Method for producing piezoelectric electret functional films with piezoelectric coefficient d31

A technology of piezoelectric electret and piezoelectric coefficient, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., to achieve a simple and feasible process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 According to the following steps, the piezoelectric coefficient d 31 FEP composite film piezoelectric electret 1 .

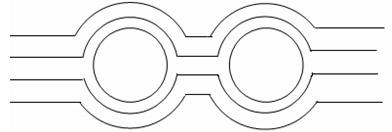

[0022] 1. Carve on a 5cm*5cm metal plate such as figure 1 In the groove structure shown, the groove depth is 1mm, the width is 1mm, and the distance between the two grooves is 0.5mm, forming a mold with the groove structure.

[0023] 2. First, put the grooved side of the mold (mould 1) facing up, and cover the surface of mold 1 with a commercially available FEP film with a thickness of 12.5 um, a rubber film with a thickness of 1mm, and A 3mm thick stainless steel plate, and then place them together on the heating plate of the heat press, at a temperature and pressure of 120 o C and 11MPa, pressurize for 1min, and finally remove the stainless steel plate and the rubber film to obtain the FEP film 1 attached to the surface of the mold 1 and having a groove structure.

[0024] 3. Using the method described in step 2 to obtain the FEP film ...

Embodiment 2

[0034] Example 2 According to the following steps, the piezoelectric coefficient d 31 FEP composite film piezoelectric electret 2 .

[0035] 1. Carve on a 5cm*5cm metal plate such as figure 1 In the groove structure shown, the groove depth is 1mm, the width is 0.5mm, and the distance between the two grooves is 0.25mm, forming a mold with the groove structure.

[0036] 2. First, put the grooved side of the mold (mould 3) upward, and cover a commercially available FEP film with a thickness of 12.5 um, a rubber film with a thickness of 1mm, and a 3mm thick stainless steel plate, and then they are placed together on the heating plate of the heat press, at a temperature and pressure of 100 o C and 11 MPa under pressure for 2 minutes, and finally remove the stainless steel plate and the rubber film to obtain the FEP film 3 attached to the surface of the mold 3 and having a groove structure.

[0037] 3. Use the method described in step 2 to obtain the FEP film 4 attached to the s...

Embodiment 3

[0044] Embodiment 3 According to the following steps, the piezoelectric coefficient d 31 FEP composite film piezoelectret3.

[0045] Steps 1 to 6 in Example 1 were repeated.

[0046] 1. Using a pin-plate corona charging system to corona charge the FEP composite film 1 . The distance between the corona needle and the surface of the FEP composite film 1 is 4cm, the corona voltage is -20kV, the charging time is 5min, and the ambient temperature is 15 o c.

[0047] 2. Vacuum vapor-deposit aluminum electrodes with a thickness of 100 nm on both sides of the FEP composite film.

[0048] The FEP composite film piezoelectric electret 3 is obtained through the above steps.

[0049] A 100Hz sinusoidal force signal is used to excite the FEP composite film piezoelectric electret 3 to obtain d 31 is 50 pC / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com