High-conductivity graphene material with low-temperature gas-phase reduction and preparation method thereof

A graphene, high-conductivity technology, applied in the field of graphene material preparation, can solve problems such as high cost, damage to graphene structure, environmental pollution, etc., and achieve the effects of high-efficiency reduction, good mechanical strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the low-temperature gas-phase reduction high-conductivity graphene material of the present invention specifically comprises: adopting multi-temperature zone heating furnace equipment, placing the raw material graphene oxide at the low-temperature end, and placing the solid-phase reducing agent at the high-temperature end or from the high-temperature end Introduce a gas-phase reducing agent; use a mechanical pump to extract the background vacuum to a certain level, for example, to 0.5Pa-10Pa, stop vacuuming, and seal; then start to heat the two ends of the heating furnace in the multi-temperature zone to the required temperature, for example, The low temperature zone is heated to 50-500°C, and the high temperature zone is heated to 400-1200°C. After a certain period of time, the heating is stopped, and it is naturally cooled to room temperature to obtain a highly conductive graphene material. The reaction holding time can be 30-600min.

[0033]T...

Embodiment 1

[0050] The sample to be reduced is graphene oxide paper that has been vacuum filtered, with a thickness of 5 microns and a density of 1.8g / cm 3 , 10cm in diameter. The reducing agent is high-purity Al powder; the raw material graphene oxide paper is placed at the low-temperature end of the multi-temperature zone heating furnace, and the high-purity Al powder is placed at the high-temperature end. The temperature at the high-temperature end is 700°C, and the temperature at the low-temperature end is 100°C. Use a mechanical pump to extract the background vacuum to about 1Pa, stop vacuuming, and seal. Start to heat the two ends of the heating furnace in the multi-temperature zone to the required temperature respectively, keep the heat for 3 hours, stop heating, and let the furnace cool naturally.

