Process and equipment for extracting hydrogen from air discharged from synthetic ammonia tank

A technology for releasing air and synthesizing ammonia, which is applied in the field of air releasing and hydrogen extraction technology and equipment in a synthetic ammonia storage tank, can solve the problems of high consumption of raw coal, low added value of products, low utilization rate of raw gas, etc., and achieves energy saving and good economic benefits. and social benefits, the effect of increasing the added value of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Ammonia storage tank release air data:

[0028] Output is 1200Nm 3 / h; Composition: H 2 19.5%, N 2 5%, CH 4 14%, Ar1.5%, NH 3 60%; the pressure is 2.2±0.5MPa.

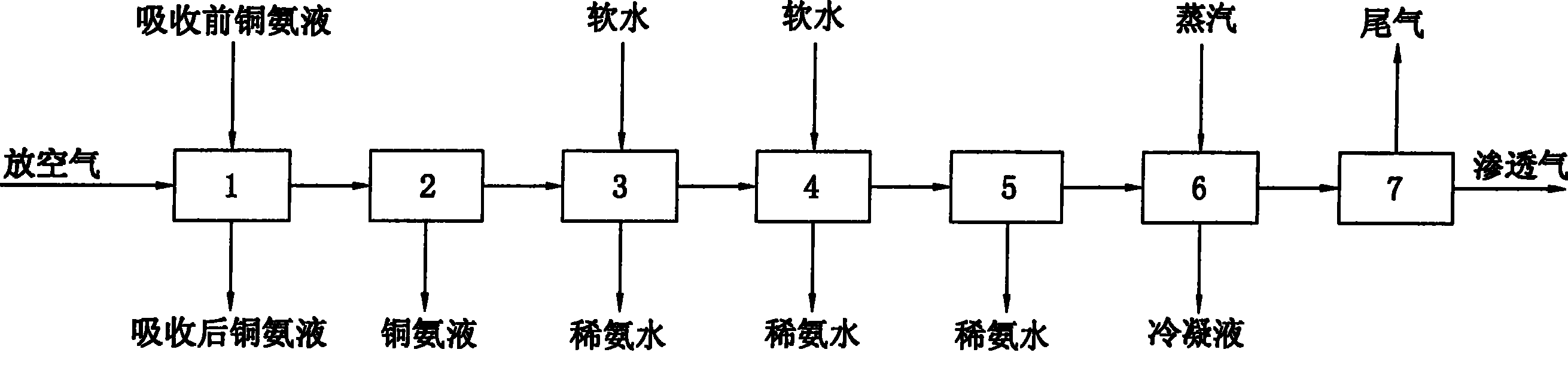

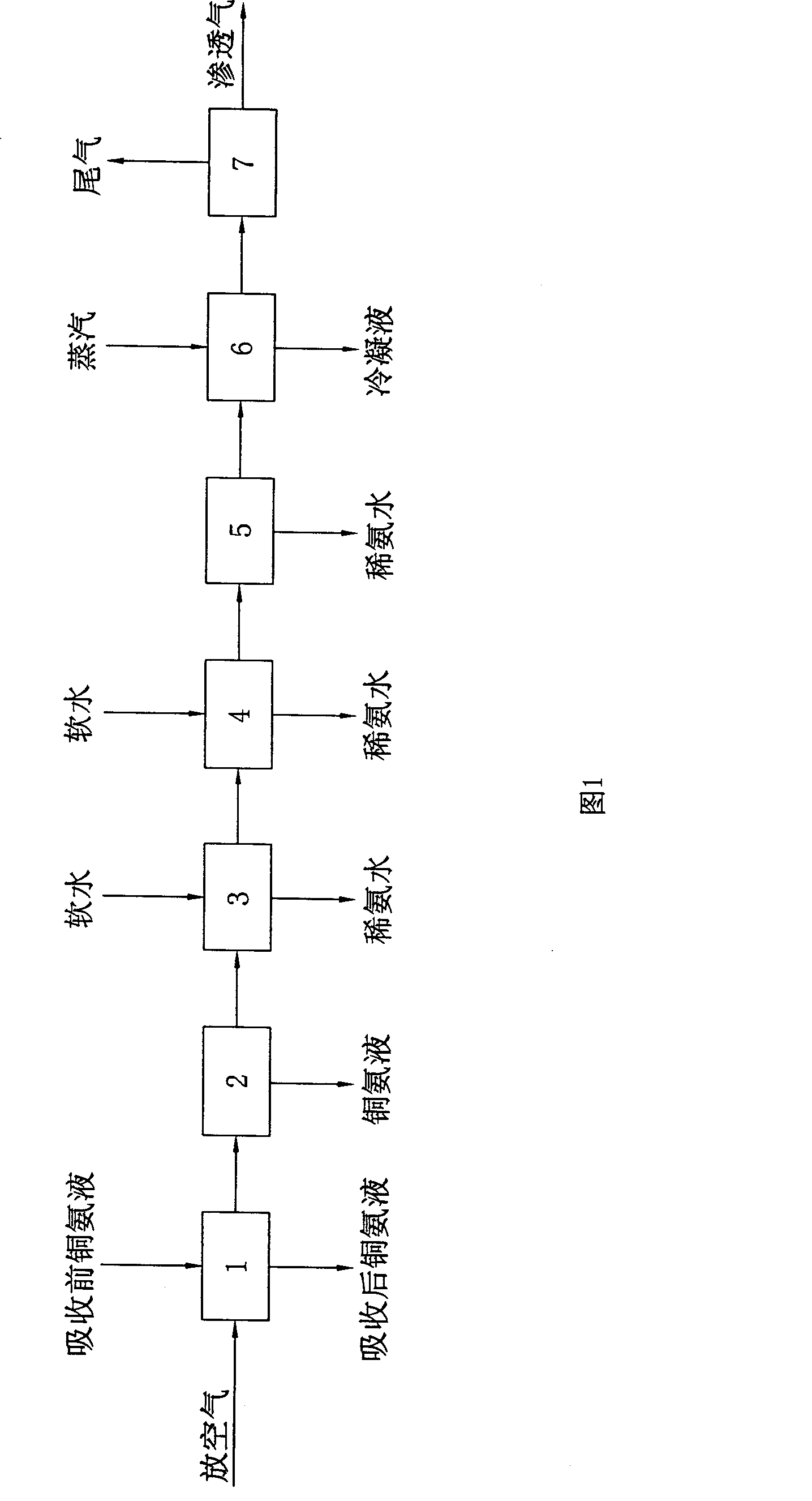

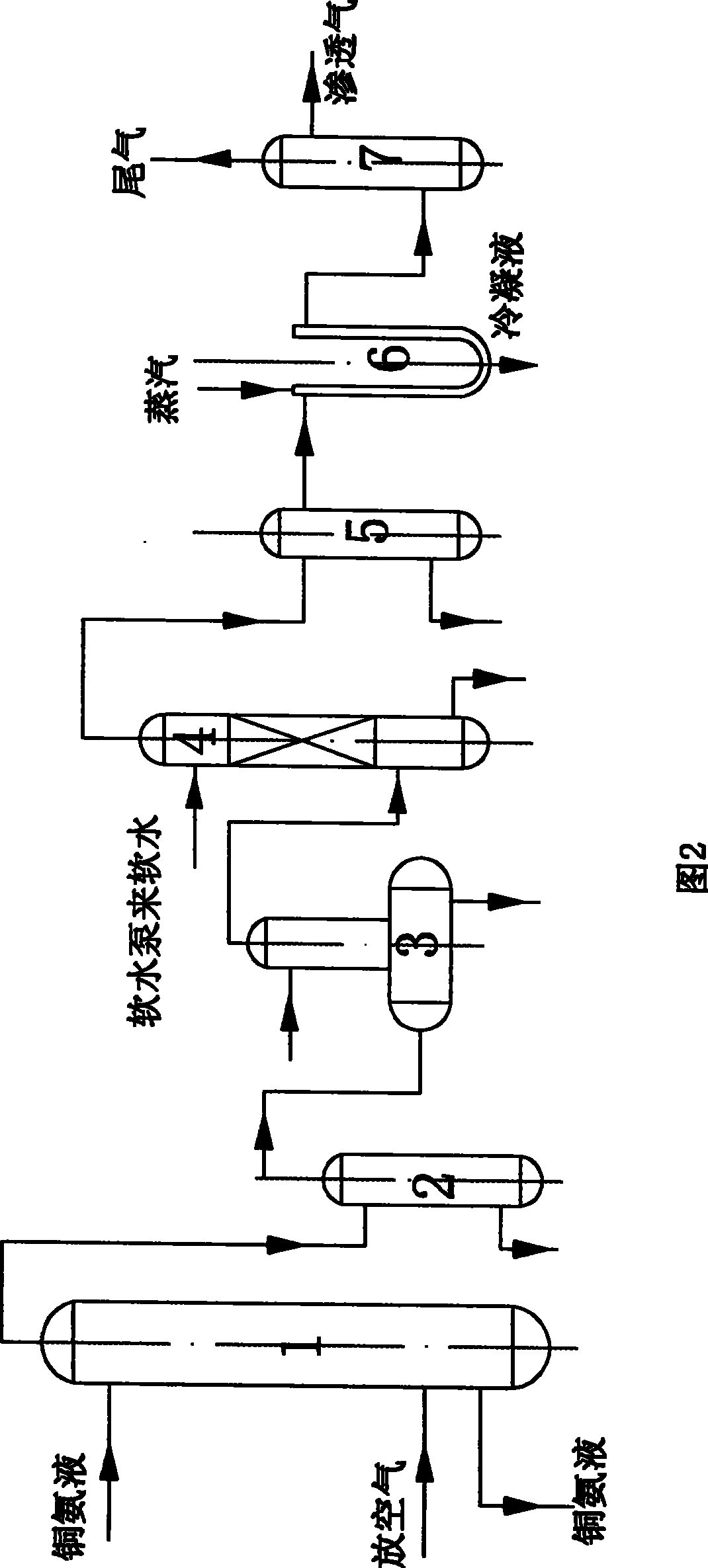

