Electrospinning direct-writing closed-loop control system and control method

An electrospinning direct writing, closed-loop control technology, applied in printing, printing devices, etc., can solve the problem of lack of control strategies, complex mathematical and physical models, limitations of electrospinning direct writing micro-nano structure uniformity, direct writing micro-nano structure size controllable To further improve the performance and other issues, to achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

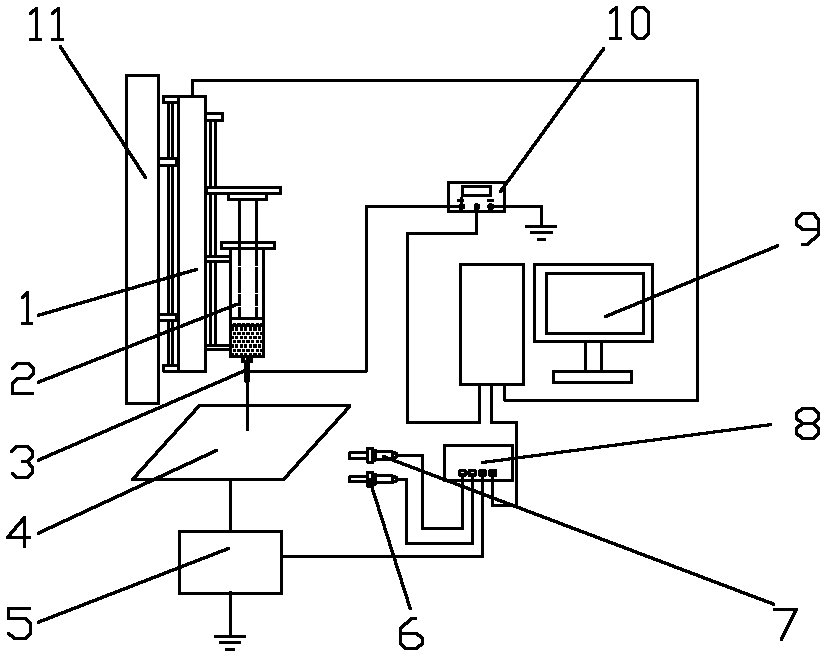

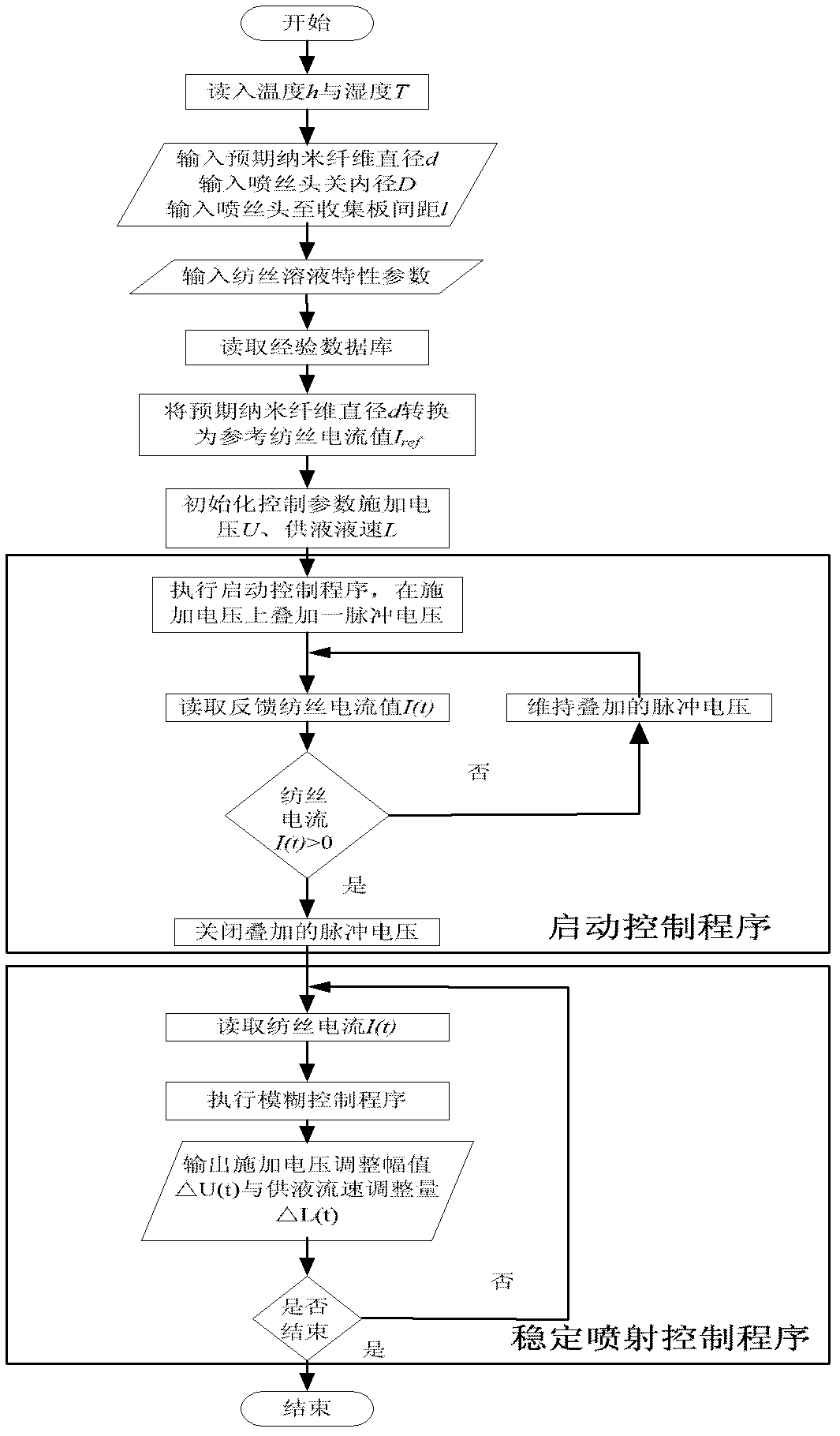

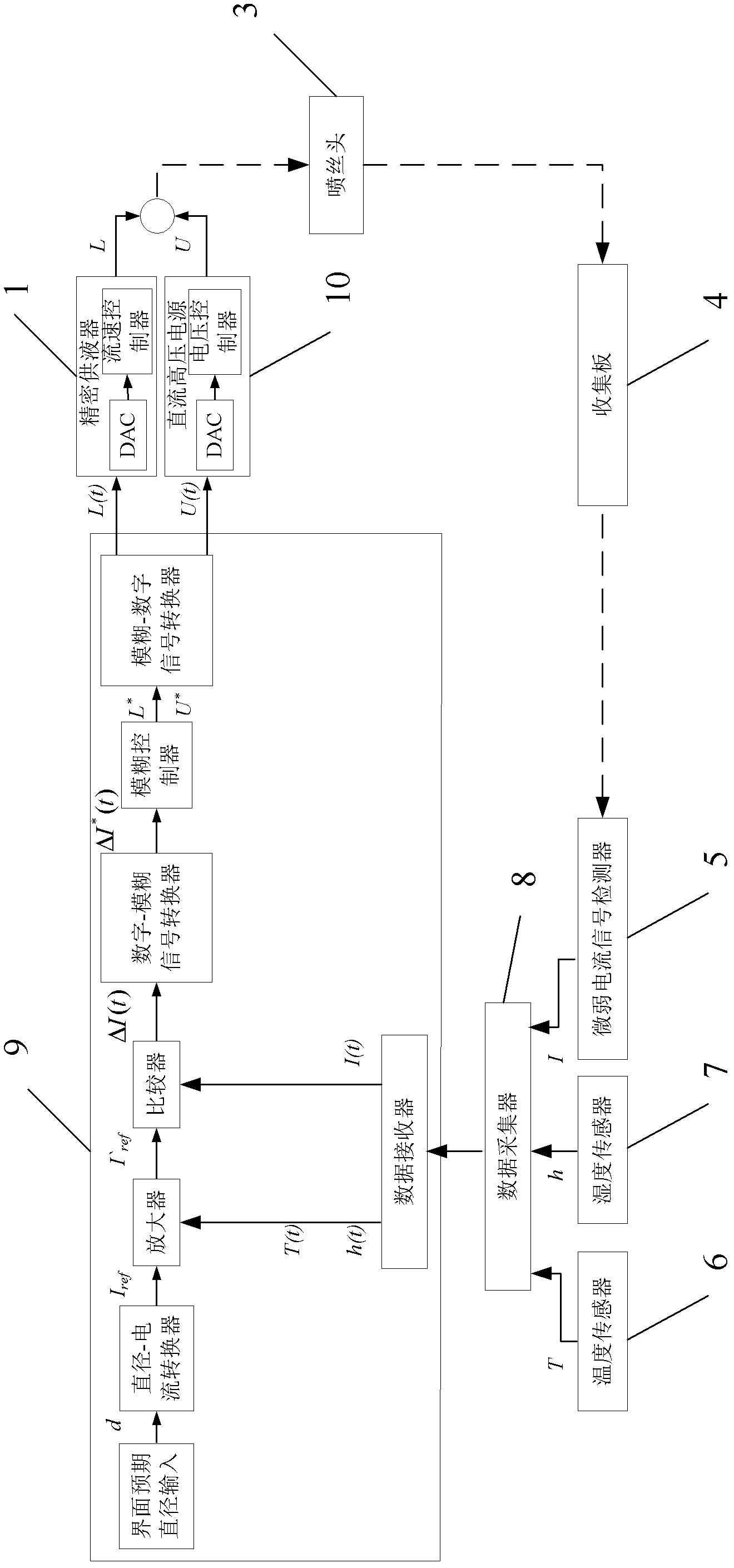

[0038] see figure 1 , the embodiment of the present invention is provided with storage tank 2, liquid feeder 1, spinneret 3, collecting plate 4, weak current detector 5, temperature sensor 6, humidity sensor 7, data collector 8, control computer 9 and direct current A high-voltage power supply 10; the liquid storage tank 2 is installed on the liquid supply device 1 and connected to the spinneret 3 through a conduit to provide a solution for the electrospinning direct writing process; the spinneret 3 is a jet injection channel; the collecting plate 4 is grounded, Used to collect nanofibers; the receiving end of the data collector 8 is connected to the weak current detector 5, the temperature sensor 6, and the humidity sensor 7 through the data line, and receives the data obtained by each detection sensing component; the weak current detector 5 is used for detection Spinning current, and the current signal is sent to the data collector 8 through the data transmission line, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com