Thin film transistor and manufacturing method for same, semiconductor device and manufacturing method for same, and display device

A technology of thin-film transistors and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, transistors, semiconductor devices, etc., and can solve problems such as opening contact holes at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0119]

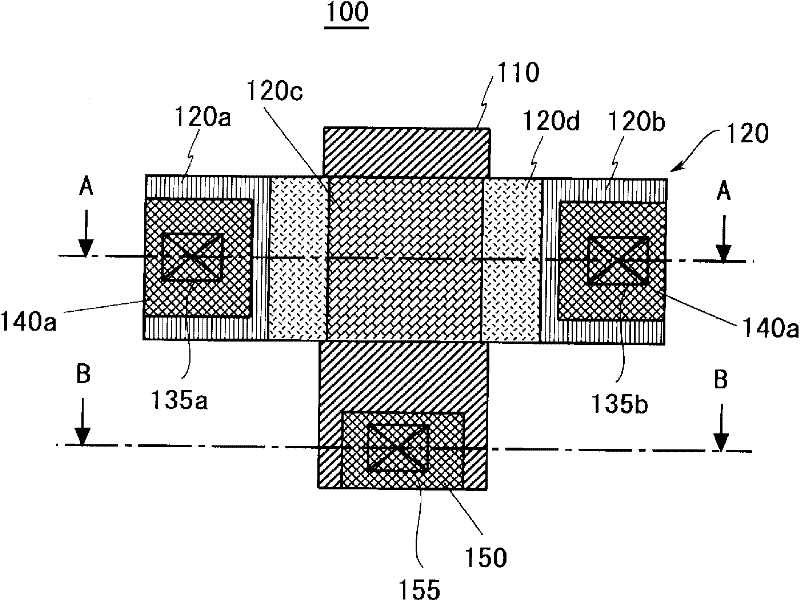

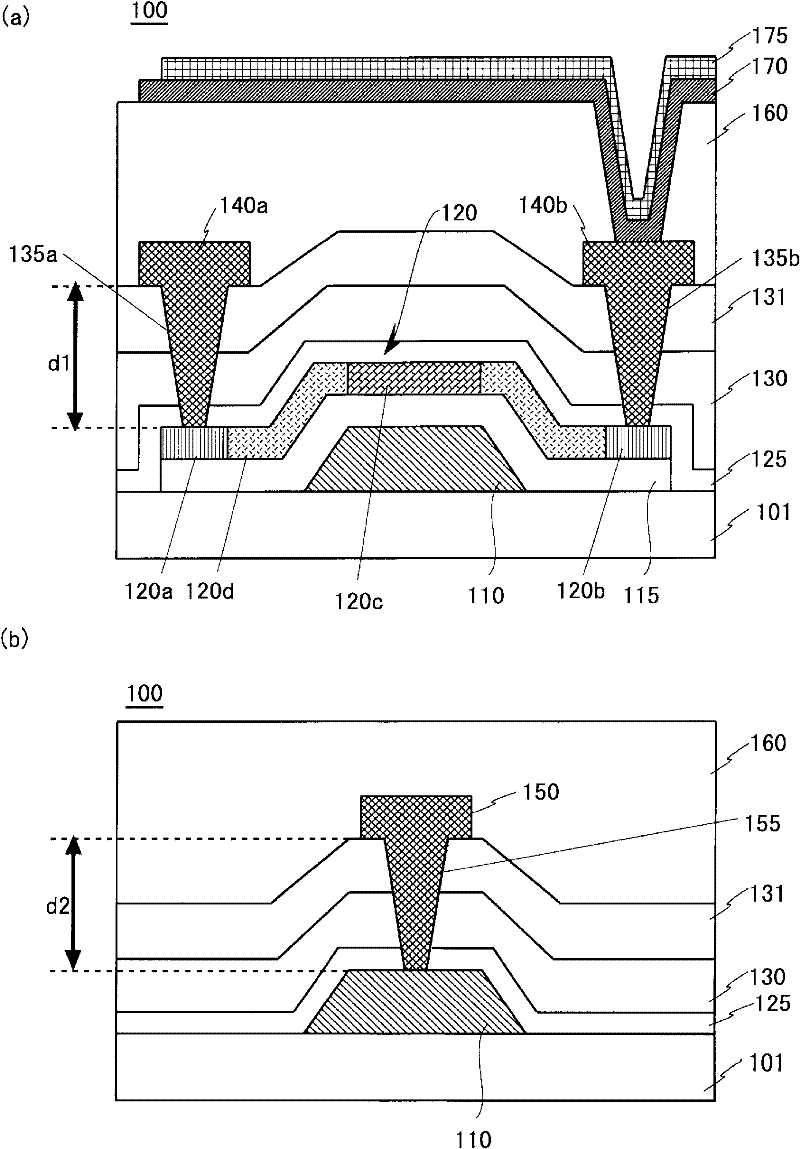

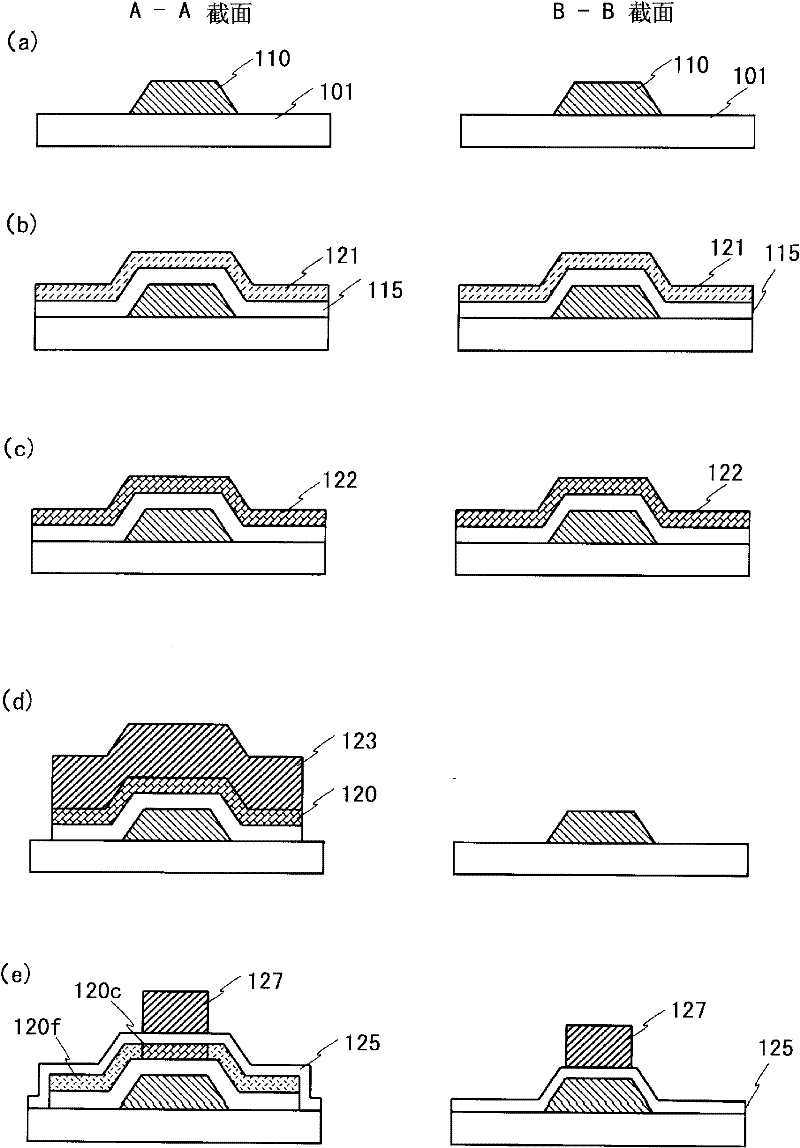

[0120] figure 1 is a plan view showing the structure of TFT 100 according to the first embodiment of the present invention, figure 2 (a) is based on figure 1 A cross-sectional view of the TFT 100 cut along the line A-A shown, figure 2 (b) is based on figure 1 A cross-sectional view of the TFT 100 cut along the line B-B shown. in addition, figure 1 In FIG. 2 , illustrations of insulating films such as gate insulating films, interlayer insulating films, and planarizing films are omitted for easier understanding. In addition, the TFT 100 is a TFT used as a switching element provided in a pixel forming portion of a liquid crystal display device.

[0121] refer to figure 1 and figure 2 The structure of TFT100 is demonstrated. like figure 1 and figure 2 As shown, a gate electrode 110 containing metal is formed on a glass substrate 101 which is an insulating substrate. A gate insulating film 115 is formed to cover a part of the surface of the gate elec...

no. 2 approach

[0143]