[0029] Selected equipment: copper cleaning ammonia tower 1, copper liquid separator 2, equal pressure ammonia cleaning device 3, ammonia washing tower 4, gas-liquid separator 5, casing heater 6, membrane separator 7.

[0030] Hydrogen extraction process:

[0031] a. Net ammonia:

[0032] 1) will come from the synthetic ammonia storage tank containing H 2 , N 2 , NH 3 、CH 4 After being filtered by the pipeline filter, the exhausted air is sent to the copper cleaning ammonia tower 1 from the bottom, and is reversely contacted with the low-ammonia copper ammonia liquid sent from the top of the tower to perform primary ammonia purification. (The ammonia-rich copper ammonia liquid obtained after absorbing ammonia flows out from the bottom of the tower and is sent to the refining ammonia cooler to be used a...

Embodiment 2

[0043] Ammonia storage tank release air data:

[0044] Output is 1800Nm 3 / h; Composition: H 2 21%, N 2 4.5%, CH 4 15%, Ar1.5%, NH 3 58%; the pressure is 2.3±0.5MPa.

[0045] Selected equipment: copper cleaning ammonia tower, copper liquid separator, equal pressure ammonia cleaning device, ammonia washing tower, gas-liquid separator, casing heater, membrane separator.

[0046] Hydrogen extraction process: It is basically the same as the hydrogen extraction process in Example 1, but the ammonia content of the gas after three-stage ammonia purification is required to be 130±50PPm. The pressure on the permeate side is 0.4±0.2MPa, and the pressure on the tail gas side is 1.7±0.2MPa.

[0047] After hydrogen extraction, the hydrogen concentration in the permeate gas is 82%, and the hydrogen concentration in the tail gas can be reduced to below 4% (no explosion when energized).

[0048] The hydrogen recovery rate is 80%.

[0049] The output value of the hydrogen conversion sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com