A Five-Axis NC Interpolation Method Based on Tool Vector Smooth Compression

A vector compression and cutting tool technology, which is applied in the field of numerical control, can solve the problems of increasing the transmission burden of the system, not considering the tool vector interpolation, and large machining errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

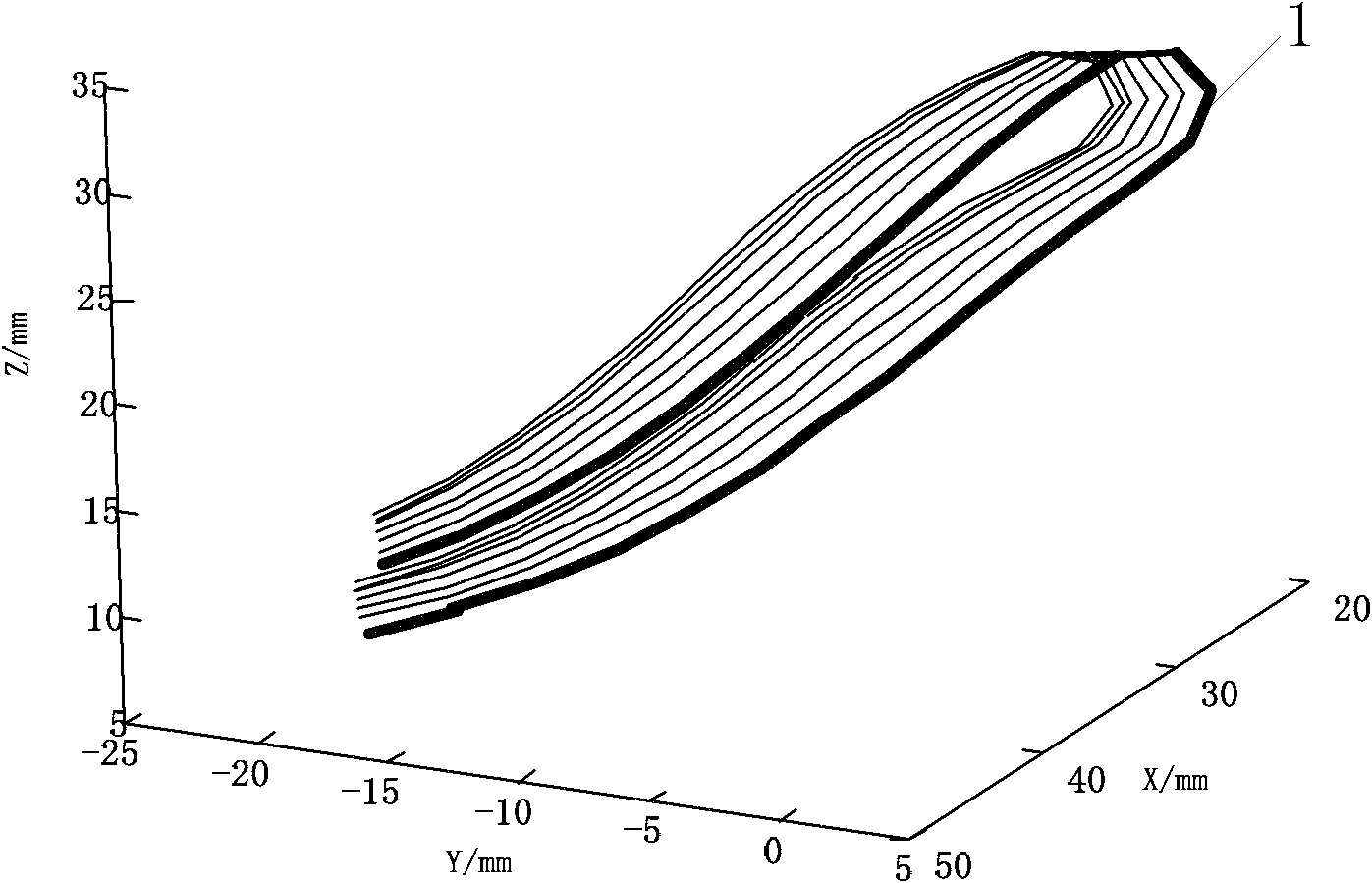

Examples

Embodiment Construction

[0043] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

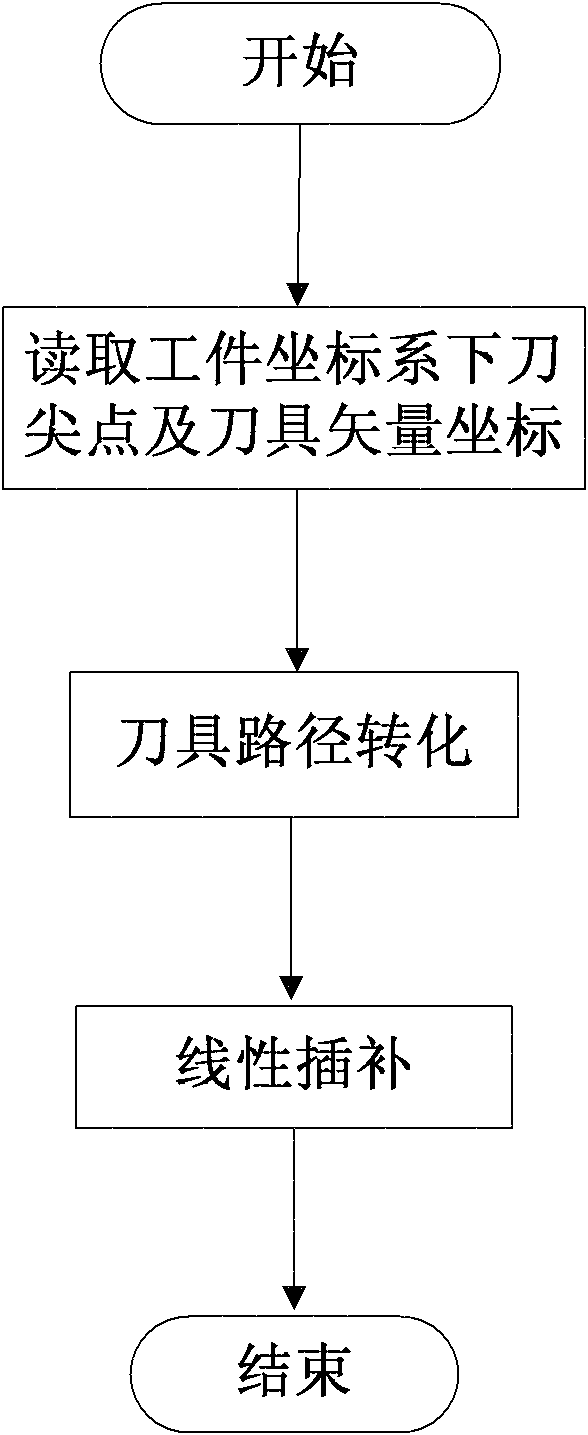

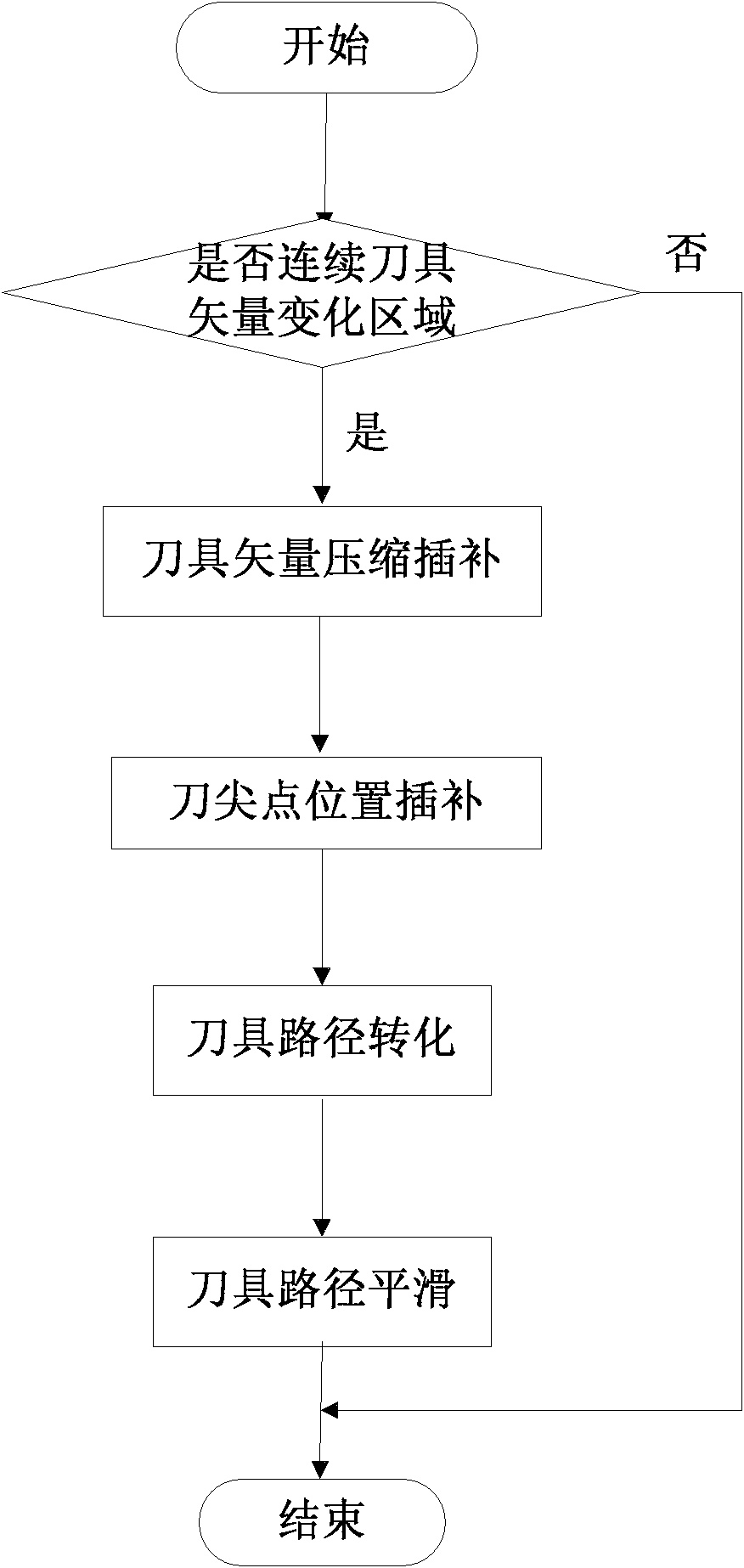

[0044] like figure 2 Shown, the inventive method comprises the following steps:

[0045] The five-axis numerical control interpolation method based on tool vector smooth compression of the present invention comprises the following steps:

[0046] According to the read-in NC machining program, judge whether any adjacent two tool vectors meet the conditions for continuous machining;

[0047] If the conditions of continuous processing are met, the tool vector compression interpolation and tool nose point position interpolation are performed; (tool vector compression interpolation: for a continuous tool vector change area, use the Lagrange multiplier method to fit, in The interpolation between any two tool vectors can be realized on the fitted tool vector curve; the position interpolation of the tool tip point: the position interpolation of any two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com