[0144] A plan view of TFT 200 of the second embodiment and figure 1 Since the top view of the TFT 100 of the first embodiment shown is the same, description thereof is omitted. Figure 5 (a) is based on figure 1 A cross-sectional view of the TFT 200 cut along the same cross-section as the line A-A shown, Figure 5 (b) is based on figure 1 A cross-sectional view of the TFT 200 cut along the same cross-section as the line B-B shown. In addition, in Figure 5 (a) and Figure 5 (b), for figure 2 (a) and figure 2 The same constituent elements as the constituent elements of the TFT 100 shown in (b) are denoted by the same reference numerals, and description thereof will be omitted.

[0145] like Figure 5 (a) and Figure 5 As shown in (b), unlike the case of TFT100, in TFT200, protective film 226 is further formed on the surface of gap film 125 formed on source region 120a and drain region 120b. However, if Figure 5 As shown in (b), on the gate contact re...

no. 3 approach

[0161]

[0162] In this embodiment, a description will be given of a semiconductor device 300 in which a TFT 301 having a bottom gate structure and a photodiode 302 having a light-shielding film are formed on the same glass substrate 101 . Figure 8 is a plan view showing the structure of a semiconductor device 300 according to a third embodiment of the present invention, Figure 9 (a) is based on Figure 8 A cross-sectional view of the TFT301 cut off by the line C-C shown, Figure 9 (b) is based on Figure 8 A cross-sectional view of the TFT301 cut by the line D-D shown, Figure 9 (c) is based on Figure 8 A cross-sectional view of photodiode 302 is shown cut through line E-E. In addition, in Figure 8 In FIG. 2 , illustrations of insulating films such as a gate insulating film, an interlayer insulating film, and a planarizing film are omitted for clarity.

[0163] The TFT 301 of the bottom gate structure included in the semiconductor device 300, and figure 1 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com