Intelligent fault diagnosis method for numerical control machine

A fault diagnosis, CNC machine tool technology, applied in the direction of program control, computer control, general control system, etc., to achieve the effect of high diagnosis rate, low misjudgment rate, and strong fault diagnosis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

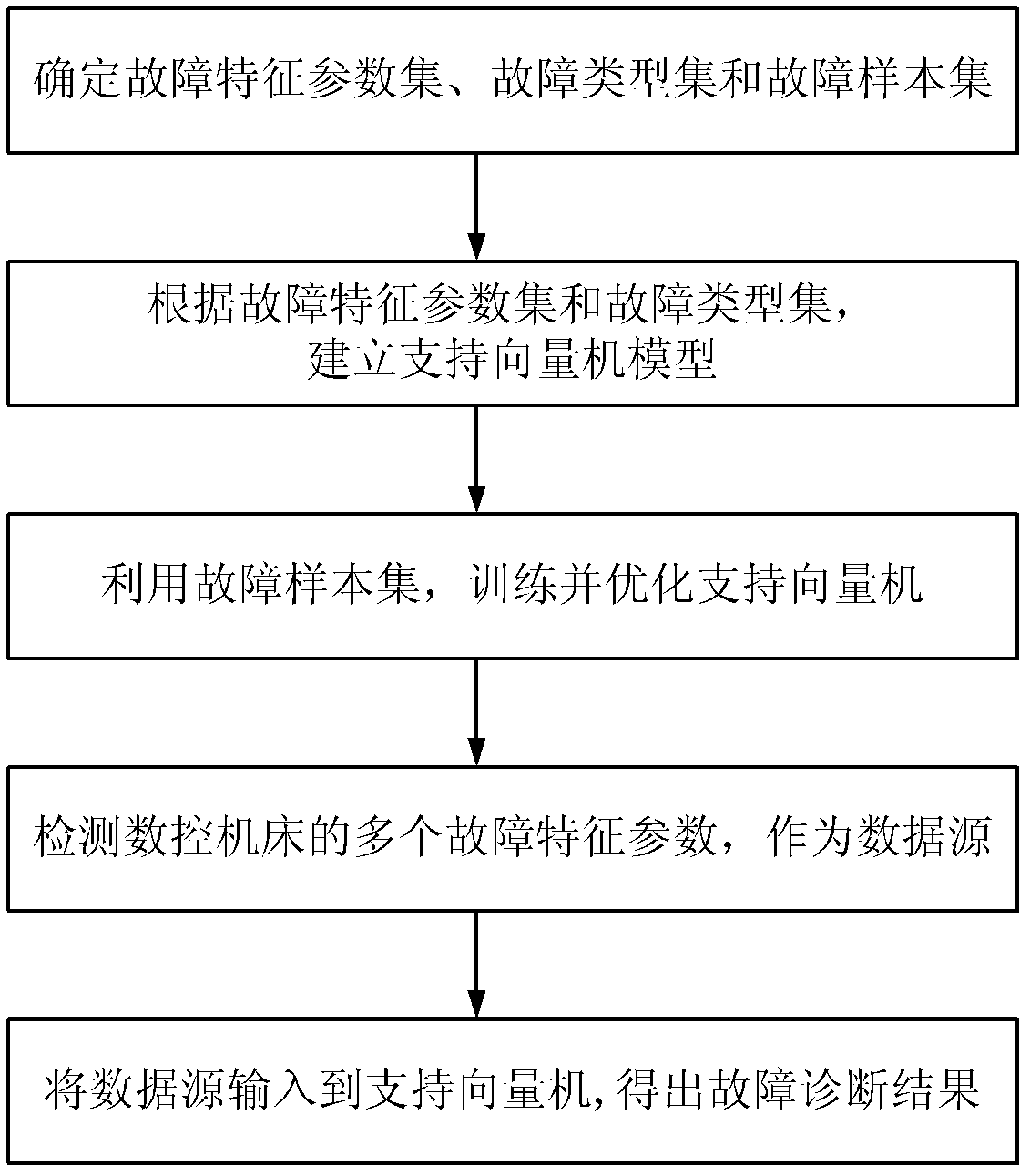

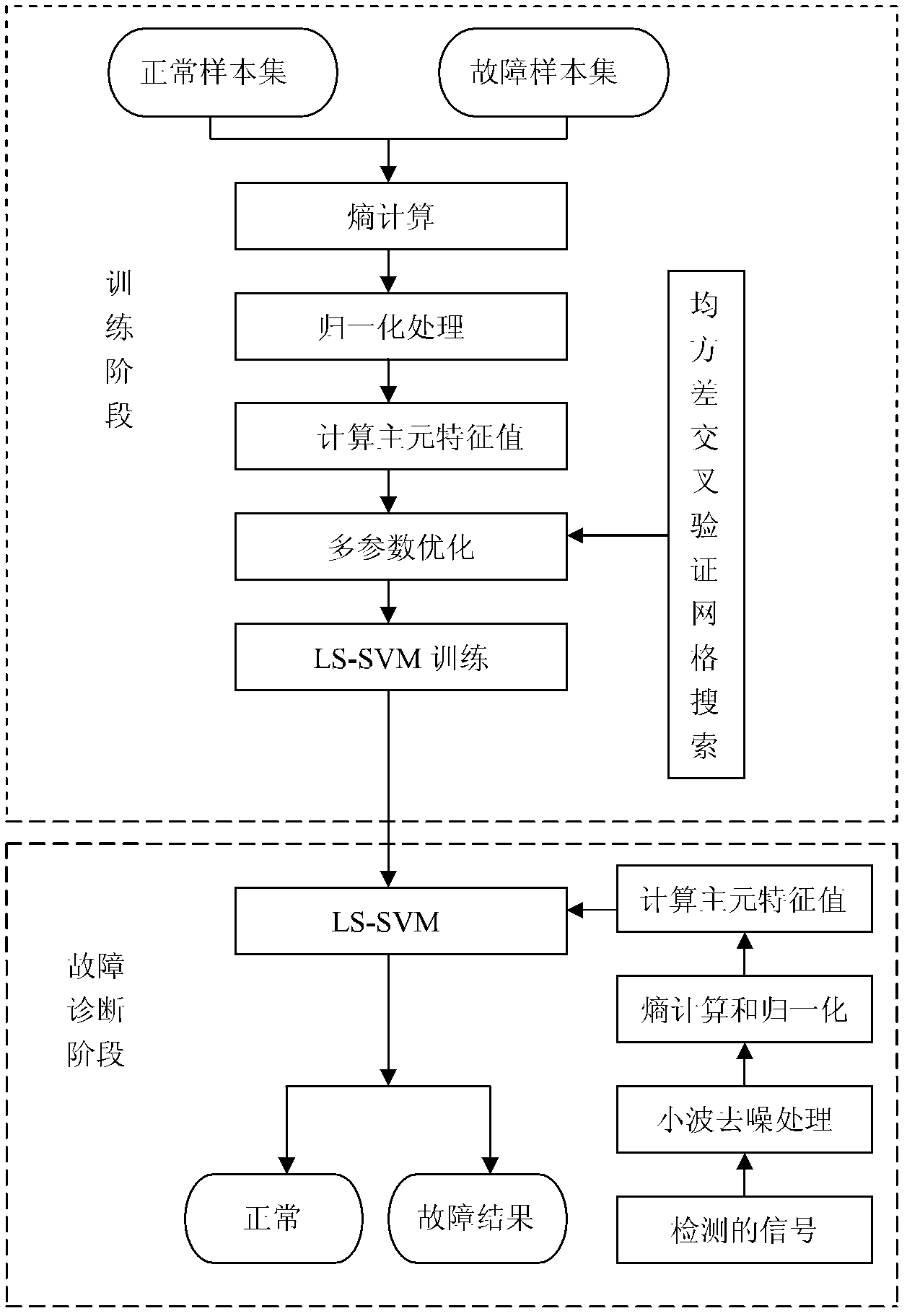

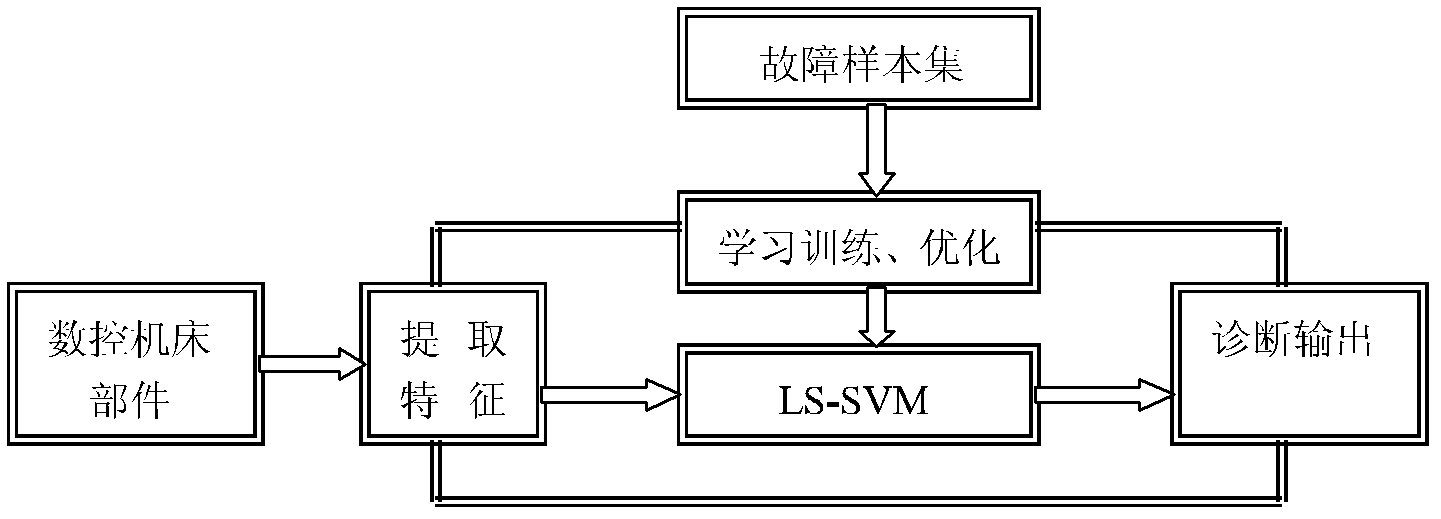

[0042] Such as Figure 1-3 As shown, the present invention provides a kind of intelligent fault diagnosis method of numerical control machine tool, comprises the following steps:

[0043] (1) Determine the fault characteristic parameter set, fault type set and sample set;

[0044] According to the occurrence mechanism and characteristics of the failure of the CNC machine tool components, the present invention uses six parameters as the failure characteristic parameters, namely, the temperature of the CNC machine tool, the output of the detection element, the high and low voltage current, the vibration frequency, the noise intensity and the servo control output voltage. The present invention adopts vector R to represent the fault characteristic parameter set, then ,in are six fault characteristic parameters.

[0045]According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com