Keratoprosthesis and preparation method thereof

A kind of artificial cornea and nanotechnology, applied in medical science, prosthesis, eye implants, etc., can solve the problem of poor compatibility between artificial cornea and tissue, achieve good biocompatibility and anti-infection, and promote rapid healing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

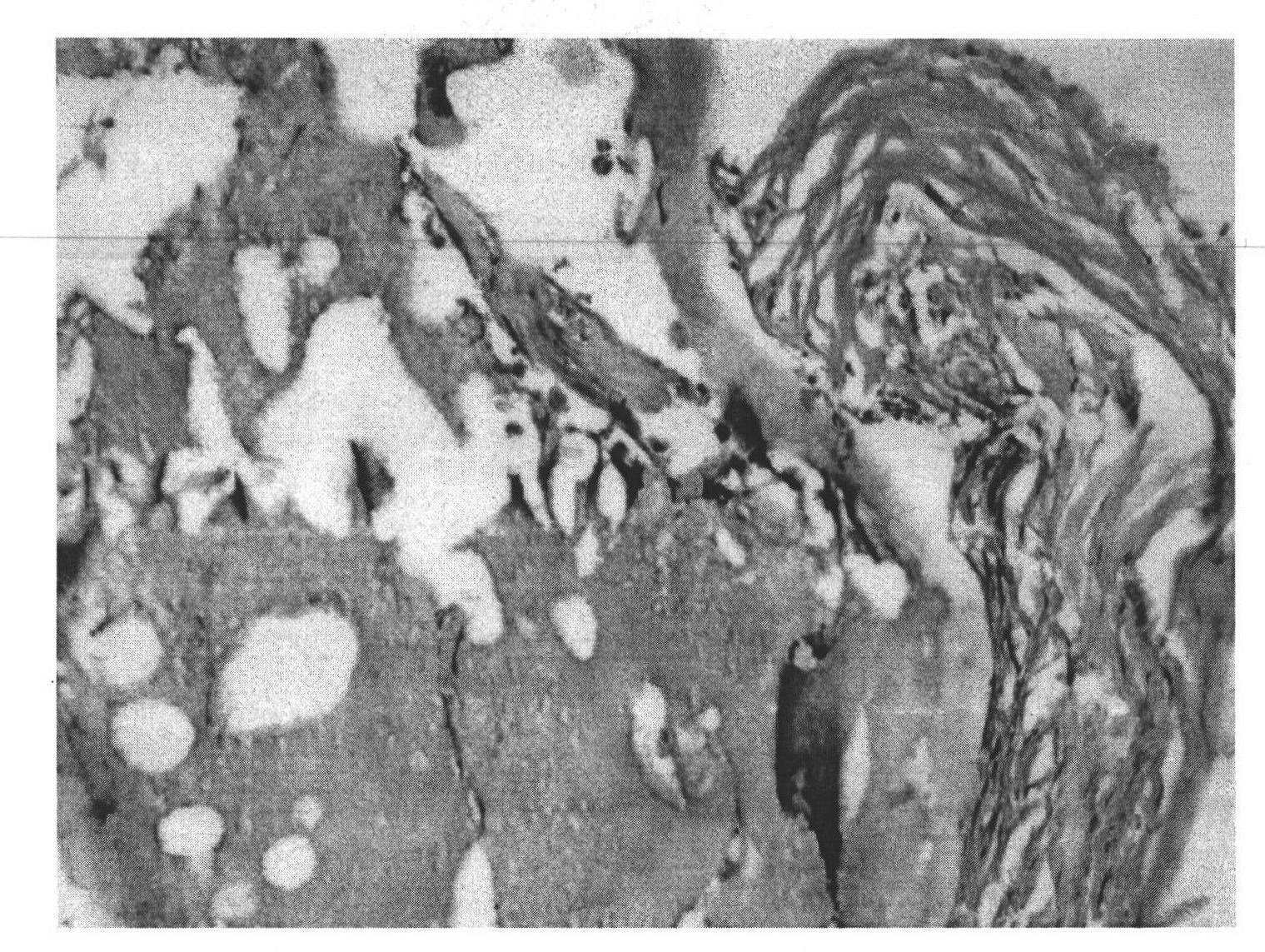

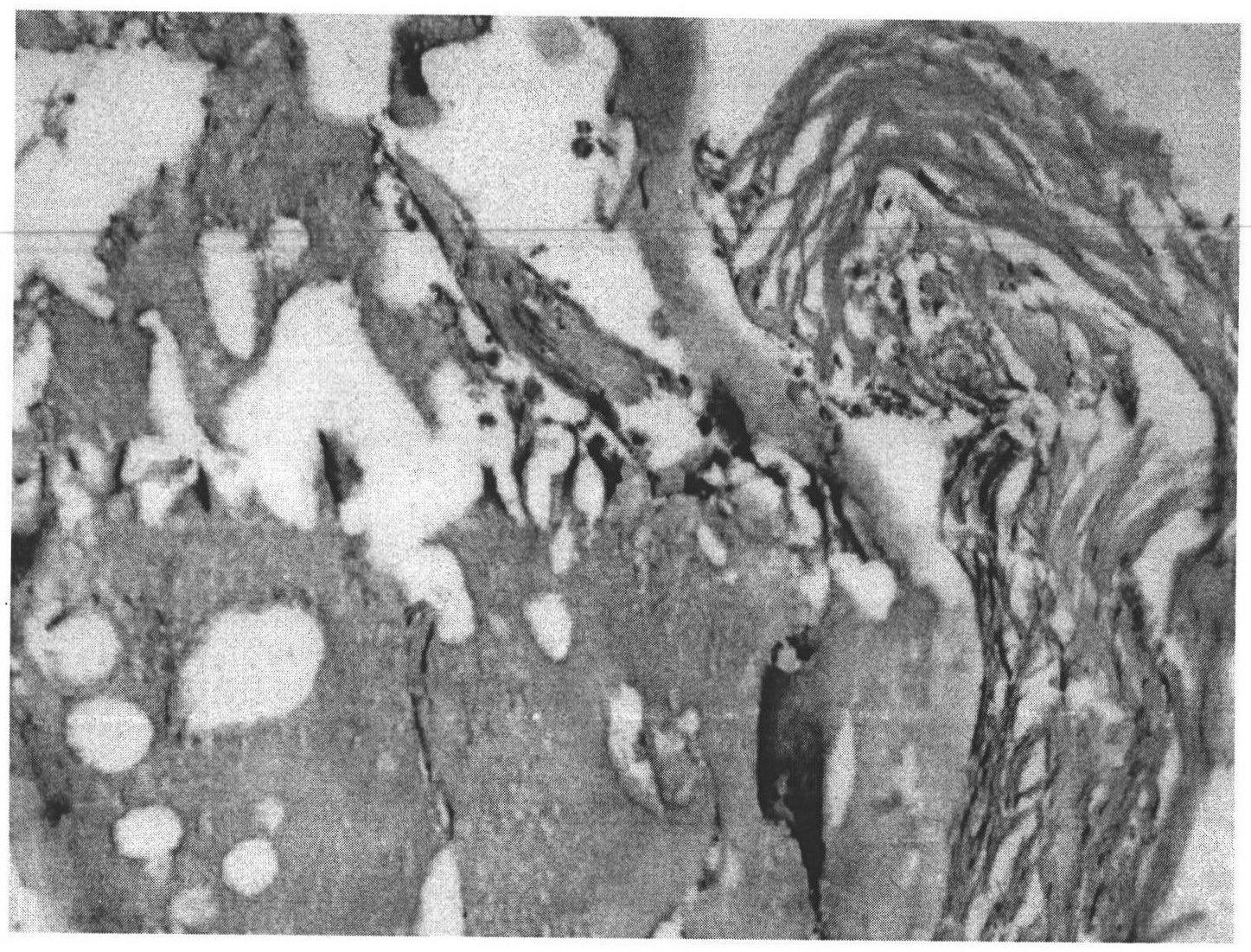

Image

Examples

preparation example Construction

[0018] The preparation method of the artificial cornea of this antibacterial activity comprises the steps:

[0019] Step 1, polyvinyl alcohol, chitosan derivative (this chitosan derivative can be 6-O-carboxymethyl chitosan, chitosan quaternary ammonium salt or chitosan), nano-phosphate, preparation Pore agent and organic solvent (dimethyl sulfoxide, DMSO for short) are mixed according to the mass ratio of 1-3:0.5-2:0.5-2:5-20:5-20, heated and stirred evenly, injected into the hollow mold, adjusting the thickness, molding, freezing at -20 to -40°C for 10-48 hours, thawing at room temperature for 2-6 hours, repeating the freezing-thawing process four times to obtain the scaffold material precursor;

[0020] Step 2. Mix polyvinyl alcohol, organic solvent and water uniformly in a mass ratio of 1-3:5-20:1-3, inject into the hollow part of the mold and spread it on the back of the scaffold material precursor to form a film Freezing at -20~-40°C for 10-48 hours, thawing at room ...

Embodiment 1

[0024] (1), mix polyvinyl alcohol, 6-O-carboxymethyl chitosan, nano tricalcium phosphate, sodium chloride and organic solvent DMSO in a mass ratio of 1:0.5:0.5:5:5, heat and stir Uniformly, pour into a hollow mold, adjust the thickness, and mold; freeze at -20°C for 48 