Automatic feeding machine for Monofilament mattress

A technology of automatic feeding and brown silk, which is applied in the production of loose filling materials, household utensils, furniture covers, etc., can solve problems such as difficult to guarantee product quality and output, low efficiency, too much and too little, etc., to achieve Significant social and economic benefits, improve quality and aesthetics, and save production labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

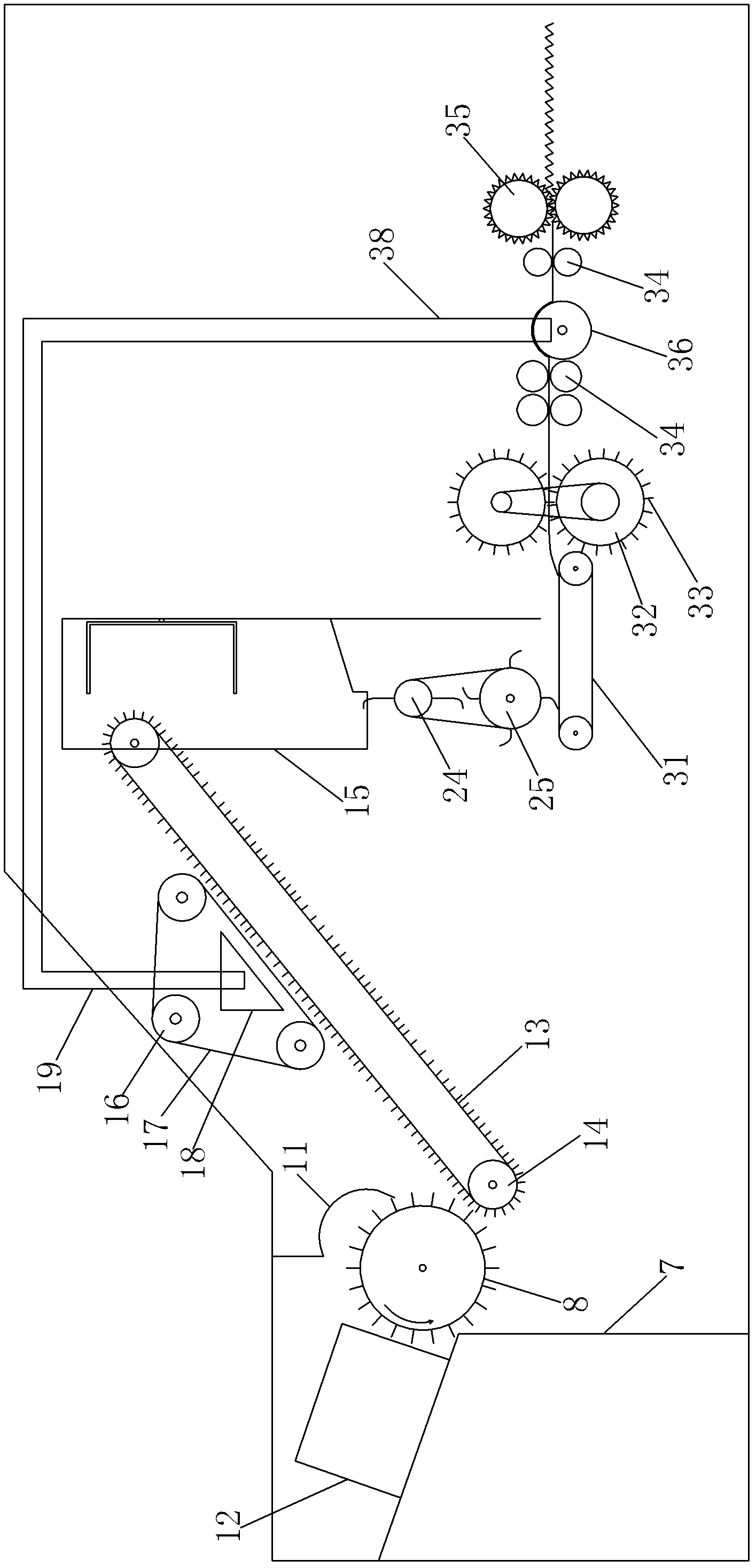

