Industrial solid waste fiber paper slurry as well as making method and application thereof

A solid waste and industrial technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, special paper, fiber raw materials, etc., can solve problems such as ecological environment damage, achieve environmental protection, increase application added value, The effect of protecting forest resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

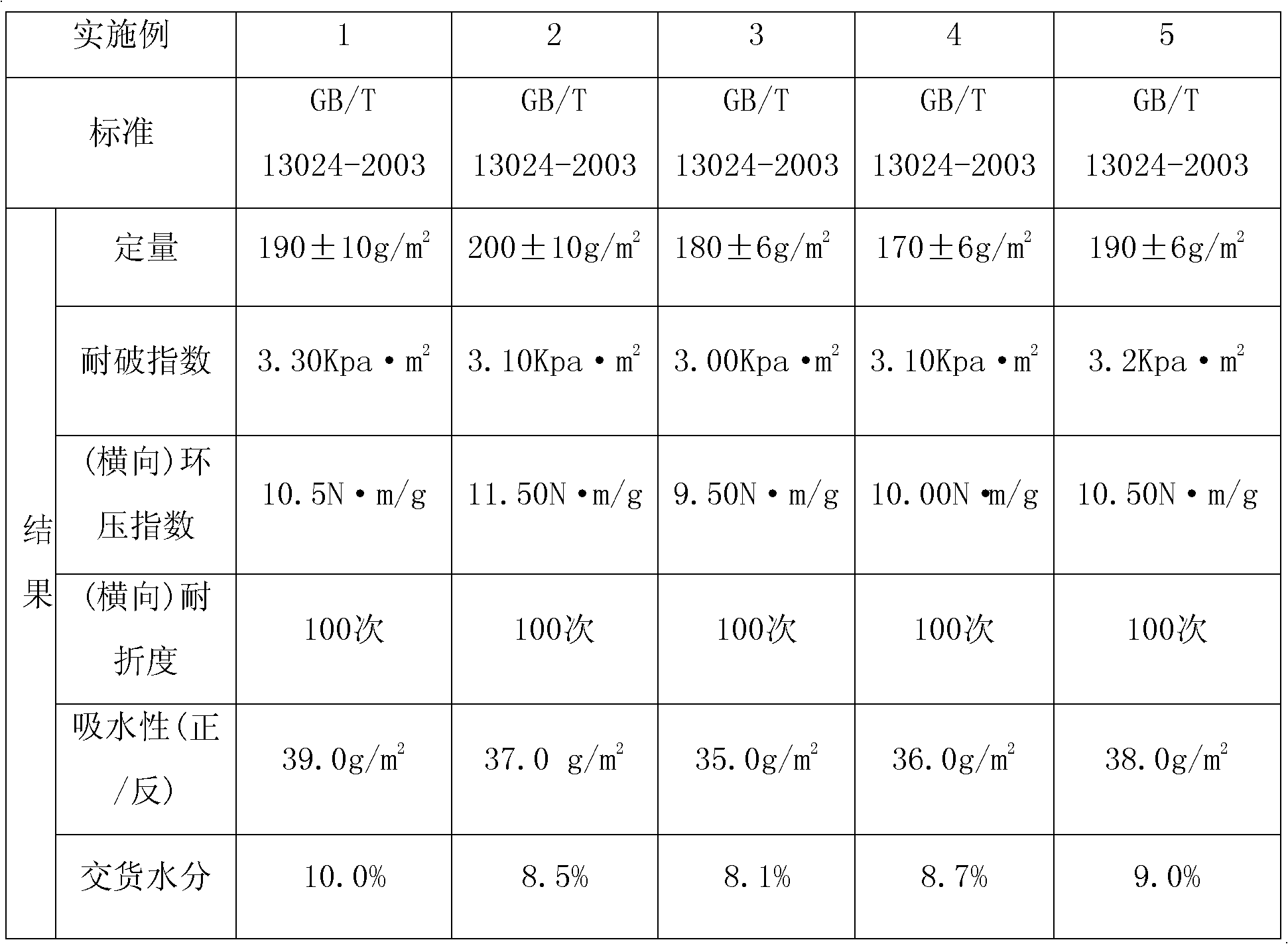

[0021] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples. During specific implementation, the steps are as follows:

