Laser preparation method of lanthanum molybdate based oxygen ion conductor

An ion conductor, lanthanum molybdate technology, which is applied in the field of laser preparation of lanthanum molybdate-based oxygen ion conductors, can solve the problems of increased conductivity, complex process, and long cycle, and achieve high density, simple process, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

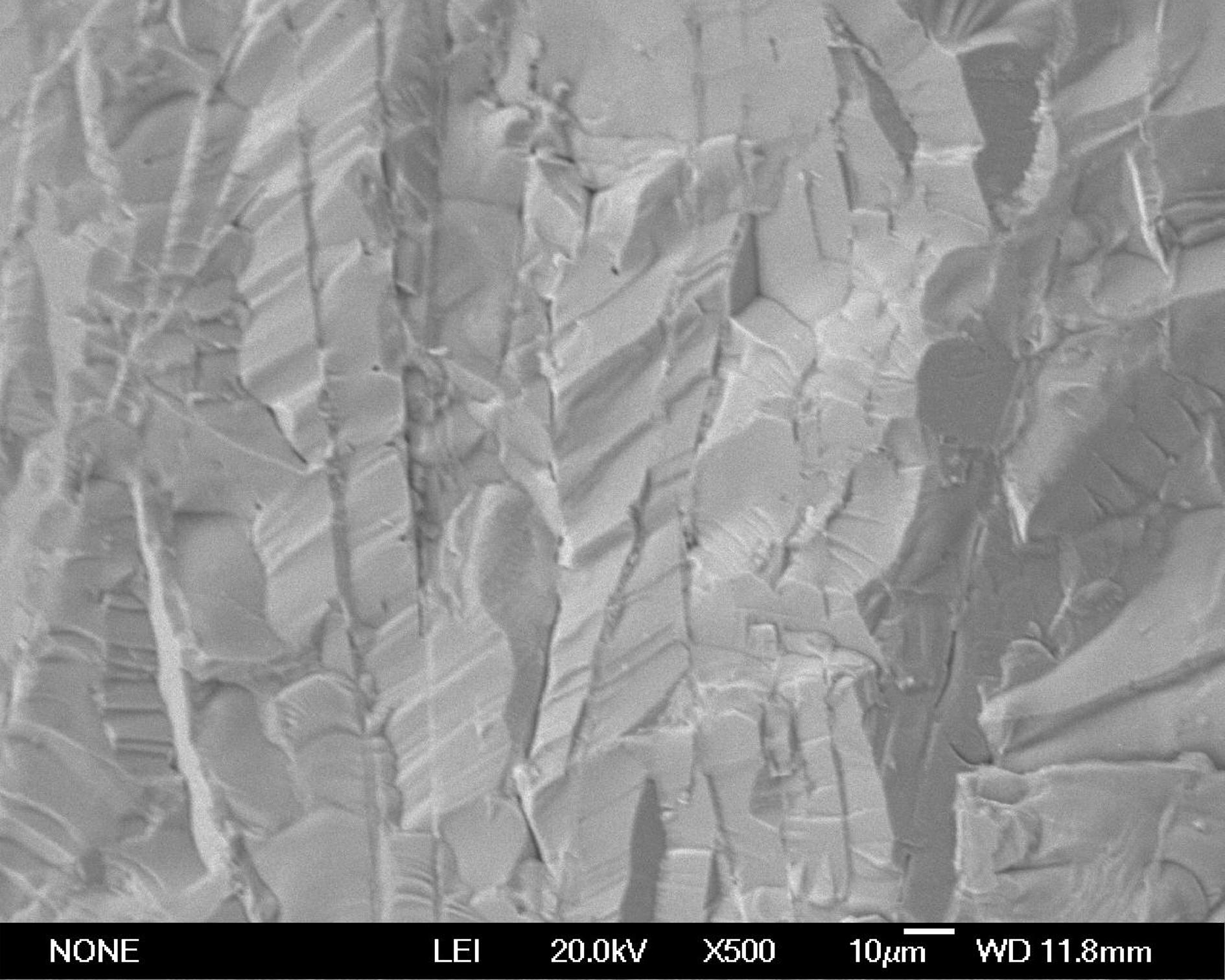

Image

Examples

Embodiment 1

[0026] La 2 Mo 0.8 W 1.2 o 9 The preparation steps are as follows:

[0027] 1) before weighing La 2 o 3 Put it in a high-temperature furnace and burn it at 800 °C for 2 hours to remove the hydroxide and carbonate components.

[0028] 2) will La 2 o 3 、MoO 3 、WO 3 Mixed according to the molar ratio of 1:0.8:1.2, then mixed with absolute ethanol, sealed in an agate jar equipped with agate balls, ball milled for 4 h with a high-energy ball mill, and the ball mill speed was 220 rpm, then the sample was taken out and placed in a dry box Dry for 5 h in a drying oven at 150 °C. The dried mixed powder was compacted under a pressure of 40 MPa for a dwell time of 60 s to obtain a green body with a diameter of 14 mm and a thickness of 2 mm.

[0029] 3) The sample body was placed in a crucible, covered with a lid, and placed in a high-temperature tube furnace. The high-temperature furnace was set to heat up to a calcination temperature of 590 °C at a rate of 5 °C / min, and pre-...

Embodiment 2

[0034] The laser power used is 700 W, and the irradiation time for each surface is 60 s. Others are the same as in Example 1. The conductivity of the prepared samples in the range of 500-800 ℃ was tested by AC impedance spectroscopy in air atmosphere and the phase composition was analyzed by X-ray diffraction. Corresponding in the XRD spectrum peak position and embodiment 1, illustrate also can prepare pure La under this condition 2 Mo 0.8 W 1.2 o 9 , a cubic structure at room temperature. The relative density of the sample is 99.2%, and the electrical conductivity is shown in Table 1.

Embodiment 3

[0036] La 2 o 3 、MoO 3 、WO 3 Proportioning according to the molar ratio of 1:1.0:1.0, other are the same as embodiment 2. Corresponding in the XRD spectrum peak position and embodiment 1, illustrate that pure La can be prepared under this condition 2 Mo 1.0 W 1.0 o 9 , a cubic structure at room temperature. The relative density of the sample is 99.3%, and the electrical conductivity is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com