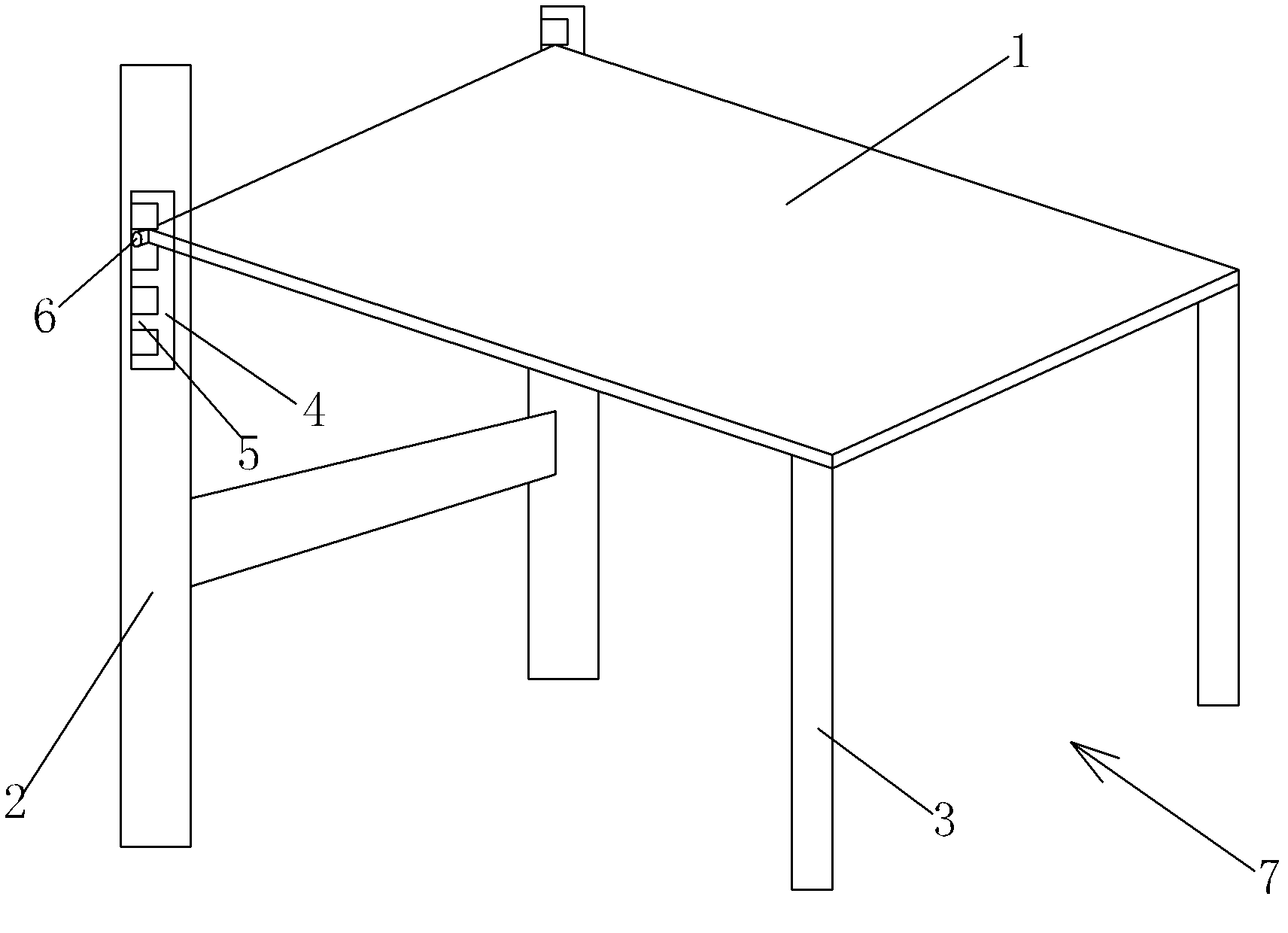

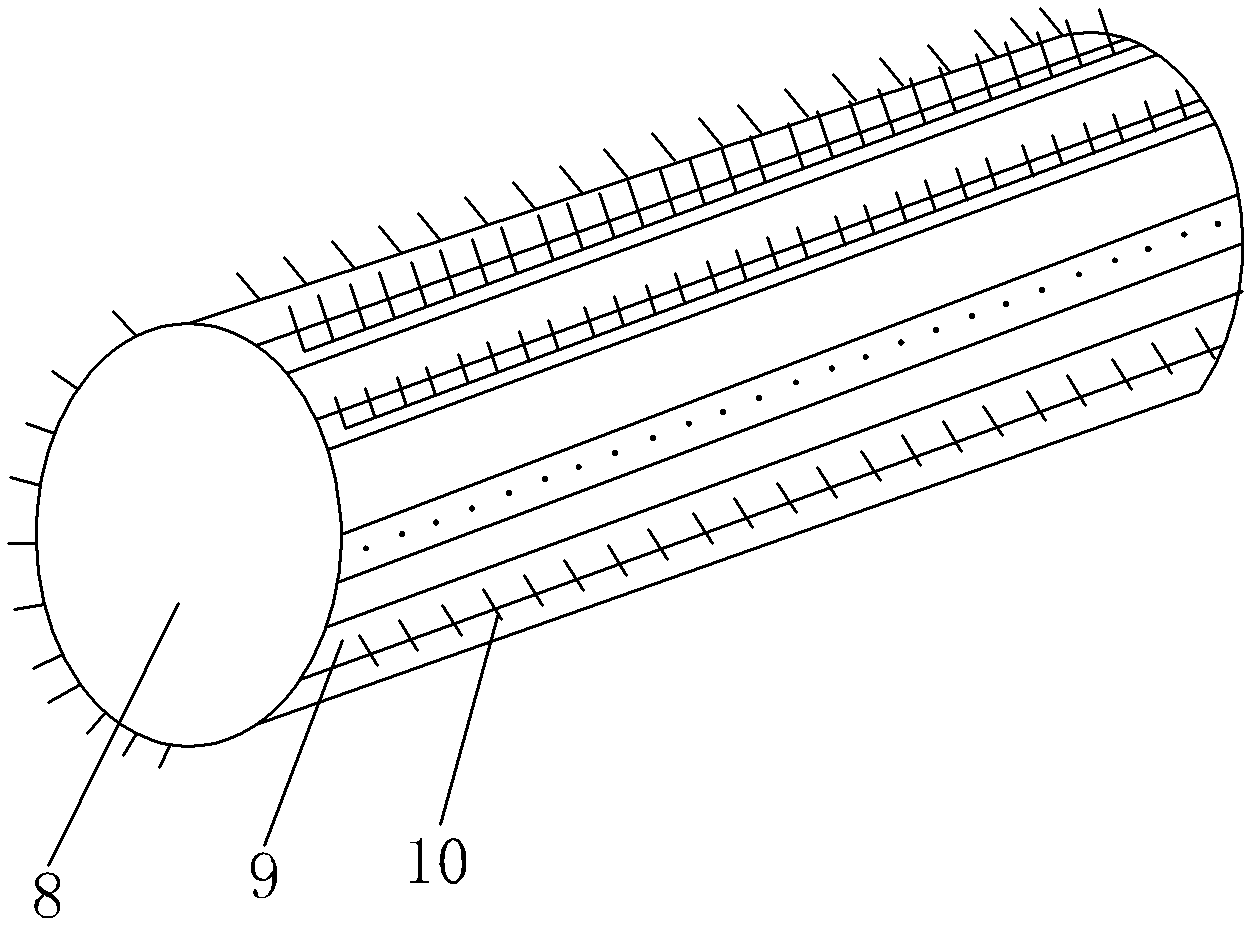

[0021] Embodiment: a kind of brown silk mattress automatic feeder, as figure 1 Shown, comprise brown silk bag feeder 7, band tooth conveyer belt 13, feed material box 15; Described brown silk bag feeder 7 is as figure 1 , figure 2 As shown, it includes a pallet 1 with a high upper end and a low lower end that is inclined, the upper end of the pallet 1 is supported by two first legs 2, the lower end of the pallet 1 is fixedly provided with a second leg 3, and the first leg The leg 2 is provided with a height adjustment mechanism, and the height adjustment mechanism includes a chute 4 vertically opened on the first leg 2, and a plurality of positioning grooves 5 arranged at intervals are provided on one side of the chute 4, and the positioning The groove 5 is horizontally arranged, and one end of the positioning groove 5 communicates with the chute 4, and a pin shaft 6 is respectively arranged on the left and right sides of the upper end of the supporting plate 1, and the pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com