Method for removing arsenic by using Fe (II) and Mn (II) in underground water

A groundwater and determination method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problems of not considering the full utilization of composite oxidizing flocculants, high cost of chemicals, and difficulty in application , to achieve the effect of long-term stability of arsenic removal, easy operation and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

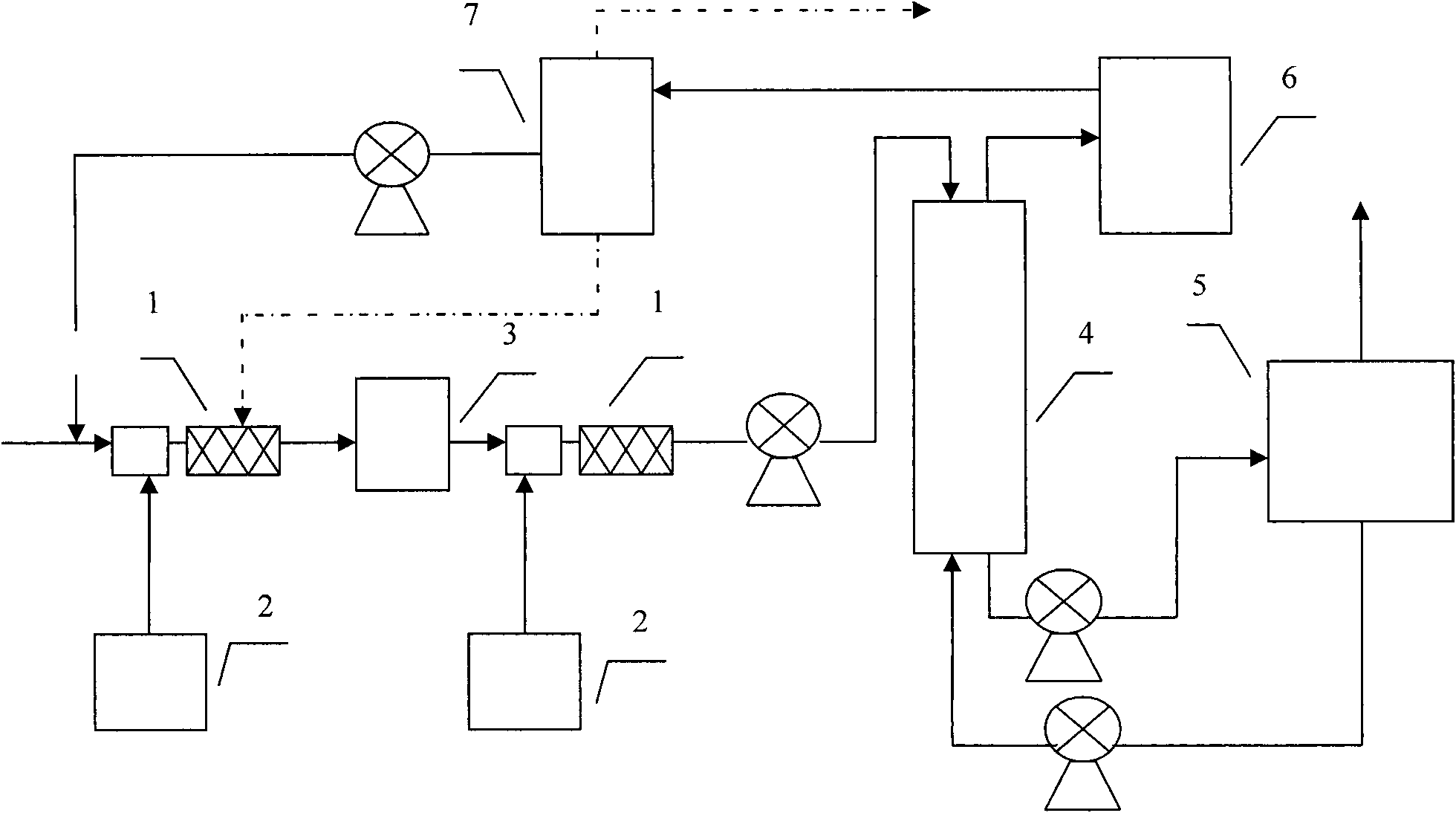

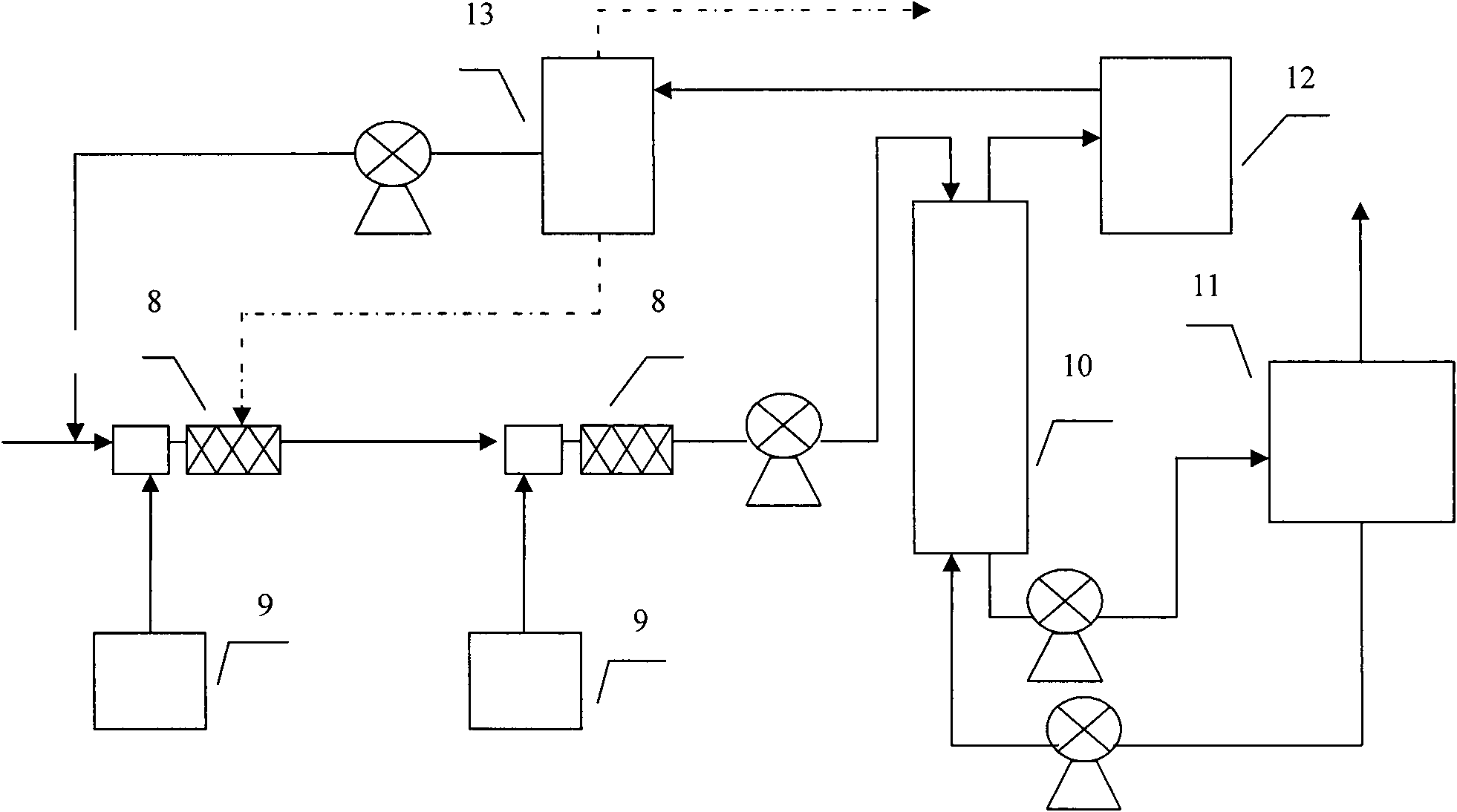

Method used

Image

Examples

Embodiment 1

[0045] In this example, the raw water has a turbidity of 2.1 NTU, contains 50 μg / L of As(III), contains 1.2 mg / L of Fe(II), and contains 0.65 mg / L of Mn(II). The filter unit used is a contact filter tank, and the backwash wastewater treatment unit used is a gravity hydrocyclone separator.

