Rubber oil with low aromatic hydrocarbon content and preparation method thereof

A technology of low aromatic hydrocarbon and rubber oil, applied in the field of low aromatic hydrocarbon content rubber oil and its preparation, can solve the problems such as the inability to meet the requirements of SBS rubber filler oil, the unreasonable utilization of naphthenic distillate oil, and the lack of naphthenic hydrocarbon content, etc. Achieve the effect of high target product yield, low aromatics content and moderate hydrogenation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1, SBS rubber oil

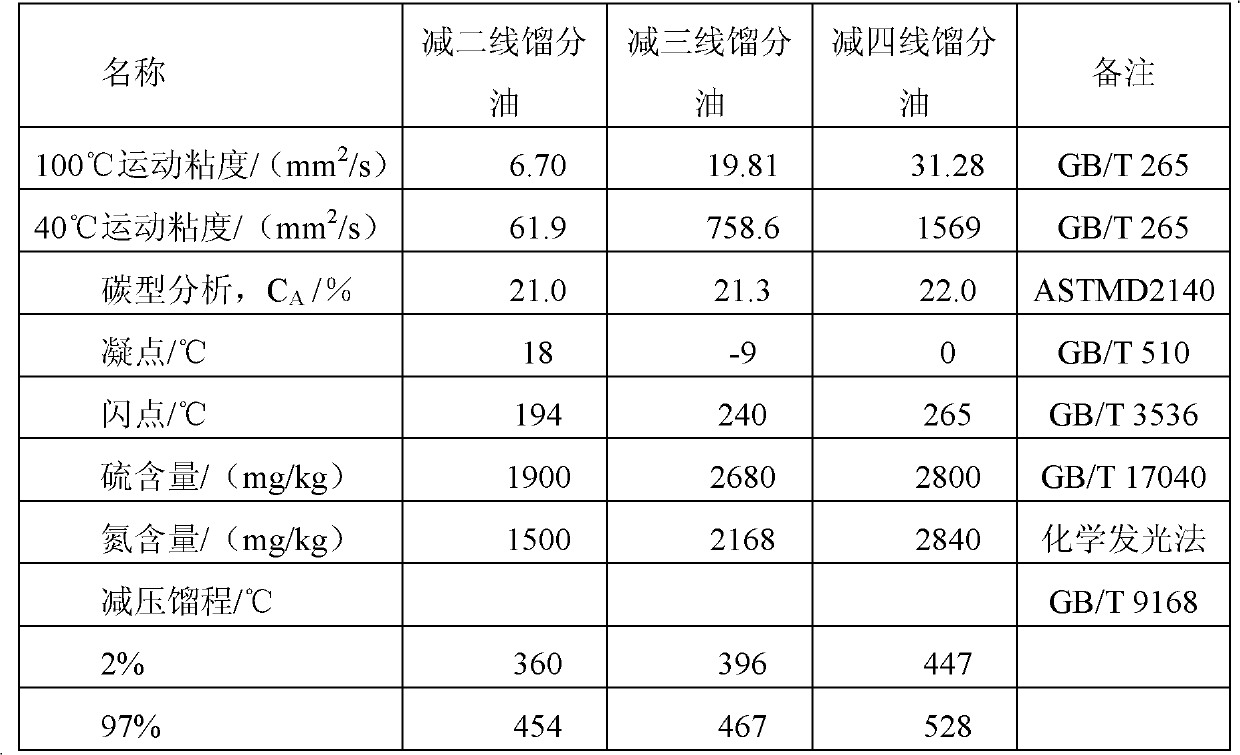

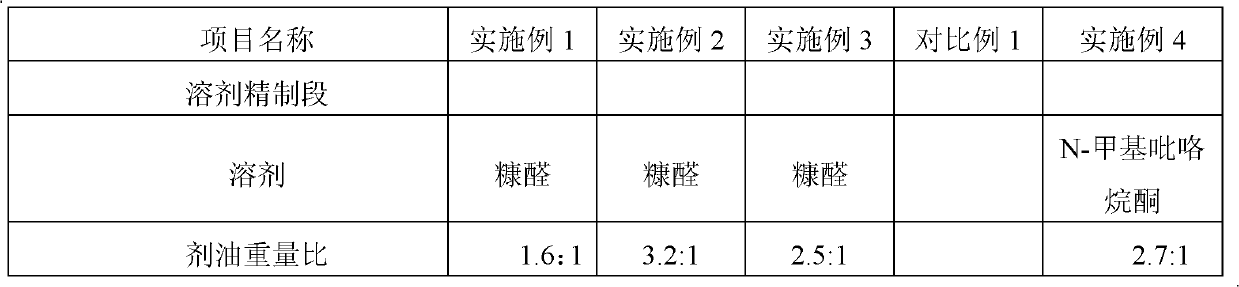

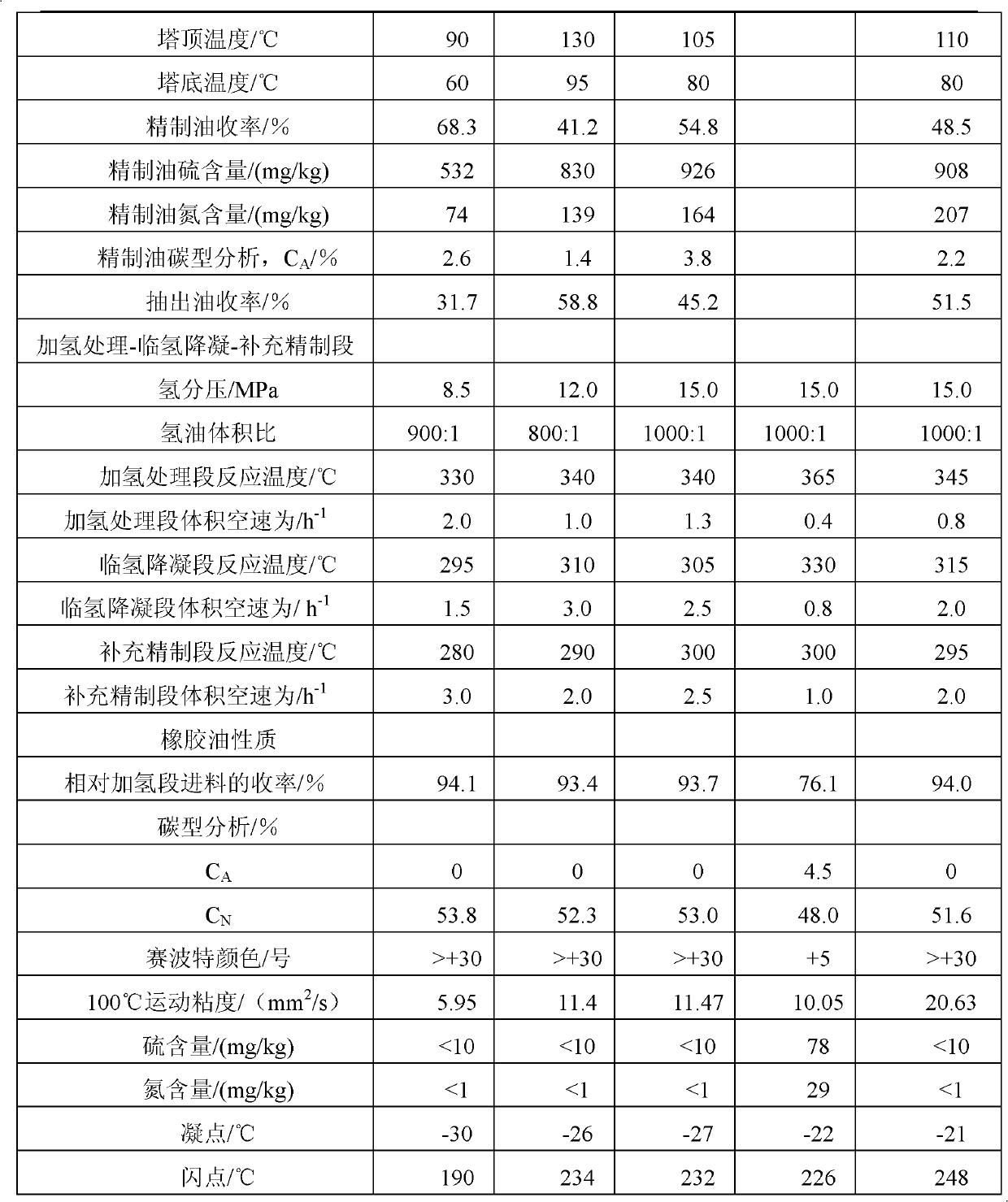

[0031] (1) With the Caofeidian crude oil minus the second-line distillate oil produced by the industrial plant of CNOOC Zhanjiang Fuel Oil Co., Ltd. as raw material (the properties of the raw material oil are shown in Table 1), the test is carried out in the solvent refining device (the total feed amount of raw material oil and solvent is 3kg / h, random packing is placed in the tower, the number of theoretical plates is 3 theoretical plates), the solvent is furfural, the agent-oil weight ratio is 1.6: 1, the temperature at the top of the refining tower is 90°C, and the temperature at the bottom of the tower is 60°C. The bottom product of the tower is the extract liquid. After recovering the solvent, the extract oil is obtained, which is used as the raw material for the production of high-aromatic environmentally friendly rubber oil; the product at the top of the refining tower is the refined liquid, and the refined oil is o...

Embodiment 2

[0035] The preparation of embodiment 2, SBS rubber oil

