Solar-heating assisted salt melting system

A technology of auxiliary heating and molten salt system, applied in the field of molten salt equipment, can solve the problems of large fuel consumption and large environmental impact, and achieve the effects of increasing heat exchange time, convenient exhaust and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

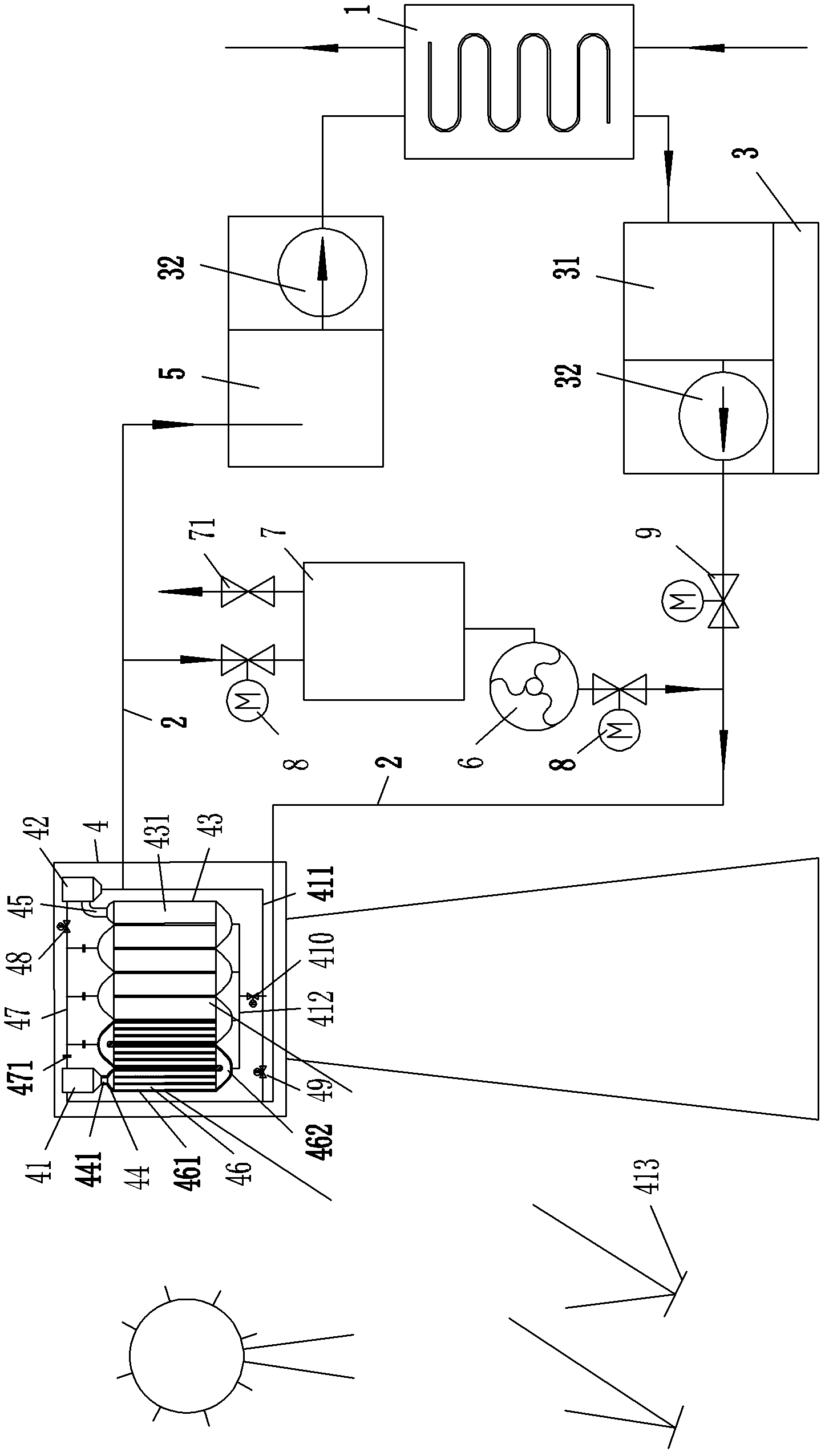

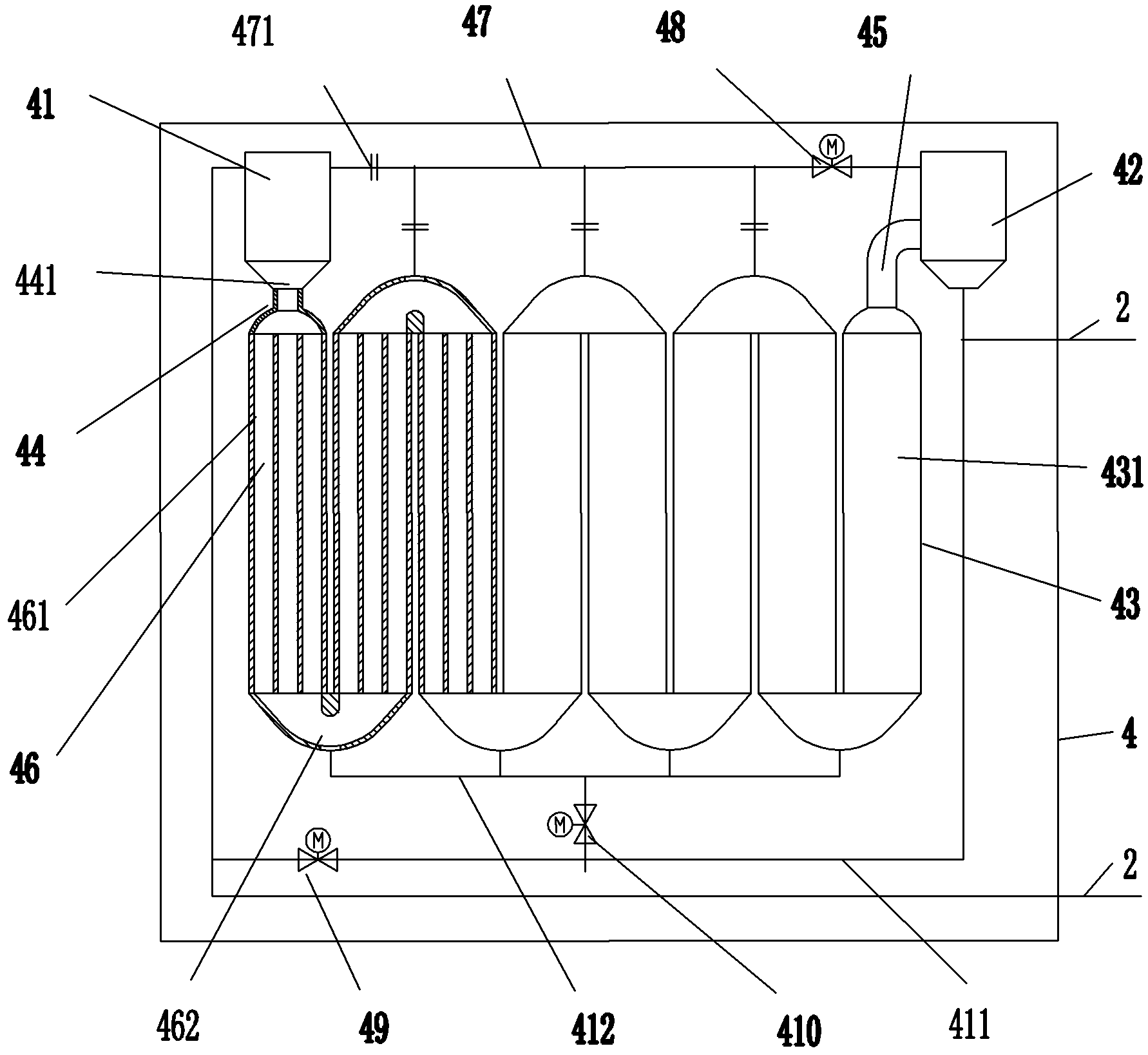

[0022] Embodiment 1, as attached figure 1 , attached figure 2 Shown: a solar-assisted heating molten salt system, including a molten salt furnace 3, a heat-using device 1, a solar heat-absorbing device 4, two heating pipes 2 and a high-temperature salt storage tank 5 with a molten-salt pump 32; The solar assisted heating molten salt system has a preheating device for preheating the heating pipe 2.

[0023] Described molten salt furnace 3 has the low-temperature salt storage tank 31 that has molten salt pump 32, and heat device 1 is a steam generator; The inlet of the heat absorbing device 4 is communicated, the outlet of the solar heat absorbing device 4 is communicated with the inlet of the high-temperature salt storage tank 5 through another heating pipe 2, and the outlet and the import of the heat-using device 1 are connected with the inlet and the inlet of the low-temperature salt storage tank 31 respectively. The outlet of the molten salt pump 32 of the high temperatur...

