Preparation method of nano solar battery based on CuS quasi one-dimensional nanostructure

A technology of solar cells and nanostructures, which is applied in the field of preparation of nano solar cells, can solve the problems of restricting widespread use, few researches on nano solar cells, poor controllability, etc., and achieves the effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preparation method of the nano solar cell based on the CuS quasi-one-dimensional nanostructure of the present invention will be described in detail below in conjunction with the accompanying drawings, and the non-limiting examples are as follows.

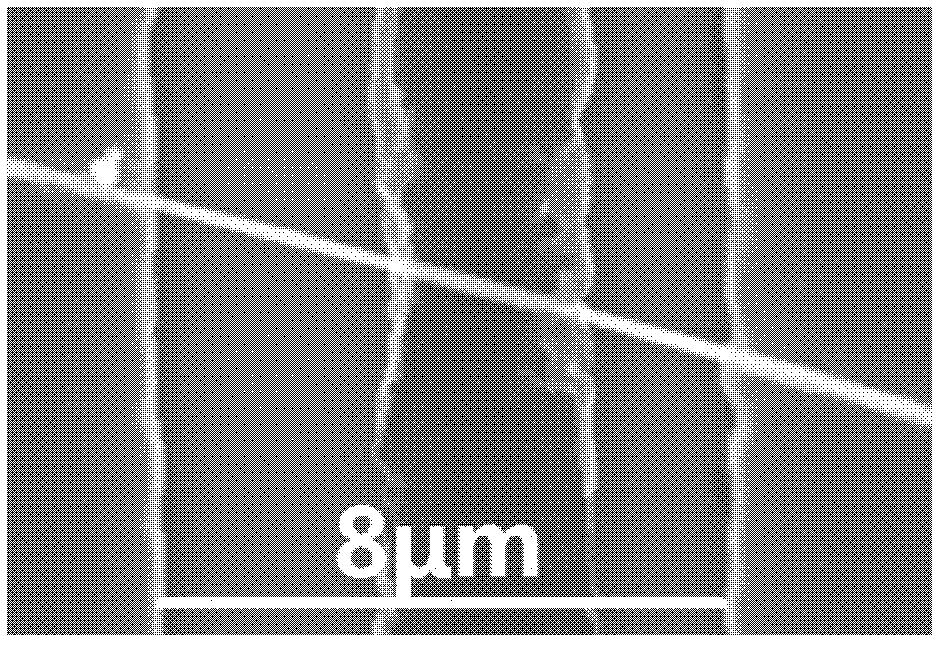

[0021] 1. Ultrasonic dispersion of CuS nanotubes (J.Mater.Chem., 2006, 16, 3326-3331, diameters in the range of 60-160nm and lengths of more than 40μm)3 synthesized by the conventional liquid-phase sacrificial template method in the absence of A suspension is formed in water and ethanol, and the suspension is sucked up with a glue-tip dropper and dropped on a clean SiO2 layer with a thickness of 300nm. 2 On the silicon wafer 1 of the insulating layer 2, the uniform and horizontal dispersion of CuS nanotubes 3 on the insulating layer 2 is realized, and the dispersion density is about 5-12 / mm by electron microscope observation 2 . After uniform spin-coating of positive photoresist, UV exposure and development are carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com