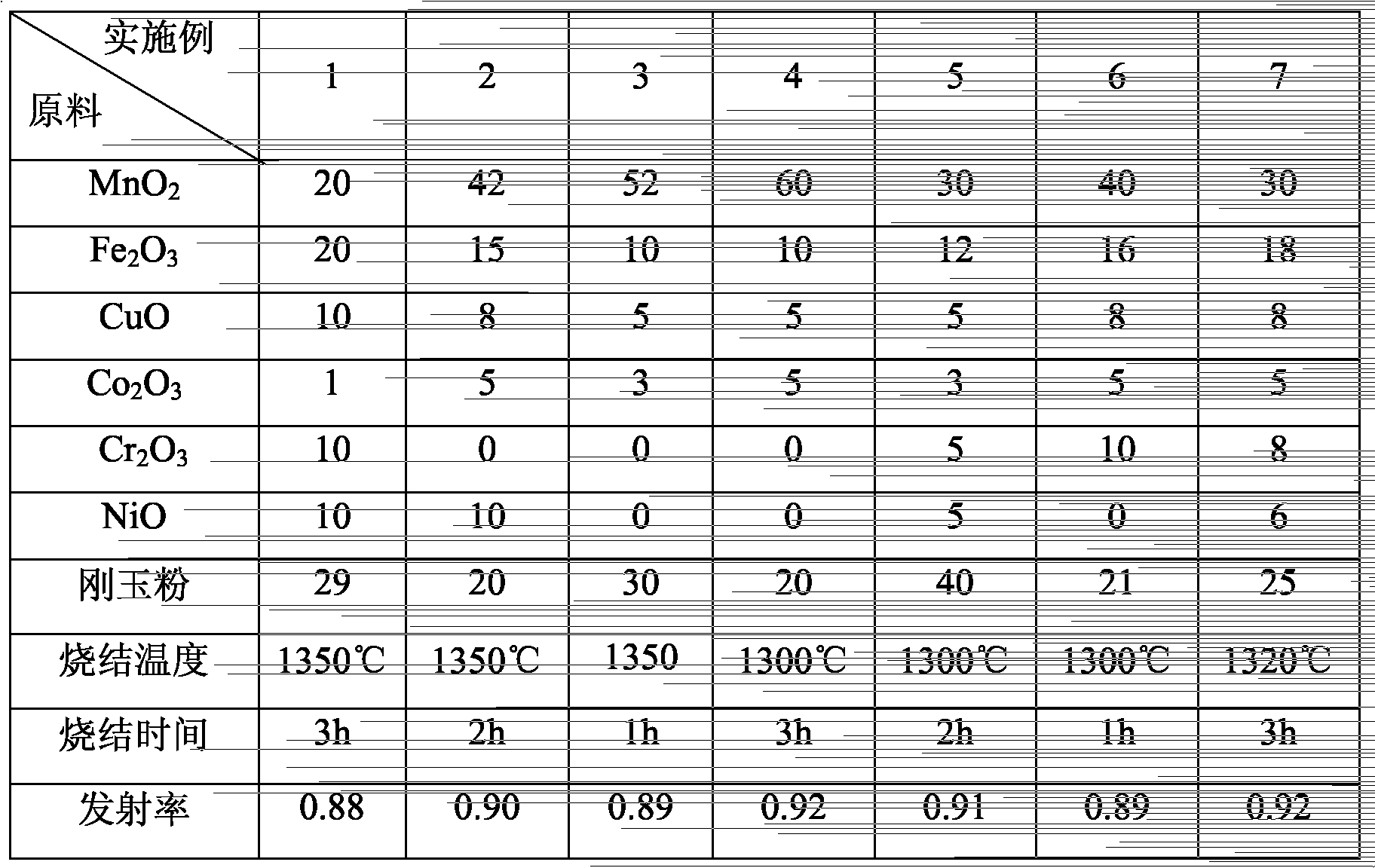

[0028] The blackening agent for high temperature infrared radiation energy-saving coatings is prepared from the following raw materials in percentage by weight:

[0029] MnO 2 : 20%, Fe 2 O 3 : 20%, CuO: 10%, Co 2 O 3 : 1%, Cr 2 O 3 : 10%,

[0030] NiO: 10%, black corundum powder: 29%.

[0031] According to needs, corundum powder can choose at least one of black corundum, brown corundum and white corundum

[0032] The preparation method of above-mentioned blackening agent, its steps are:

[0033] Step 1, the MnO 2 , Fe 2 O 3 , CuO, Co 2 O 3 , Cr 2 O 3 , NiO and corundum powder are mixed uniformly with a mixer in proportion, and then the mixture is pressed into a block.

