Preparation method for thermoset high temperature resistant methyl phenyl silicone resin

A technology of methyl phenyl silicon and high temperature resistance, which is applied in the field of preparation of thermosetting and high temperature resistant methyl phenyl silicone resin, can solve the problems of affecting popularization and application, small production scale and high cost, so as to overcome potential safety hazards and avoid gelling. The effect of less chemical impurities and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

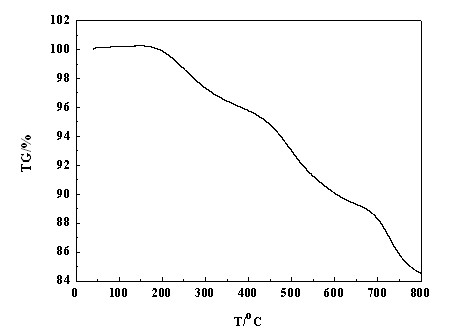

[0040] The fixed Ph / R value is 0.1 and the R / Si value is 1.2. Add 47.84 g of methyltrichlorosilane, 4.128 g of dimethyldichlorosilane, 9.168 g of methylphenyldichlorosilane and 91.704 g of xylene into a 1000 mL four-neck flask, keep stirring fully under an ice-water bath, drop Add a mixture of water and acetone, wherein the mass of water is 161.28 g, and the mass of acetone is 80.64 g. Keep for 3~5 h to complete the dropwise addition, and stir well to continue the reaction for 2 h. After the reaction, the upper oil layer was washed with water until neutral to obtain a white turbid prepolymer. Concentrate the prepolymer under reduced pressure at 120 °C to a solid content of 50-70 %, add 0.2445 g of stannous octoate condensation catalyst (the amount is 0.4 % of the total mass of monomers) at 150 °C, heat-preserve polycondensation, and remove the solvent , to obtain a translucent hard solid. Its infrared spectroscopic analysis see figure 1 , for thermogravimetric analysis see...

Embodiment 2

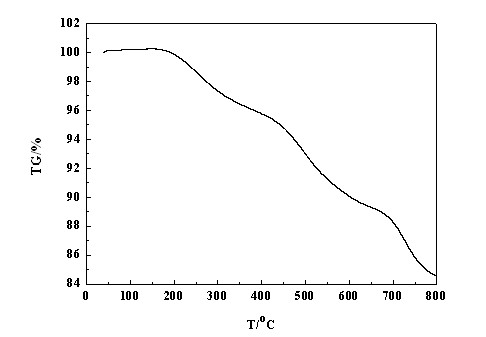

[0042] Same as Example 1, the Ph / R value is fixed at 0.1, and the R / Si value is changed to 1.3. Add 41.86 g of methyltrichlorosilane, 8.772 g of dimethyldichlorosilane, 9.932 g of methylphenyldichlorosilane and 90.846 g of xylene into a 1000 mL four-neck flask, keep stirring fully under an ice-water bath, drop Add a mixture of water and acetone, wherein the mass of water is 155.52 g, and the mass of acetone is 77.76 g. Keep for 3~5 h to complete the dropwise addition, and stir well to continue the reaction for 2 h. After the reaction, the upper oil layer was washed with water until neutral to obtain a white turbid prepolymer. Concentrate the prepolymer under reduced pressure at 120 °C to a solid content of 50-70 %, add 0.2422 g of stannous octoate condensation catalyst (the amount is 0.4 % of the total mass of the monomer) at 150 °C, heat-preserve polycondensation, and remove the solvent , to obtain a translucent hard solid. Thermogravimetric analysis see image 3 .

Embodiment 3

[0044] Same as Example 1, the Ph / R value is fixed at 0.1, and the R / Si value is changed to 1.4. Add 35.88 g of methyltrichlorosilane, 13.416 g of dimethyldichlorosilane, 10.696 g of methylphenyldichlorosilane and 89.988 g of xylene into a 1000 mL four-neck flask, keep stirring fully under an ice-water bath, drop Add a mixture of water and acetone, wherein the mass of water is 149.76 g, and the mass of acetone is 74.88 g. Keep for 3~5 h to complete the dropwise addition, and stir well to continue the reaction for 2 h. After the reaction, the upper oil layer was washed with water until neutral to obtain a white turbid prepolymer. Concentrate the prepolymer under reduced pressure at 120 °C to a solid content of 50-70 %, add 0.24 g of stannous octoate condensation catalyst (the amount is 0.4 % of the total mass of monomers) at 150 °C, heat-preserve polycondensation, and remove the solvent , to obtain a translucent hard solid. Thermogravimetric analysis see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com