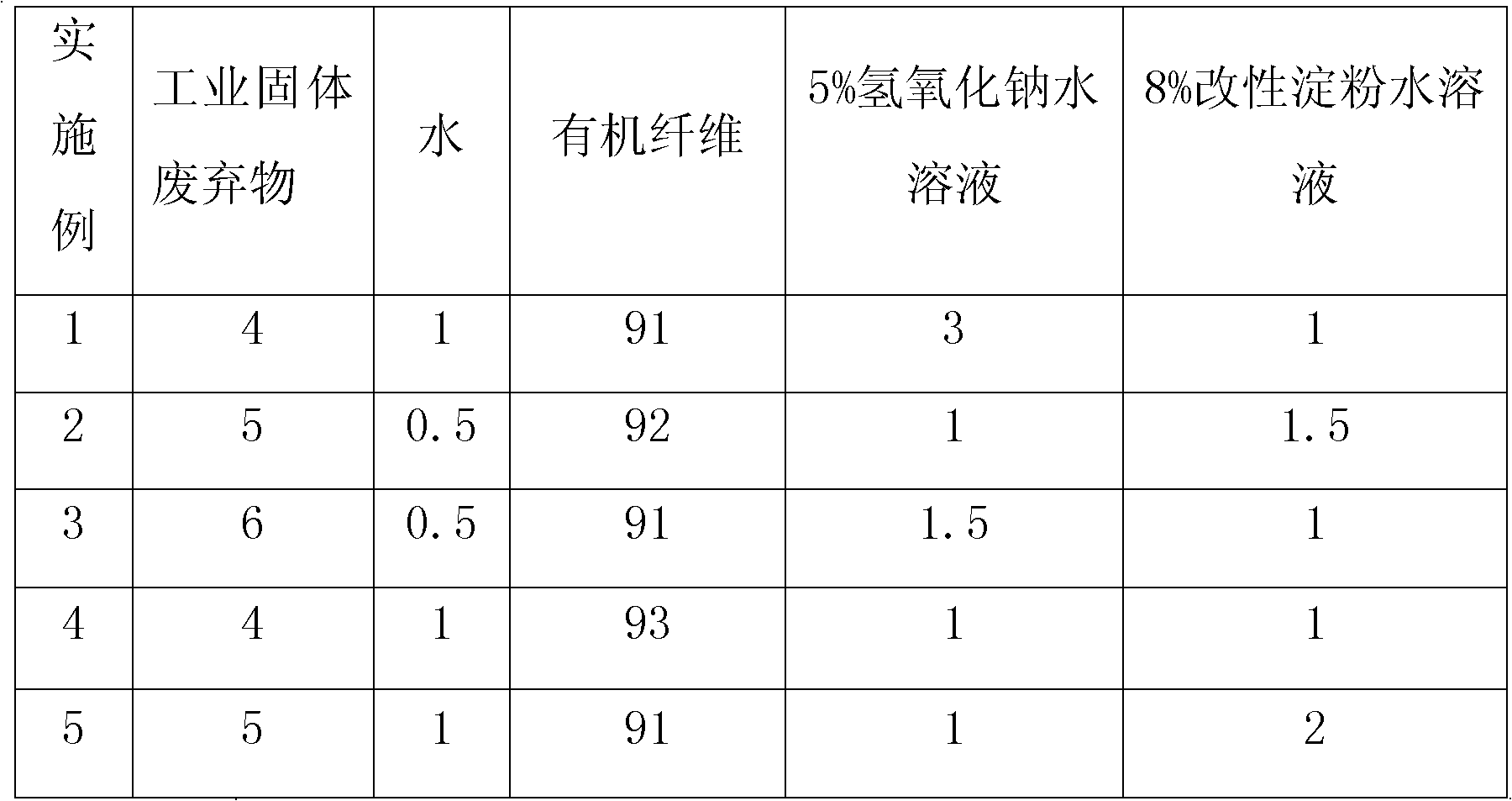

[0022] At first, raw material is equipped with by the ratio in the table, industrial solid waste, organic fiber, 5% sodium hydroxide aqueous solution, 8% modified starch aqueous solution, the specific selection and dosage of water are shown in Table 1 (components are made by weight percentage) ).

[0023] Next, mix the industrial solid waste with the combustion aid coke and the catalyst high-calcium dolomite and put them into the melting furnace. Under the combustion aid of the combustion aid, they are burned to 1600°C and formed into a slurry.

[0024] The pulped raw materials are introduced into the fiber forming machine to generate preliminary inorganic fibers, and the preliminary inorganic fibers are introduced into the fiber forming room for screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com