Soybean oil powder grease and preparation method thereof

A technology for powdered oil and soybean oil, applied in the field of soybean oil powdered oil and its preparation, can solve the problems of less research, research staying in the laboratory, industrialization of soybean powdered oil products and blank market application, etc., to improve instant solubility , Reduce the generation of fine powder and improve the effect of embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

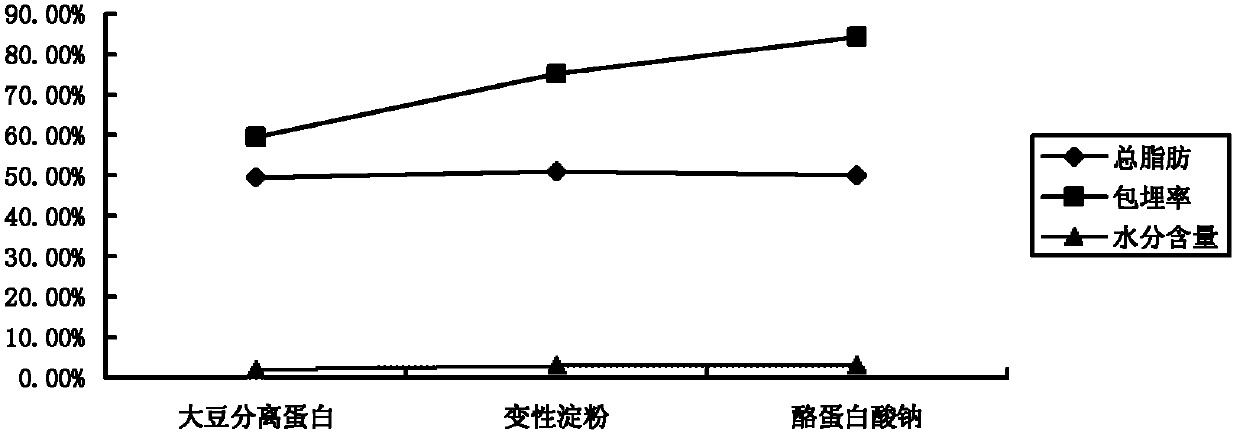

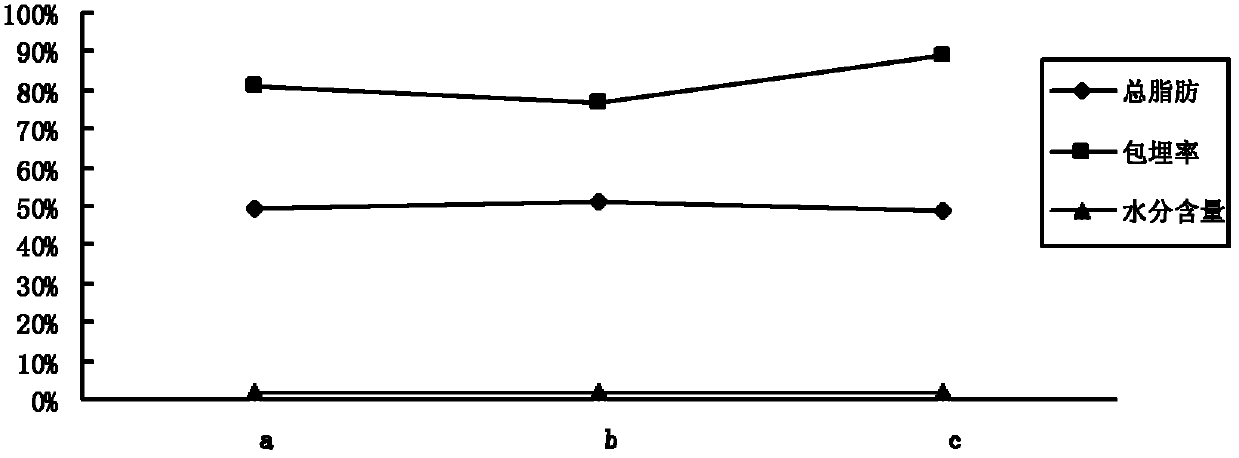

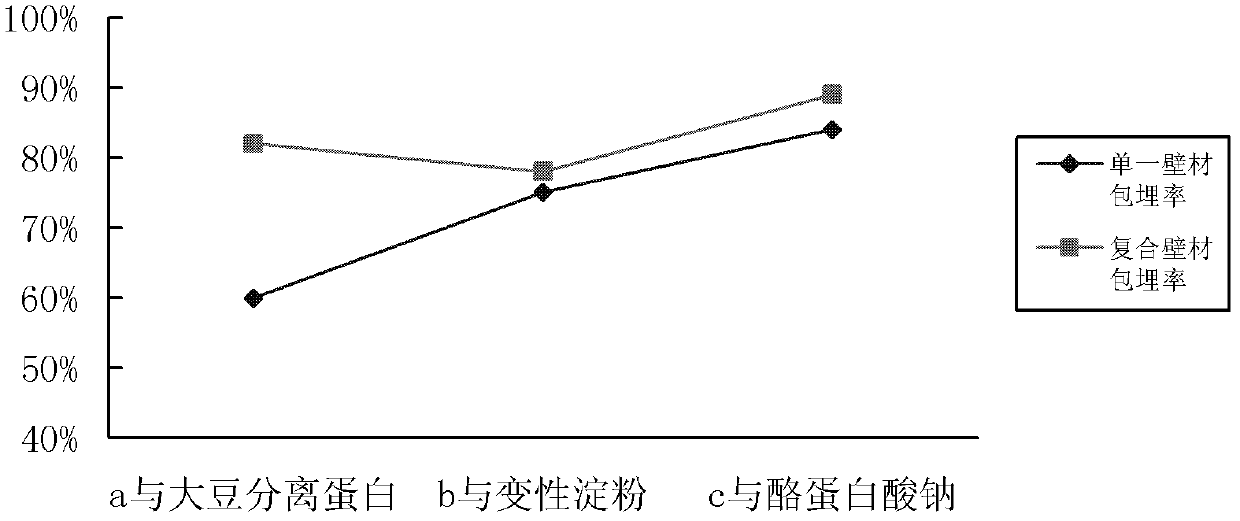

[0150] Example 1 Influence of wall material on powder oil embedding effect

[0151] Using microcapsule technology and spray drying method to produce soybean powder oil products, the main work is to screen out microcapsule wall materials with good effect. The main components that make up the wall material are also called embedding agents, membrane materials, wrapping materials, etc., and are a class of macromolecular organic materials. The wall material should have suitable physical properties, suitable for economical and reasonable microcapsule manufacturing methods, and be compatible with the core material without chemical reaction, non-toxic, and should also have appropriate permeability, hygroscopicity, solubility and stability. sex. The embedding agents used in the production of microencapsulated powder oils mainly include gums, polysaccharides, starches, cellulose, and proteins. In this test, through the analysis of the properties of various film-forming substances, the...

Embodiment 2

[0171] Example 2 Study on Emulsification Stability