hours, thaw at room temperature for 2 to 6 hours, repeat the freezing-thawing process four times, and obtain the scaffold material precursor. (2) Mix polyvinyl alcohol, DMSO and water uniformly in a mass ratio of 1:10:1, inject into the hollow part of the above-mentioned mold and extend it to form a film on the back of the scaffold material precursor; freeze at -20°C for 48 hours, thawing at room temperature for 2-6 hours, repeating the freezing-thawing process four times, so that the optical center part and the porous peripheral scaffold part form crosslinking, and form a non-water-permeable coating film on the back of the scaffold material precursor. (3) Soak the non-water-permeable coating film in water for 5...

Embodiment 2

[0026] (1), mix polyvinyl alcohol, 6-O-carboxymethyl chitosan, nano tricalcium phosphate, sodium chloride and organic solvent DMSO in a mass ratio of 2:0.5:1:10:15, heat and stir Uniformly, pour into a hollow mold, adjust the thickness, and mold; freeze at -20°C for 48 hours, thaw at room temperature for 2 to 6 hours, repeat the freezing-thawing process four times, and obtain the scaffold material precursor. (2) Mix polyvinyl alcohol, DMSO and water uniformly in a mass ratio of 2:10:2, inject into the hollow part of the above-mentioned mold and extend it to form a film on the back of the scaffold material precursor; freeze at -20°C for 48 hours, thawing at room temperature for 2-6 hours, repeating the freezing-thawing process four times, so that the optical center part and the porous peripheral scaffold part form crosslinking, and form a non-water-permeable coating film on the back of the scaffold material precursor. (3) Soak the non-water-permeable coating film in water for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com