Equipment and process for producing melamine under low pressure

A melamine and low-pressure technology, which is applied in the field of melamine production technology, can solve the problems of steam consumption, difficult treatment of filter residue, and difficult handling, so as to increase the production capacity of the device, reduce the gas circulation volume, and prolong the running time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

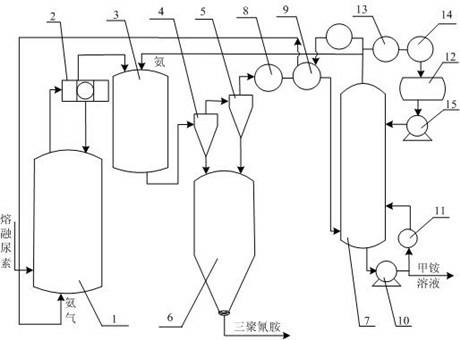

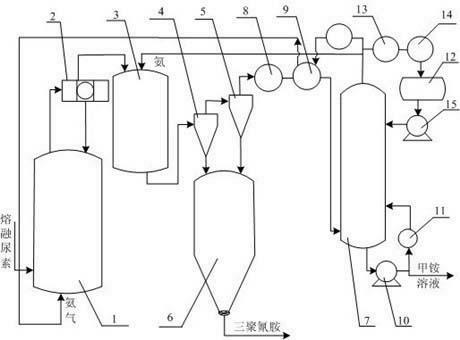

[0038] Such as figure 1 Shown, the technology of low-pressure production melamine mainly consists of the following steps.

[0039] First, the atomized molten urea is added to the reactor 1, and ammonia is used as the reaction carrier gas to pass into the reactor, and the molten salt provides the heat of reaction through the heating coil located in the reactor 1, and maintains the reactor 1 The internal temperature is 380° C., and the reaction is carried out under the conditions of a reaction pressure of 0.3 MPa.

[0040] Urea reacts in reactor 1 to generate melamine, by-product carbon dioxide and ammonia, and a small amount of melamine further reacts to generate deamination products of melamine. At this reaction temperature, ammonia, carbon dioxide, melamine, and deamination products are all gaseous.

[0041] What the reactor 1 of the present invention adopts is a fluidized bed reactor. In order to facilitate the reaction, a catalyst is also added in the reaction process. T...

Embodiment 2

[0052] Such as figure 1 Shown, the technology of low-pressure production melamine mainly consists of the following steps.

[0053] First, the atomized molten urea is added to the reactor 1, and ammonia is used as the reaction carrier gas to pass into the reactor, and the molten salt provides the heat of reaction through the heating coil located in the reactor 1, and maintains the reactor 1 The internal temperature is 385° C., and the reaction is carried out under the conditions of a reaction pressure of 0.6 MPa.

[0054] Urea reacts in reactor 1 to generate melamine, by-product carbon dioxide and ammonia, and a small amount of melamine further reacts to generate deamination products of melamine. At this reaction temperature, ammonia, carbon dioxide, melamine, and deamination products are all gaseous.

[0055] What the reactor 1 of the present invention adopts is a fluidized bed reactor. In order to facilitate the reaction, a catalyst is also added in the reaction process. T...

Embodiment 3

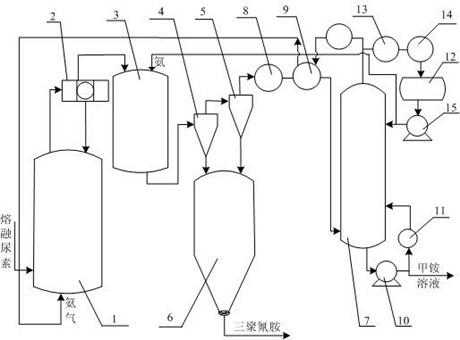

[0066] Such as figure 2 Shown, the technology of low-pressure production melamine mainly consists of the following steps.

[0067] First, the atomized molten urea is added to the reactor 1, and ammonia is used as the reaction carrier gas to pass into the reactor, and the molten salt provides the heat of reaction through the heating coil located in the reactor 1, and maintains the reactor 1 The internal temperature is 390° C., and the reaction is carried out under the conditions of a reaction pressure of 1.2 MPa.

[0068] Urea reacts in reactor 1 to generate melamine, by-product carbon dioxide and ammonia, and a small amount of melamine further reacts to generate deamination products of melamine. At this reaction temperature, ammonia, carbon dioxide, melamine, and deamination products are all gaseous.

[0069] What the reactor 1 of the present invention adopts is a fluidized bed reactor. In order to facilitate the reaction, a catalyst is also added in the reaction process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com