[0172] Due to the different chemical structures of various oils, their affinity with emulsifiers is also different. Therefore, when various oils are emulsified, the HLB values that need to be adapted are also different. The choice of emulsifier is also very necessary. However, usually an emulsifier only corresponds to one HLB value, which cannot meet the needs of the HLB value of any oil product. Therefore, the present invention solves this problem by adopting the compounding of monoglyceride and sucrose ester.

[0173] (1) Influence of HLB value on emulsion stability

[0174] The total amount of material is configured by 100g, taking 50% of soybean first-grade oil, adding compound embedding agent - sodium caseinate and modified starch (1:1) 5%, maltodextrin 43%, compound emulsifier 2%, compound The mass ratio of sucrose ester and monoglyceride selected as the emulsifier is 10:0, 9:1, 8:2, 7:3, 6:4, respectively, put i...

Embodiment 3

[0193] Example 3 Determination of the optimal formula of soybean powder oil

[0194] The total mass of the material is configured with 200g, 50% soybean oil is used as the core material, and the rest of the materials are weighed according to the mass percentage in the following table, respectively, put into a beaker, add 300g of water, and after stirring, it is sheared at high speed by a colloid mill three times and mixed. The emulsion obtained after homogenization is used for later use; after the batching is completed, the emulsion is placed in a water bath at 60° C. for 20 minutes, and the stirring speed is 50 r / min; In this experiment, the ratio and content of composite embedding agent sodium caseinate and modified starch, and the ratio and content of emulsifier sucrose ester and monoglyceride were taken as three levels respectively, and an orthogonal experiment was designed.

[0195] The orthogonal test results are shown in Table 8.

[0196] Table 8 Orthogonal test result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com