Embodiment 2

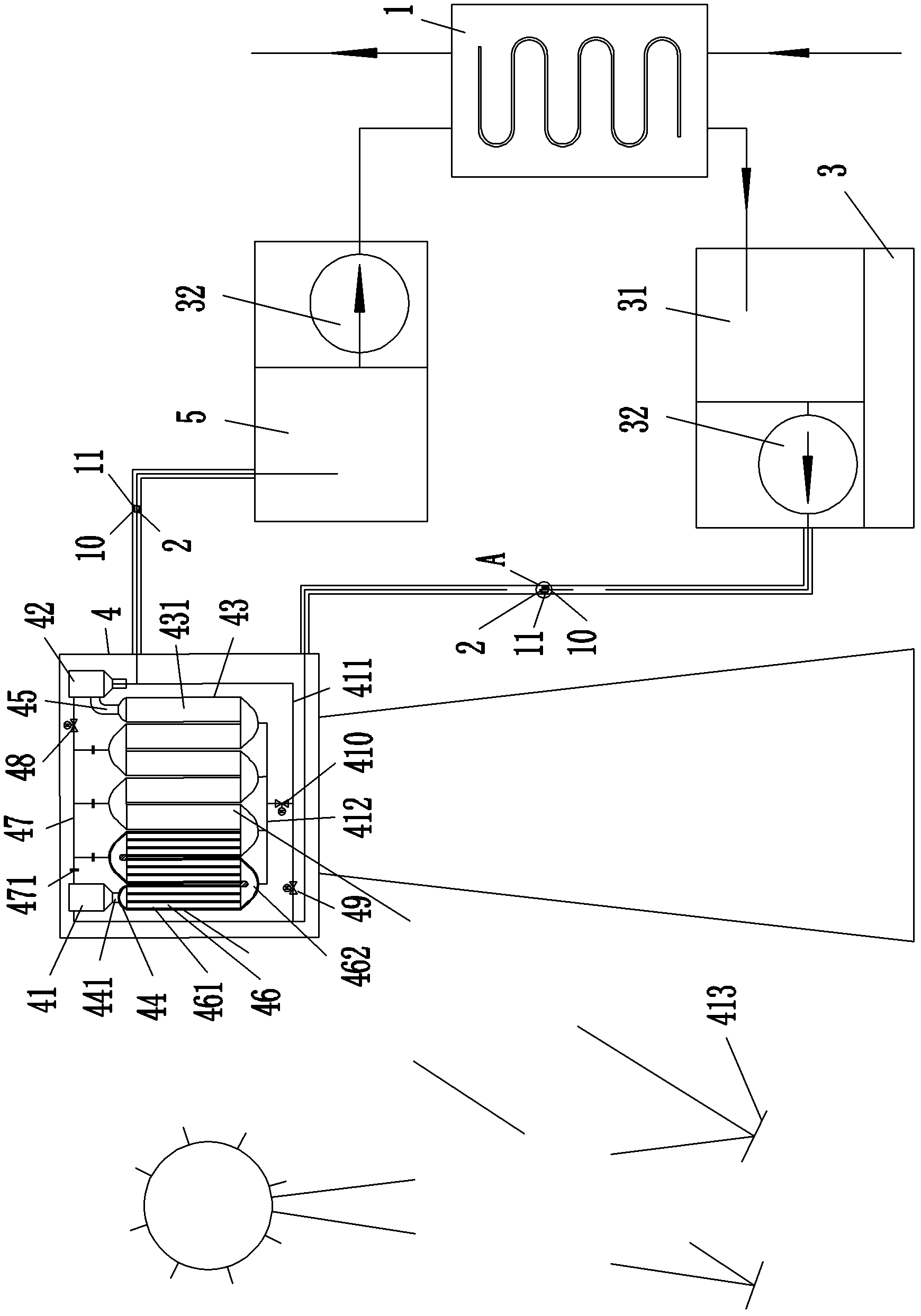

[0029] Embodiment 2, as attached figure 2 , attached image 3 , attached Figure 4 Shown: a solar-assisted heating molten salt system, including a molten salt furnace 3, a heat-using device 1, a solar heat-absorbing device 4, two heating pipes 2 and a high-temperature salt storage tank 5 with a molten-salt pump 32; The solar assisted heating molten salt system has a preheating device for preheating the heating pipe 2.

[0030] Described molten salt furnace 3 has the low-temperature salt storage tank 31 that has molten salt pump 32, and heat device 1 is a steam generator; The inlet of the heat absorbing device 4 is communicated, the outlet of the solar heat absorbing device 4 is communicated with the inlet of the high-temperature salt storage tank 5 through another heating pipe 2, and the outlet and the import of the heat-using device 1 are connected with the inlet and the inlet of the low-temperature salt storage tank 31 respectively. The outlet of the molten salt pump 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com