Catalyst for removing carbon monoxide, hydrocarbons and particulate matters in engine

A particulate matter and carbon monoxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of preventing air pollution, ceramic filter performance degradation, Oxidation and other problems, to achieve excellent oxidation ability, excellent oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

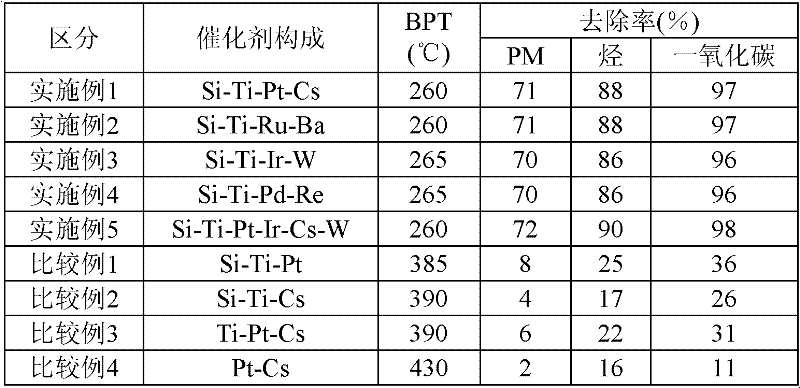

Examples

Embodiment 1

[0016] In order to prepare the Si-Ti-A-B composite catalyst, 50 g of ethylhexyloxyisopropoxide silicon as Si metal, 50 g of TiCl as Ti metal 4 , 5g of chloroplatinic acid as platinum group metal A, 5g of cesium nitrate as metal B of the 6th period, and 500g of 10% aqueous hydrochloric acid were mixed, and stirred for 3 hours at a temperature of 90°C at a speed of 60rpm to prepare Si- Ti-Pt-Cs composite catalyst; then, in the prepared Si-Ti-Pt-Cs composite catalyst, mix 10g of ethanol as alcohol and 10g of hexamethyldisilane as silane to prepare Si-Ti-Pt-Cs Composite catalyst coating solution; respectively make 2 porosity (porosity) be 30PPI and 3 porosity 50PPI, diameter is 7 inches, the foam body of Fe-Cr-Al material that thickness is 1 inch is impregnated in above-mentioned Si -Ti-Pt-Cs composite catalyst coating solution, dried at 110°C for 6 hours, then fired at 400°C for 2 hours to obtain Si-Ti-Pt-Cs composite for reducing soot at low temperature For the catalyst foam, t...

Embodiment 2

[0018]To prepare the Si-Ti-A-B composite catalyst, 50 g of silicon ethoxylate as Si metal, 50 g of tetraisopropoxytitanium as Ti metal, 5 g of ruthenium chloride as platinum group metal A, 5 g of ruthenium chloride as the 6th cycle The barium nitrate of metal B and the 10% sulfuric acid aqueous solution of 500g are mixed, stir 3 hours with the speed of 60rpm at the temperature of 90 ℃, thereby prepare Si-Ti-Ru-Ba composite catalyst; Then, to prepared Si-Ti -In the Ru-Ba composite catalyst, mix 10g of isopropanol as alcohol and 10g of phenylmethylsilane as silane to prepare Si-Ti-Ru-Ba composite catalyst coating solution; make 2 porosities of 30PPI and 3 respectively A stainless steel foam body with a porosity of 50PPI, a diameter of 7 inches, and a thickness of 1 inch is impregnated with the above-mentioned Si-Ti-Ru-Ba composite catalyst coating solution, dried at a temperature of 110° C. for 6 hours, and then dried at 400° C. ℃ for 2 hours to obtain the Si-Ti-Ru-Ba composite ...

Embodiment 3

[0020] To prepare the Si-Ti-A-B composite catalyst, 50 g of silicon ethoxylate as Si metal, 50 g of tetraisopropoxytitanium as Ti metal, 5 g of iridium chloride as platinum group metal A, 5 g as cycle 6 Ammonium tungstate of metal B and 500g of 10% nitric acid aqueous solution were mixed, stirred at a speed of 60rpm at a temperature of 90°C for 3 hours to prepare a Si-Ti-Ir-W composite catalyst; then, to the prepared Si- Mix 10g propanol as alcohol and 10g methyltrimethoxysilane as silane in the Ti-Ir-W composite catalyst to prepare Si-Ti-Ir-W composite catalyst coating solution; make 2 porosities of 30PPI and Three stainless steel foams with a porosity of 50PPI, a diameter of 7 inches, and a thickness of 1 inch were impregnated in the above-mentioned Si-Ti-Ir-W composite catalyst coating solution, dried at a temperature of 110°C for 6 hours, and then placed in a Fire at a temperature of 400°C for 2 hours to obtain a Si-Ti-Ir-W composite catalyst foam for reducing soot at low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com