Antistatic paint, antistatic thin film and preparation method of the antistatic thin film

An antistatic and antistatic agent technology, applied in the direction of coating, etc., can solve problems such as insufficient surface hardness, complicated manufacturing process, and decreased transparency, and achieve the effects of increasing film hardness, good optical effect, and low surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

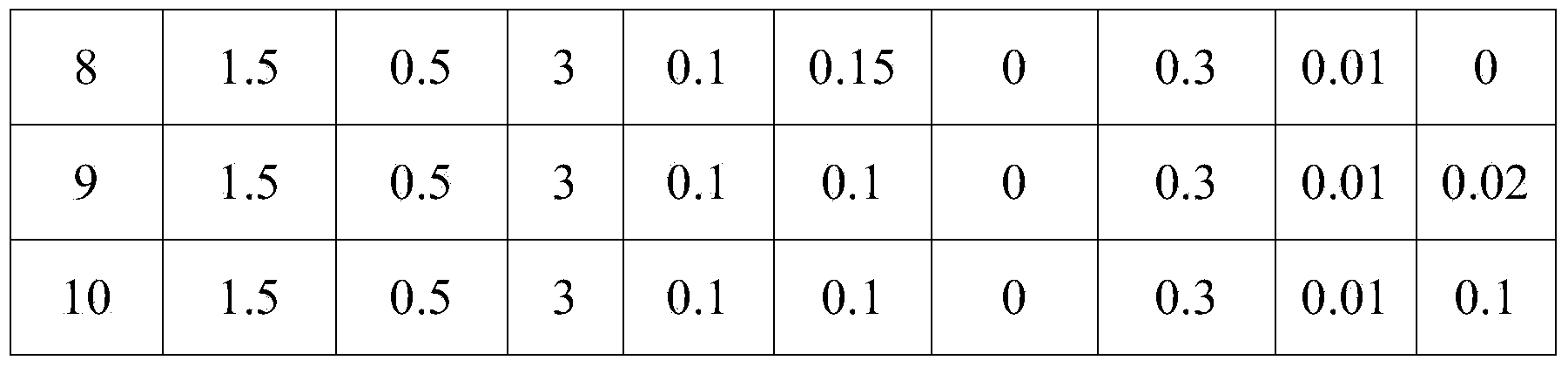

Examples

Embodiment Construction

[0024] In order to make the description of the content of the present invention more detailed and complete, the following provides an illustrative description for the embodiments and specific embodiments of the present invention; but this is not the only form for implementing or using the specific embodiments of the present invention. The various embodiments disclosed below can be combined or replaced with each other when beneficial, and other embodiments can also be added to one embodiment, without further description or illustration.

[0025] In one embodiment of the present invention, the present invention provides an antistatic coating, and this antistatic coating has high hardness and low surface resistance and can form a coating with high weather resistance, high hardness, high penetration rate and low surface resistance Antistatic film.

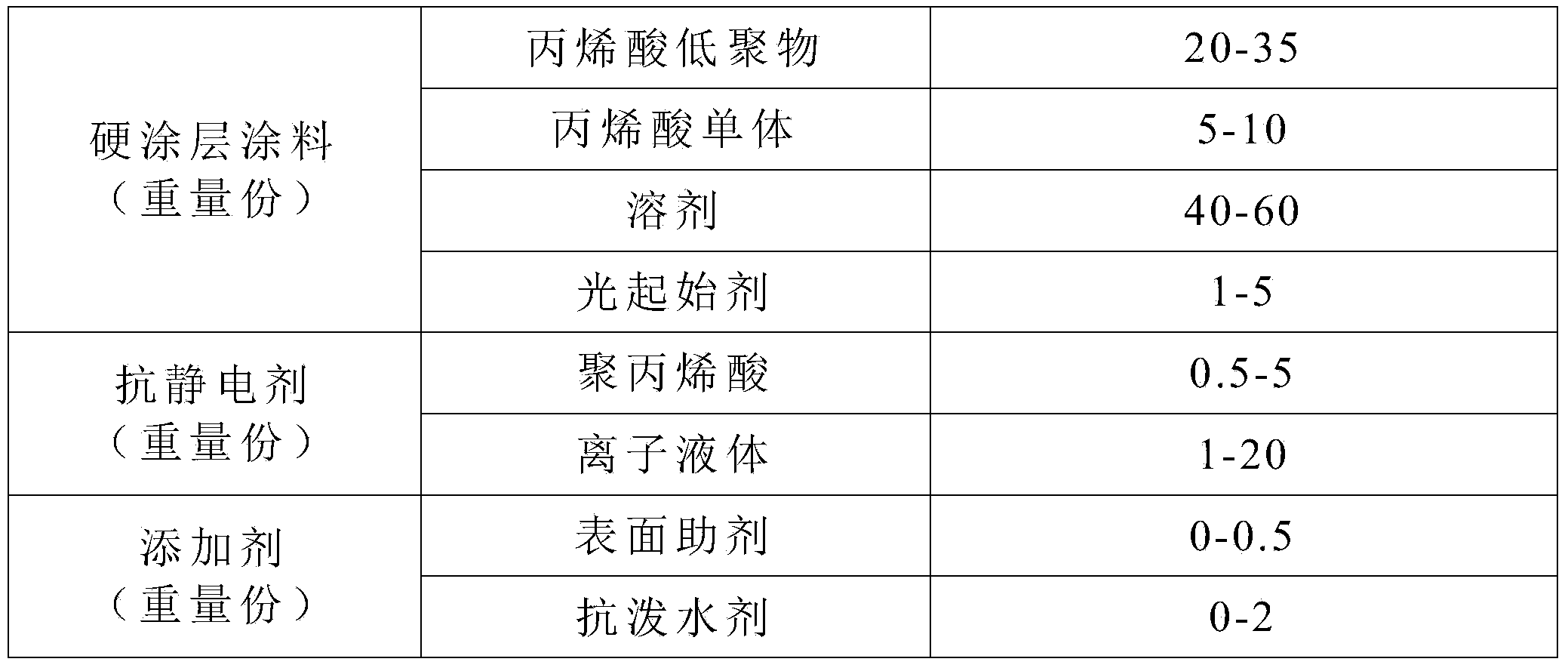

[0026] The antistatic coating provided by the present invention may include a hard coat coating and an antistatic agent, but is not l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com