Inorganic nano compound and preparation method and application thereof

An inorganic nano-composite technology, applied in the installation of electrical components, cable accessories, cables, etc., can solve the problems of poor operating conditions of cable accessories, high cable co-channel ratio, partial discharge, etc., to reduce the intensity of partial discharge, The effect of high conductivity and uniform electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

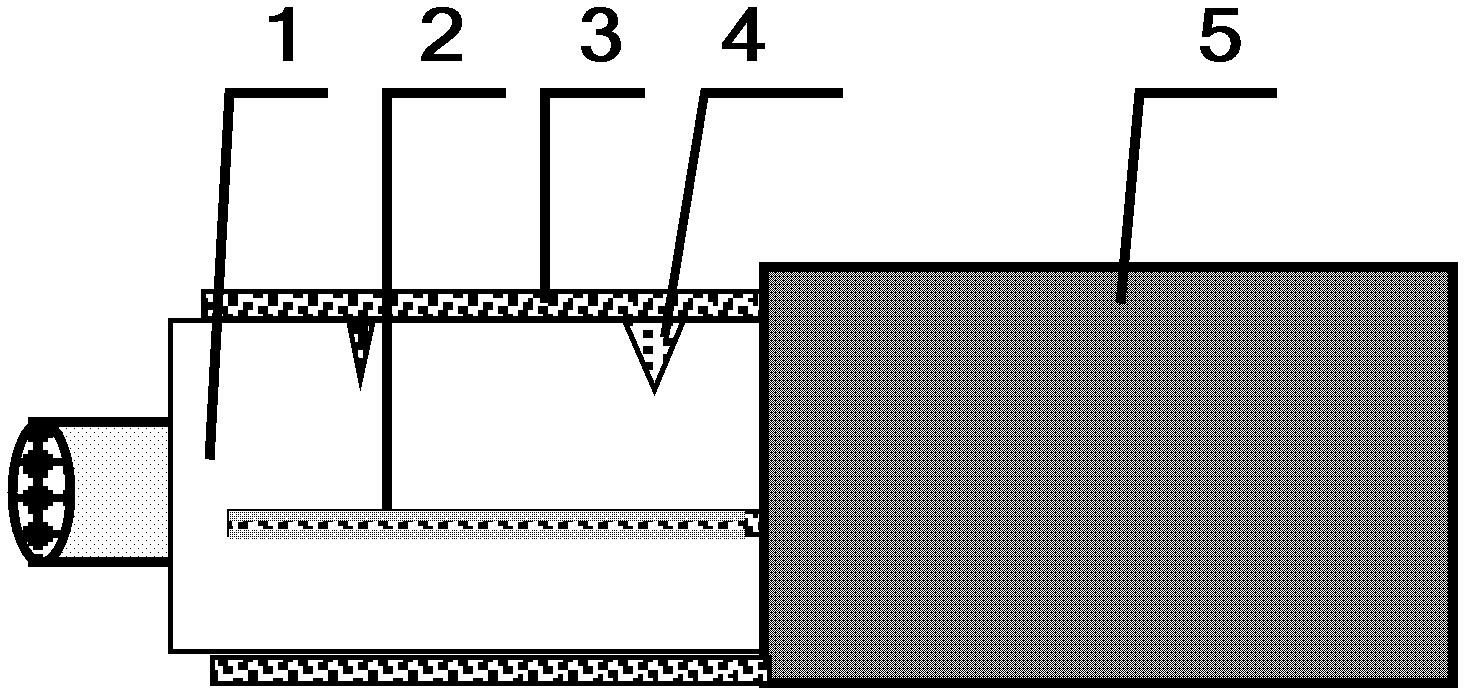

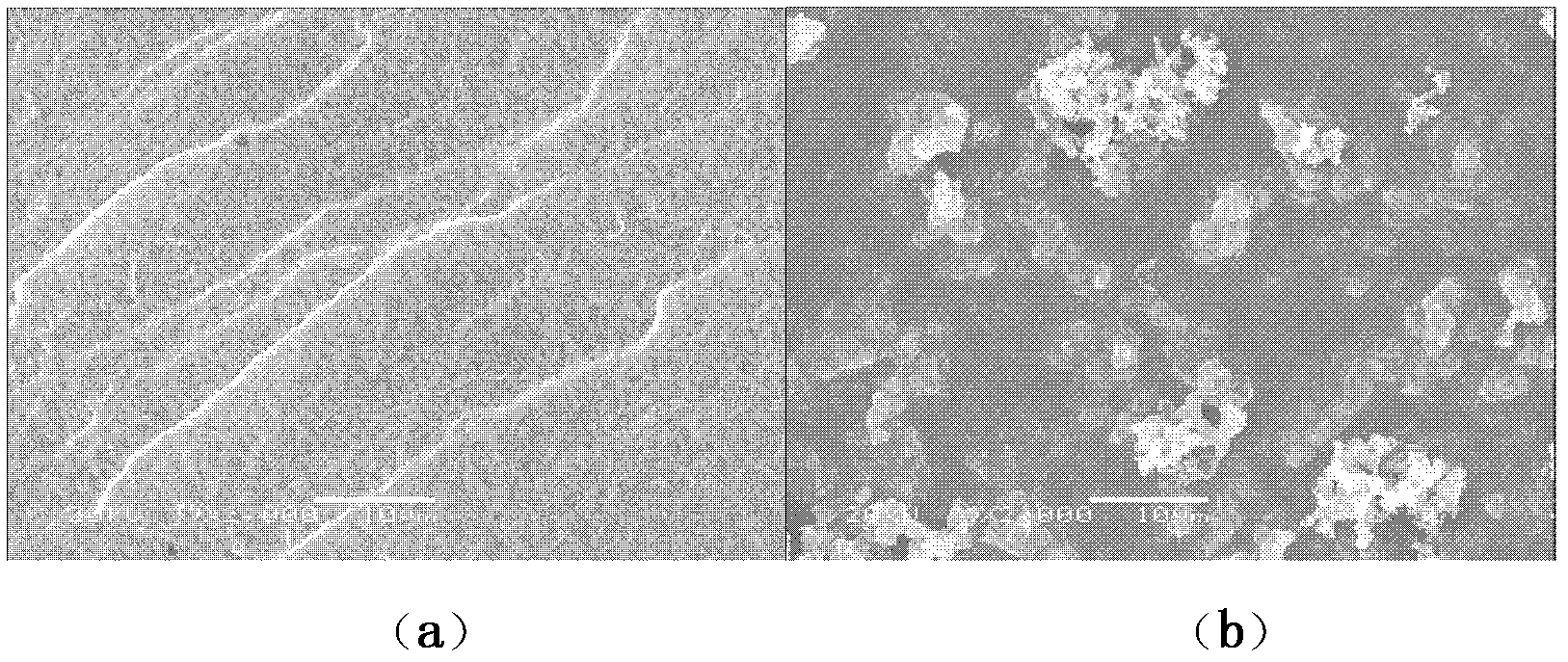

Method used

Image

Examples

Embodiment 1

[0044] (1) Add 10 parts of nano-silica-coated nano-titanium dioxide, 0.5 part of nano-alumina, 0.5 part of nano-silicon dioxide, and 0.5 part of nano-zinc oxide into the mixing container, and disperse and mix evenly by grinding and ultrasonic dispersing machine , the ultrasonic power is 200W, and the frequency is 20kHz.

[0045] (2) Add the mixture prepared above with 20 parts of acetone, 20 parts of diethylene glycol and 1 part of polyethylene glycol into a container with a stirrer, a thermometer and a reflux condenser, and further disperse and mix evenly by grinding and ultrasonic dispersing machine , to obtain a nanoparticle dispersion, wherein the stirring speed is 1500 rpm, the ultrasonic power is 200W, the frequency is 20kHz, and the time is 30min.

[0046] (3) Filter the above-mentioned nanoparticle dispersion with a 800-mesh filter, then add 0.5 parts of ethylene glycol monobutyl ether and 0.5 part of ethanolamine to the above-mentioned filtrate and stir evenly, with a...

Embodiment 2

[0054] (1) Add 15 parts of nano-titanium dioxide coated with nano-silica, 2 parts of nano-alumina, 2 parts of nano-silicon dioxide, and 2 parts of nano-zinc oxide into the mixing container, and disperse and mix evenly by grinding and ultrasonic dispersing machine , the ultrasonic power is 500W, and the frequency is 24kHz.