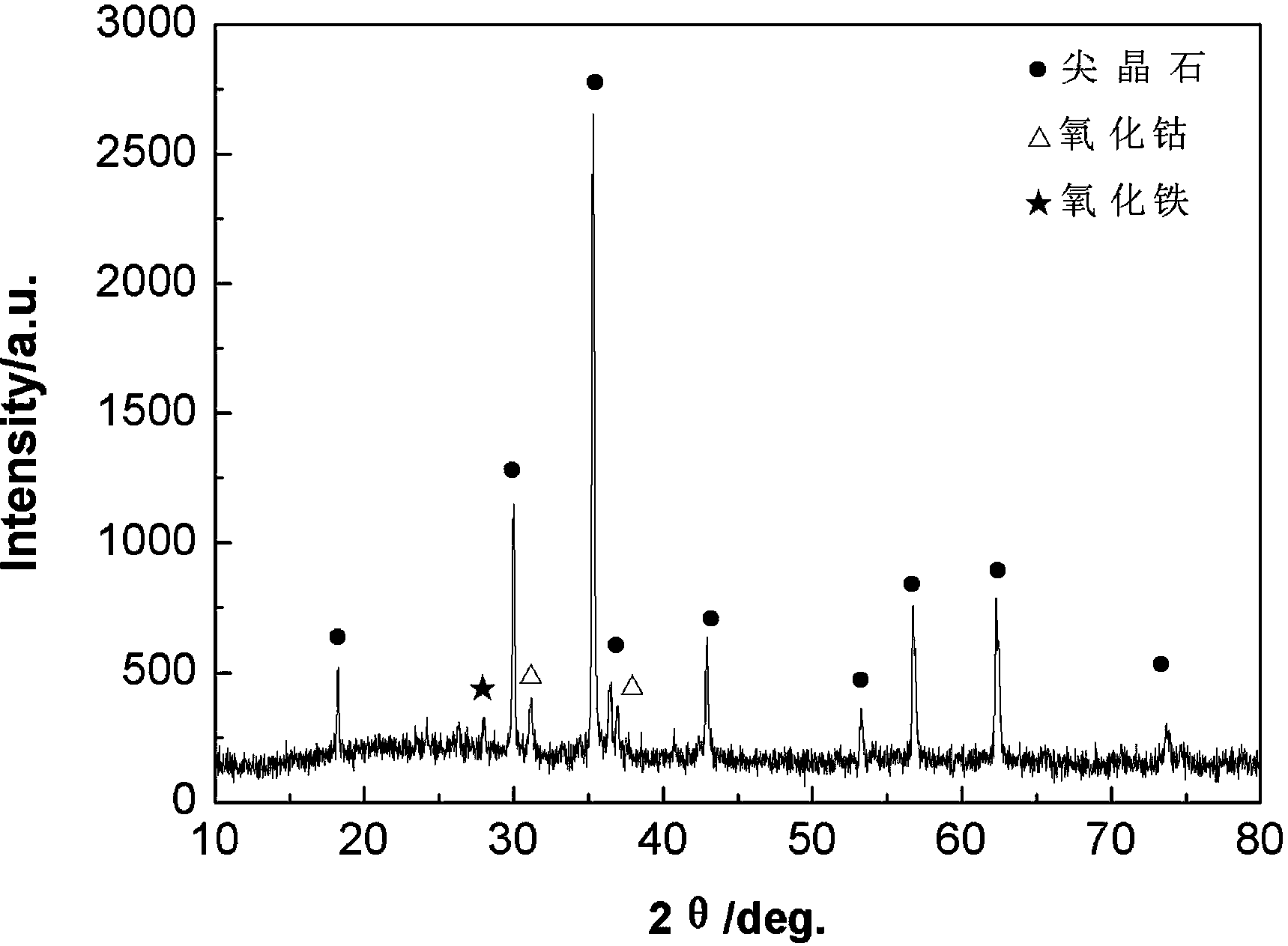

[0034] In step 2, the above-mentioned bulk mixture is sintered at high temperature, that is, at 1350° C., sintered for 3 hours, and subjected to doping and solid solution reaction to form a blackening agent with a spinel structure.

[0035] In step 3, the sintered bulk mixture is cooled, crush...

Embodiment 2

[0037] The blackening agent for high temperature infrared radiation energy-saving coatings is prepared from the following raw materials in percentage by weight:

[0038] MnO 2 : 42%, Fe 2 O 3 : 15%, CuO: 8%, Co 2 O 3 : 5%, NiO: 10%,

[0039] Total of brown corundum and white corundum: 20%.

[0040] The preparation method of above-mentioned blackening agent, its steps are:

[0041] Step 1, the MnO 2 , Fe 2 O 3 , CuO, Co 2 O3 、Cr 2 o 3 , NiO and corundum powder are mixed evenly with a mixer in proportion, and then the mixture is pressed into a block.

[0042] Step 2: Sinter the block mixture at high temperature, that is, sinter at 1350° C. for 2 hours, perform doping and solid solution reaction to form a blackening agent with a spinel structure.

[0043] Step 3, cooling the sintered block mixture, crushing and grinding it to a size below 280 mesh, and obtaining a blackening agent for high-temperature infrared radiation energy-saving coatings. The blackening agent m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com