[0036] (1) Using the third-line naphthenic distillate oil produced by the industrial plant of China Shipping Asphalt Co., Ltd. as raw material (see Table 1 for the properties of the raw material oil), the test was carried out in a small test device for solvent refining (the total feed amount of raw material oil and solvent is 3kg / h, random packing is placed in the tower, and the number of theoretical plates is 3 theoretical plates), the solvent is furfural, the agent-oil weight ratio is 3.2: 1, the temperature at the top of the refining tower is 130°C, and the temperature at the bottom of the tower is 95°C. The bottom product of the refining tower is the extract liquid. After recovering the solvent, the extract oil is obtained, which is used as the raw material for the production of high-aromatic environmental protection rubber oil; ASTM D2140 method testing, C A The value is 1.4%, indicating that the content of aromat...

Embodiment 3

[0039] The preparation of embodiment 3, SBS rubber oil

[0040] The feedstock oil used in this embodiment, solvent refining unit, hydrogenation unit, and each hydrogenation catalyst are all the same as in Example 2, but the solvent refining operating conditions, the loading amount and operating conditions of each catalyst in the reactor in the hydrogenation process are the same as those in Example 2. Example 2 is different, see Table 2 for details; the whole fraction of the obtained hydrogenated oil is distilled, and the fraction greater than 360° C. is used as SBS rubber oil.

[0041] The performance parameters of the rubber oil prepared in this embodiment are shown in Table 2. As can be seen from the data in Table 2, reducing the temperature and the ratio of furfural refining to oil can improve the yield of refined oil, while the aromatics content, sulfur content and The nitrogen content is also increased, and high-quality SBS rubber oil can also be obtained by adjusting the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com