[0055] (2) Add the mixture prepared above with 80 parts of carbon tetrachloride and 2 parts of oxidized polyethylene glycol into a container with a stirrer, a thermometer and a reflux condenser, and further disperse and mix evenly by grinding and ultrasonic dispersing machine, A nanoparticle dispersion was obtained, wherein the stirring speed was 2000 rpm, the ultrasonic power was 500 W, the frequency was 24 kHz, and the time was 60 min.

[0056] (3) The above-mentioned nanoparticle dispersion is filtered with a 1000-mesh filter screen, then 1 part of propylene glycol ether and 1 part of ammonia are added to the above-mentioned filtrate and stirred evenly, ...

Embodiment 3

[0064] (1) Add 12 parts of nano-titanium dioxide coated with nano-silica, 1 part of nano-alumina, 1 part of nano-silicon dioxide, and 1 part of nano-zinc oxide into the mixing container, and disperse and mix evenly by grinding and ultrasonic dispersing machine , the ultrasonic power is 300W, and the frequency is 22kHz.

[0065] (2) Add the mixture prepared above with 40 parts of salicyl alcohol, 20 parts of xylitol and 1 part of polyacrylamide into a container with a stirrer, thermometer and reflux condenser, and further disperse and mix by grinding and ultrasonic dispersing machine Uniformly, to obtain a nanoparticle dispersion, wherein the stirring speed is 1500 rpm, the ultrasonic power is 300W, the frequency is 22kHz, and the time is 50min.

[0066] (3) The above-mentioned nanoparticle dispersion is filtered with a 900-mesh filter screen, then 1 part of ethylene glycol and 1 part of potassium hydroxide are added to the above-mentioned filtrate and stirred evenly, the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com