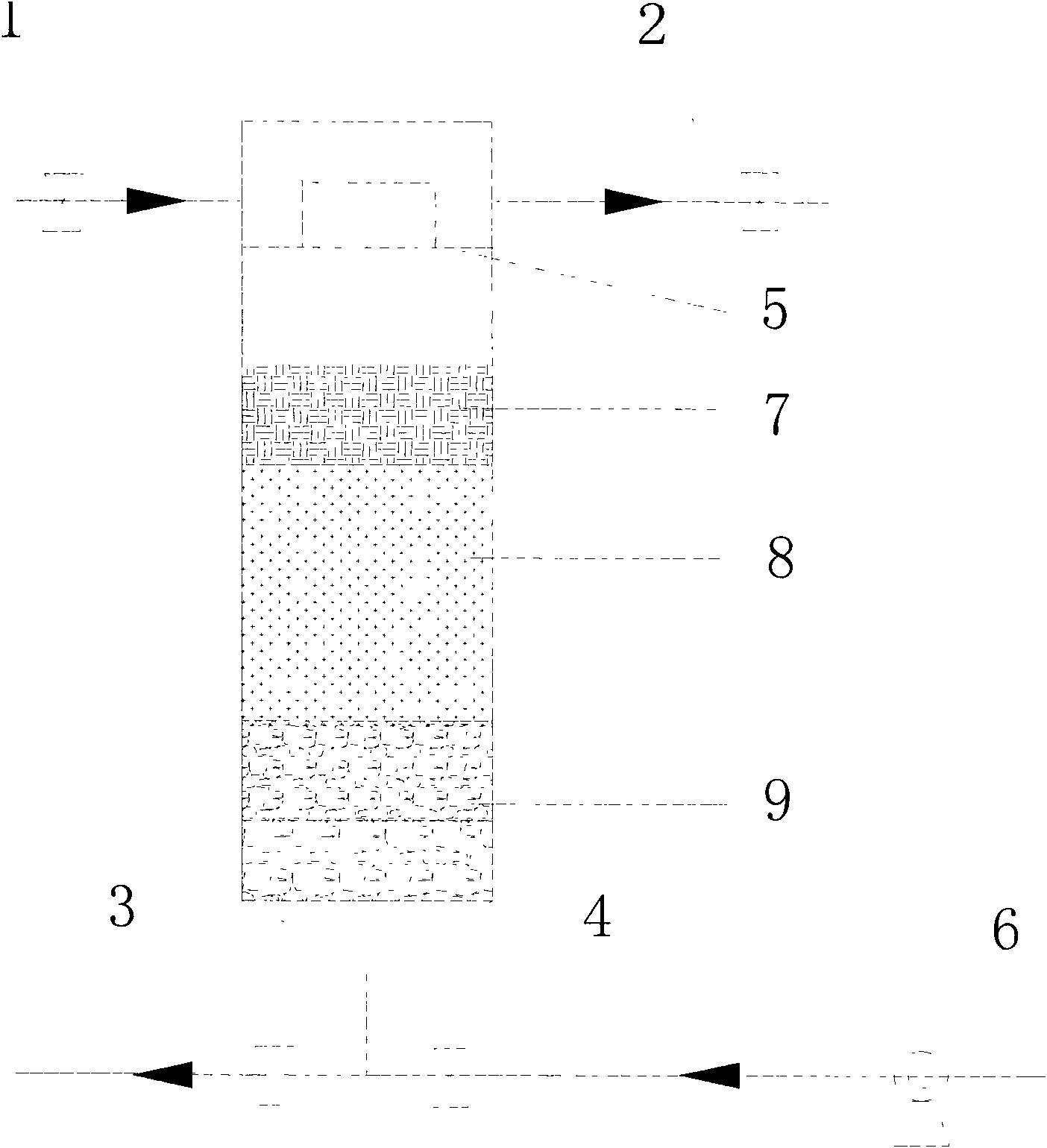

[0046] The composite agent added in the pipeline mixer is composed of 0.3mg / L potassium permanganate and 2mg / L ferric chloride, and the residence time of the arsenic-containing groundwater in the pipeline is 30 seconds after adding the medicine; Physical and chemical processes such as flocculation and adsorption. After that, enter the contact filter tank for filtration, wherein the upper layer of the filter bed is an anthracite filter layer with a thickness of 40cm (particle size 1-2mm), the middle layer is a quartz sand filter layer with a thickness of 80cm (particle size 0.6-0.9mm), and the lower layer is The supporting layer with a thickness of 100cm has a filtration rate of 7.5m / h; aft...

Embodiment 2

[0048] In this example, the raw water has a turbidity of 7.9 NTU, contains 30 μg / L of As(III), contains 2.31 mg / L of Fe(II), and contains 1.25 mg / L of Mn(II). The filter unit used is a contact filter tank, and the backwash wastewater treatment unit used is an ultrafiltration membrane reactor.

[0049] The composite agent added in the pipeline mixer is composed of 0.2mg / L potassium permanganate and 1mg / L ferric chloride, and the residence time of the arsenic-containing groundwater in the pipeline is 45 seconds after adding the medicine; Physical and chemical processes such as flocculation and adsorption. After that, enter the contact filter tank for filtration, wherein the upper layer of the effective filter layer is a porous coke filter layer (1.5-2 mm in particle size) with a thickness of 50 cm, and the lower layer is a manganese sand filter layer (0.6-0.9 mm in particle size) with a thickness of 100 cm. The filtration rate is 10m / h, and the arsenic-containing water undergoe...

Embodiment 3

[0051] In this example, the raw water has a turbidity of 2.3 NTU, contains 20 μg / L of As(III), contains 0.45 mg / L of Fe(II), and contains 0.21 mg / L of Mn(II). The filter unit used is a contact filter tank, and the backwash wastewater treatment unit used is an ultrafiltration membrane reactor.

[0052] The composite agent added in the pipeline mixer is composed of potassium permanganate of 0.042mg / L and ferric chloride of 1.16mg / L, and the residence time of the arsenic-containing groundwater in the pipeline is 30 seconds after the dosing; Physical and chemical processes such as microflocculation and adsorption. After that, enter the contact oxidation tank for filtration, wherein the upper layer of the effective filter layer is a porous coke filter layer (1.5-2 mm in particle size) with a thickness of 20 cm, and the lower layer is a quartz sand filter layer (0.6-0.9 mm in particle size) with a thickness of 100 cm. The filtration rate is 10m / h, and the arsenic-containing water u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com