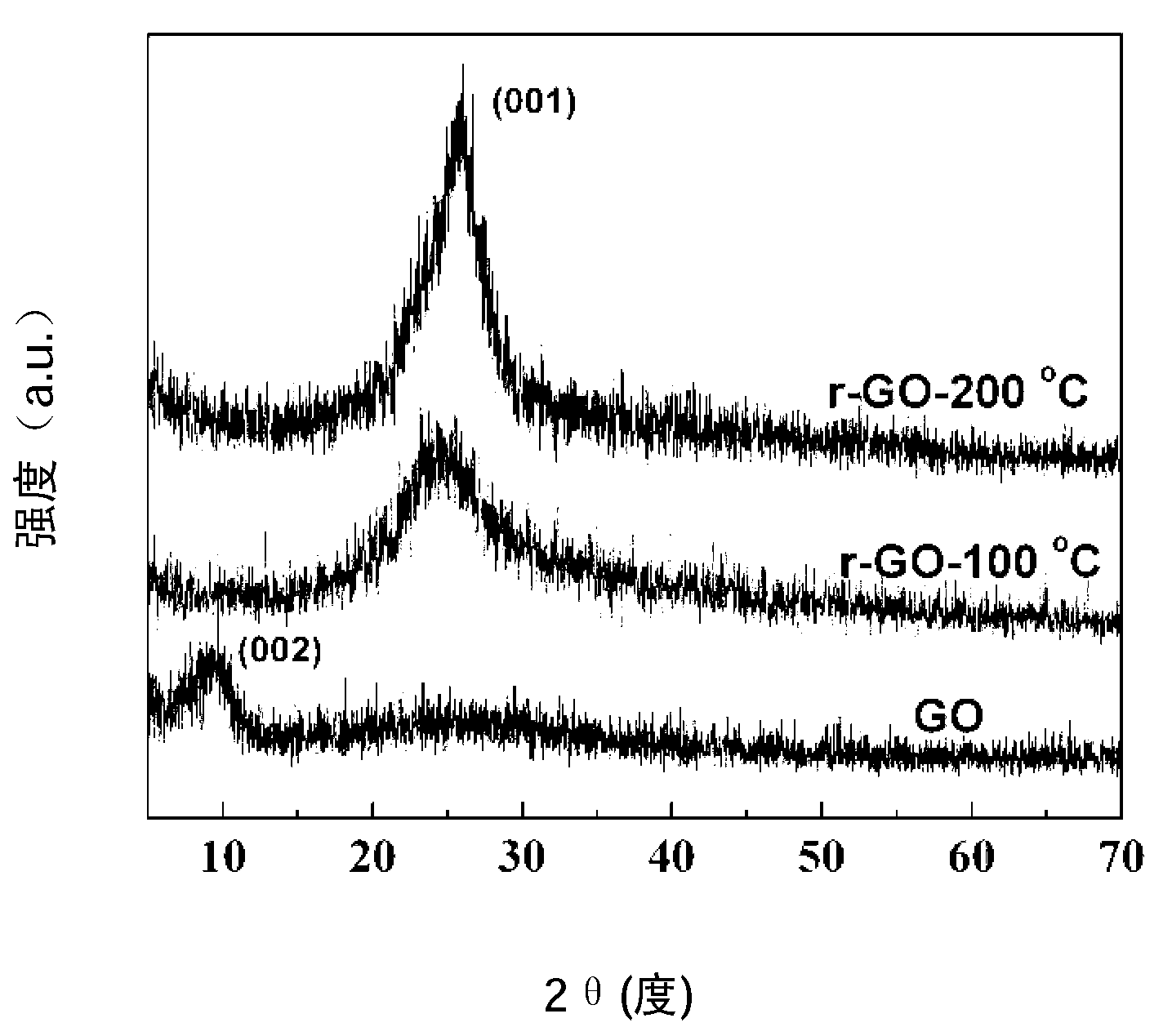

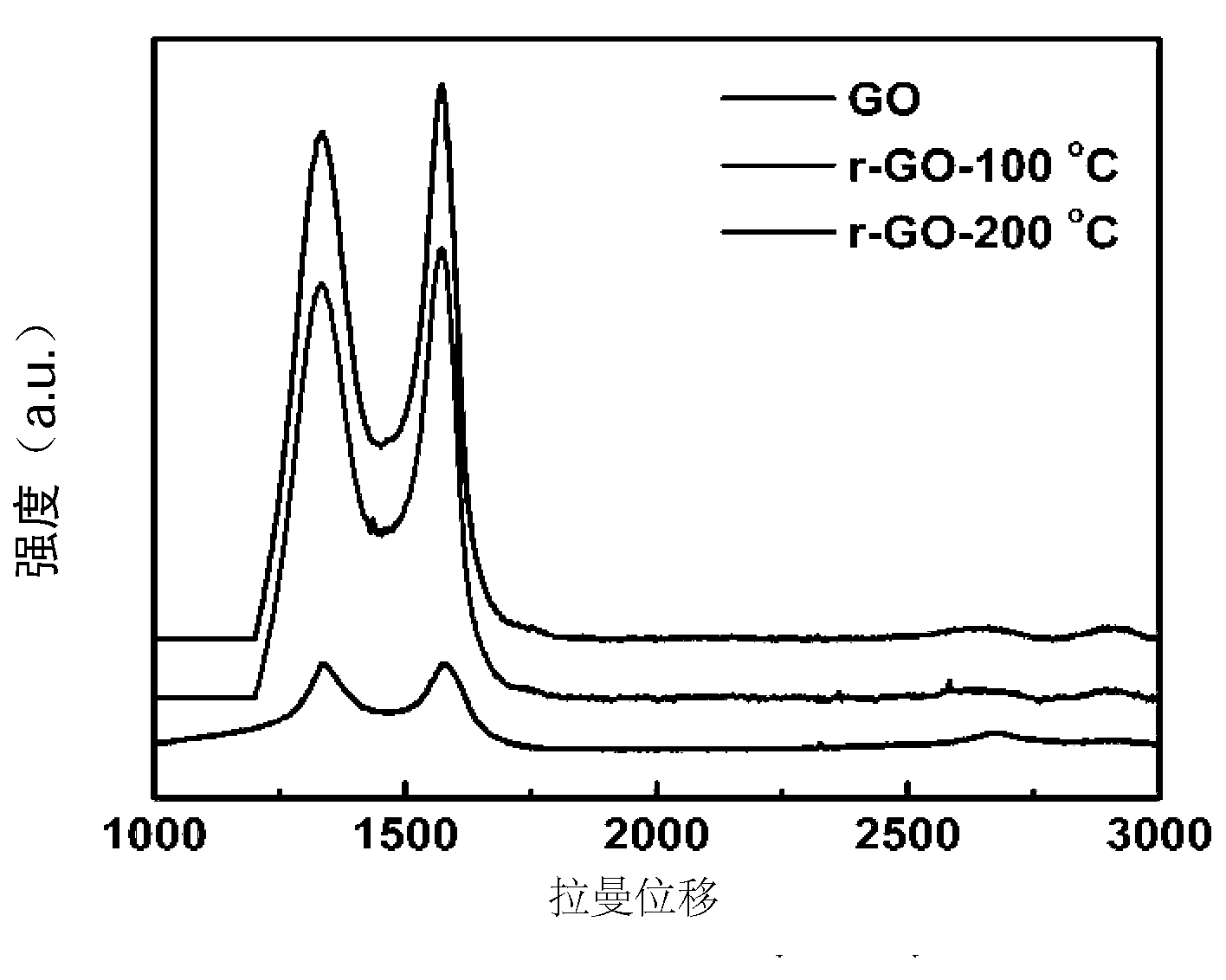

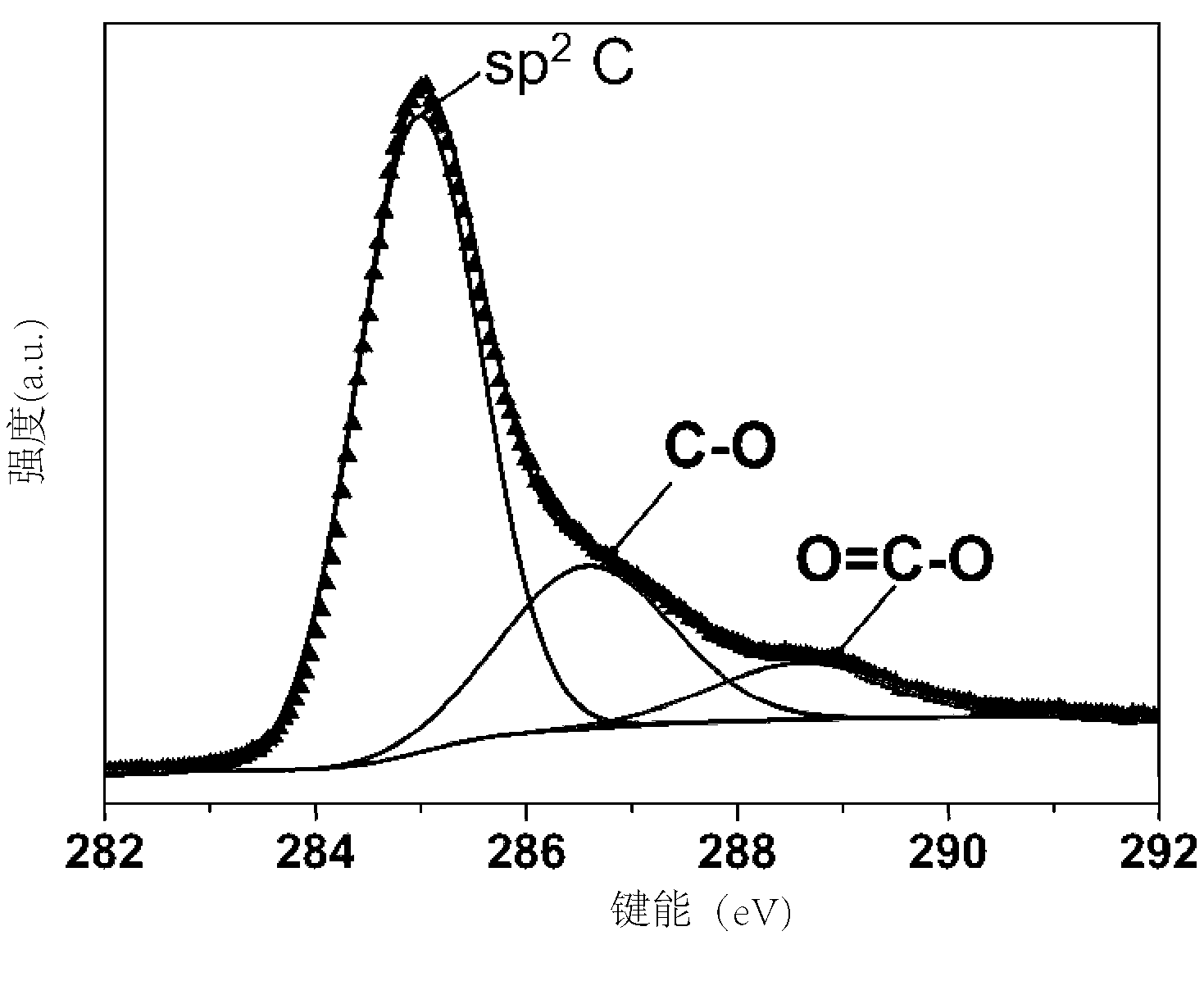

[0051] Morphology and structure characterization of graphene

[0052] The graphene structure was characterized by Raman spectroscopy (Renishaw invia Raman Microscope, excitation wave...

Embodiment 2

[0055] The sample to be reduced is graphene oxide paper that has been vacuum filtered, with a thickness range of 5 microns and a density range of 1.8 g / cm 3 , 10cm in diameter. The reducing agent is high-purity Al powder; the raw material graphene oxide paper is placed at the low-temperature end of the multi-temperature zone heating furnace, and the high-purity Al powder is placed at the high-temperature end. The temperature at the high-temperature end is 700°C, and the temperature at the low-temperature end is 200°C. Use a mechanical pump to extract the background vacuum to about 1Pa, stop vacuuming, and seal. Start to heat the two ends of the heating furnace in the multi-temperature zone to the required temperature respectively, keep the heat for 3 hours, stop heating, and let the furnace cool naturally.

[0056] The X-ray diffraction and Raman spectra of the reduced graphene are still shown in figure 1 and figure 2 . As shown in the figure, compared with Example 1, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com