Negative-pressure structure easy for oil return of oil injector

A fuel injector and negative pressure technology, which is applied in the direction of machine/engine, fuel injection device, engine components, etc., can solve the problems of high oil return pressure, instability, and the influence of normal operation of the injector, so as to improve the oil return efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

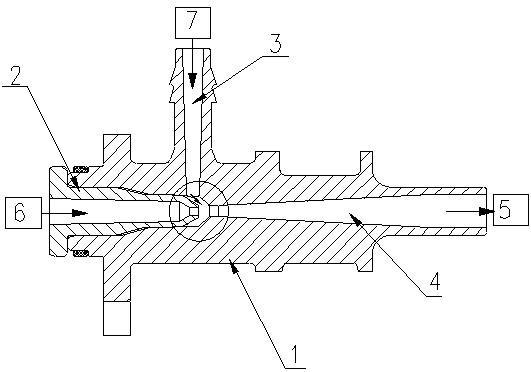

[0014] In the existing oil supply system, in addition to the oil return structure for the injector, the oil return structure is also set for the oil pump. The oil return pressure of the oil pump mainly comes from the pushing action of the oil pump, so the oil return pressure of the oil pump The oil pressure is relatively large, and the oil pressure is relatively stable, and the oil returned by the oil pump and the injector finally returns to the oil tank. Therefore, the inventor considers using the pressure of the oil returned by the oil pump to generate the Venturi effect, and then uses the Venturi effect to extract the oil from the injector. Oil return, so as to ensure smooth oil return of the injector, the specific plan is:

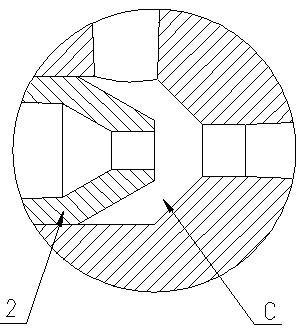

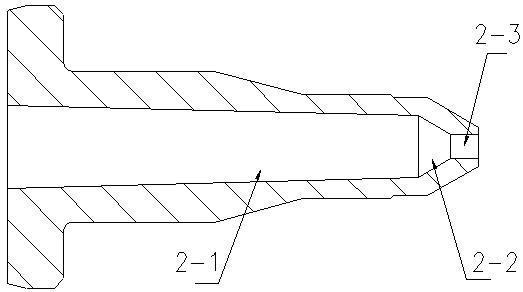

[0015] A negative pressure structure that is convenient for injector oil return, which is composed of a negative pressure structure 1 and a nozzle 2; the negative pressure structure 1 is provided with a nozzle installation groove, an injector return oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com